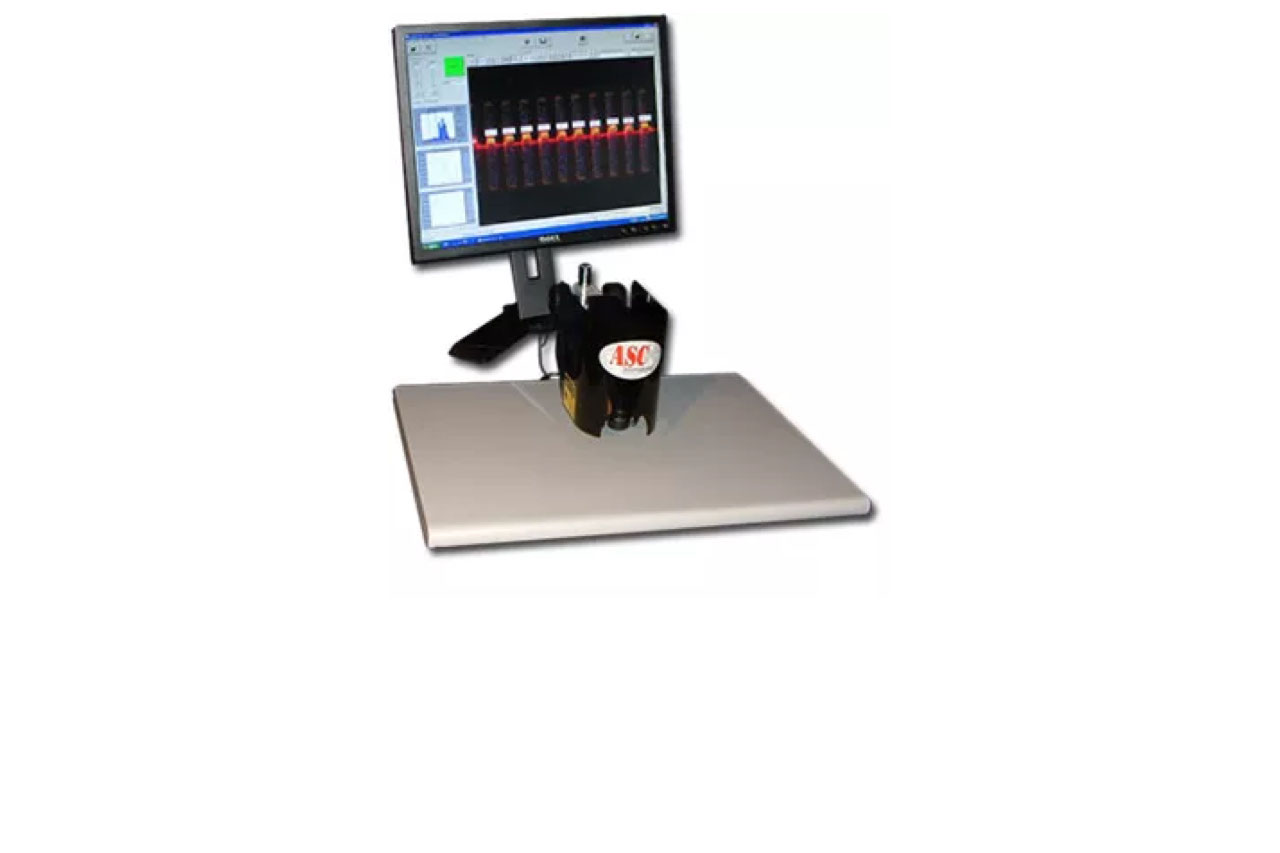

ASC International, a leading manufacturer of 3-D solder paste inspection (SPI) and automated optical inspection (AOI) systems, is pleased to offer the LaserVision SP3D Mini 3D Solder Paste Inspection system. The system offers the same level of overall measurement capabilities as the VisionPro SP3D, but utilizes a lower cost microscope platform and the ability for customers to supply their own PC if needed. The SP3D Mini sets the affordable boundary on reliable, low-cost SPI solutions.

The LaserVision SP3D Mini provides a powerful alternative to visual inspection of solder paste deposits, automatically calculating and storing critical printing characteristics in one click. The system enables ASC International to offer the same remarkable SPI technology found in their VisionPro and VisionPro AP Series models, but in an entry-level instrument. This makes LaserVision SP3D Mini ideal for manufacturers striving for better process control of the paste printing process, but working with a limited budget.

The SP3D Mini’s optional laser scanning feature provides 3D profiling capabilities along with added accuracy and repeatability due to increased data acquisition. This feature also provides a second layer of analysis to establish proper corrective actions based upon qualitative defect attributes.

For more information about ASC International, visit ascinternational.com.

About ASC International Inc

Since its foundation in 1992, ASC International has become a leading supplier of AOI and SPI systems and custom sensor technology integration. Headquartered in Minneapolis, Minnesota, ASC International provides customers with the service and support needed to realize the value of their investment in inspection and process control systems. ASC International’s customers include world-class organizations like Celestica, Creation Technologies, Flex, Honeywell, Jabil, Lockheed Martin, Plexus, Rockwell Automation and Sanmina-SCI to name just a few.