STI Electronics, Inc., a full-service organization including engineering, contract manufacturing and training services announces the acquisition of a new Laser Marking System.

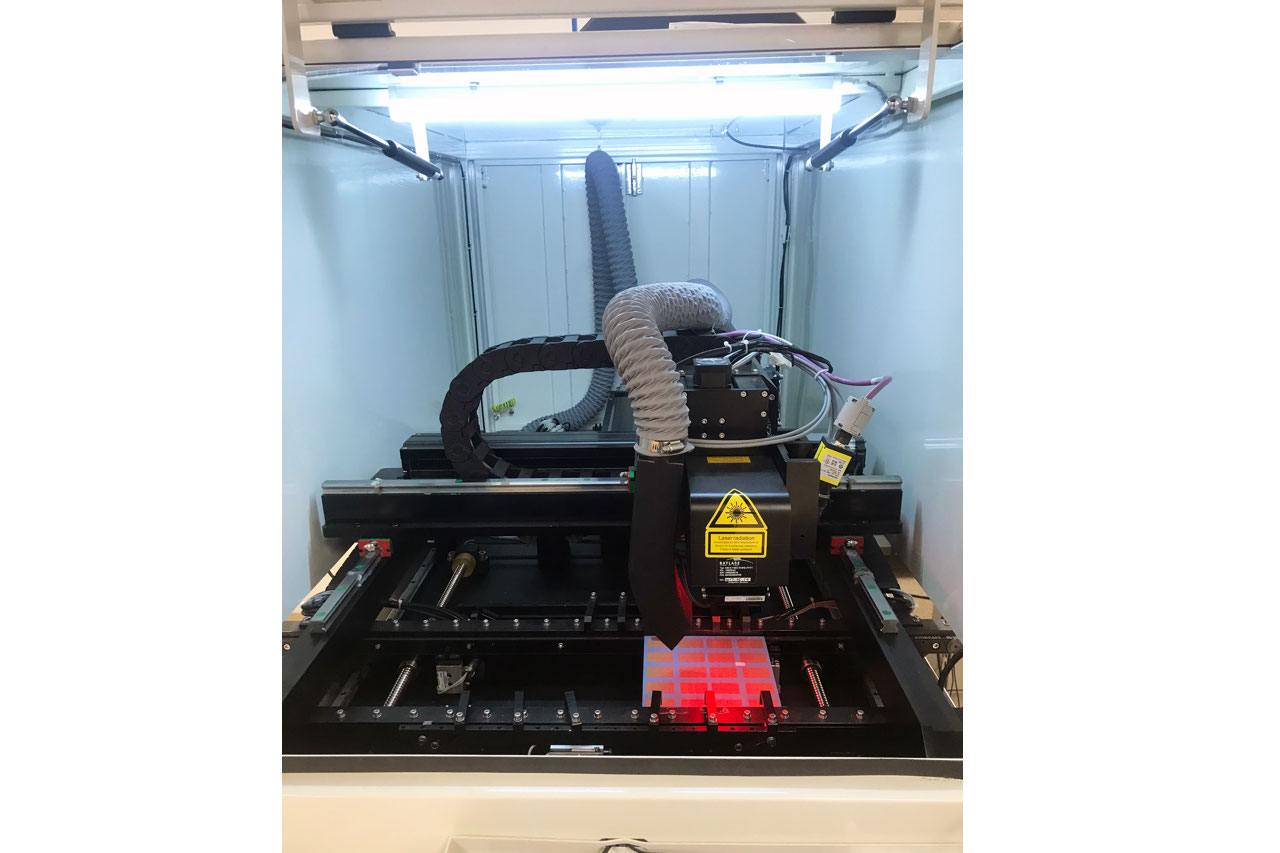

STI Electronics, Inc. is committed to bringing customers the latest, most advanced technology. One of the most recent additions to STI and its menu of services is Laser Marking using the Fancort LCD10C. Stickers fall off and ink fades, but laser marking provides a permanent mark that will stand the test of time.

Laser marking works by using a focused beam of light to mark the surface of a material. When the beam interacts with the material’s surface, it alters the material’s properties and appearance. This concentrated beam targets only a specified area, allowing the laser marking machine to create precise, high-quality, high-contrast marks that are easy to read or scan on virtually any surface. This feature makes laser marking ideal for applications where accuracy and permanency are critical to success.

Additional benefits include: essential, keeps track of products, improves quality, minimizes counterfeiting, eco-friendly, clean, affordable, energy efficient, easy to read.

All work performed using Fancort Industries LCD10C eliminates cost and downtime, provides permanent identification, complies with federal law, results in clean processing with minimal contamination and connects parts to the Industrial Internet of Things.

Contact STI Electronics, Inc. at stiusa.com to find out more about laser marking and how we can help you.