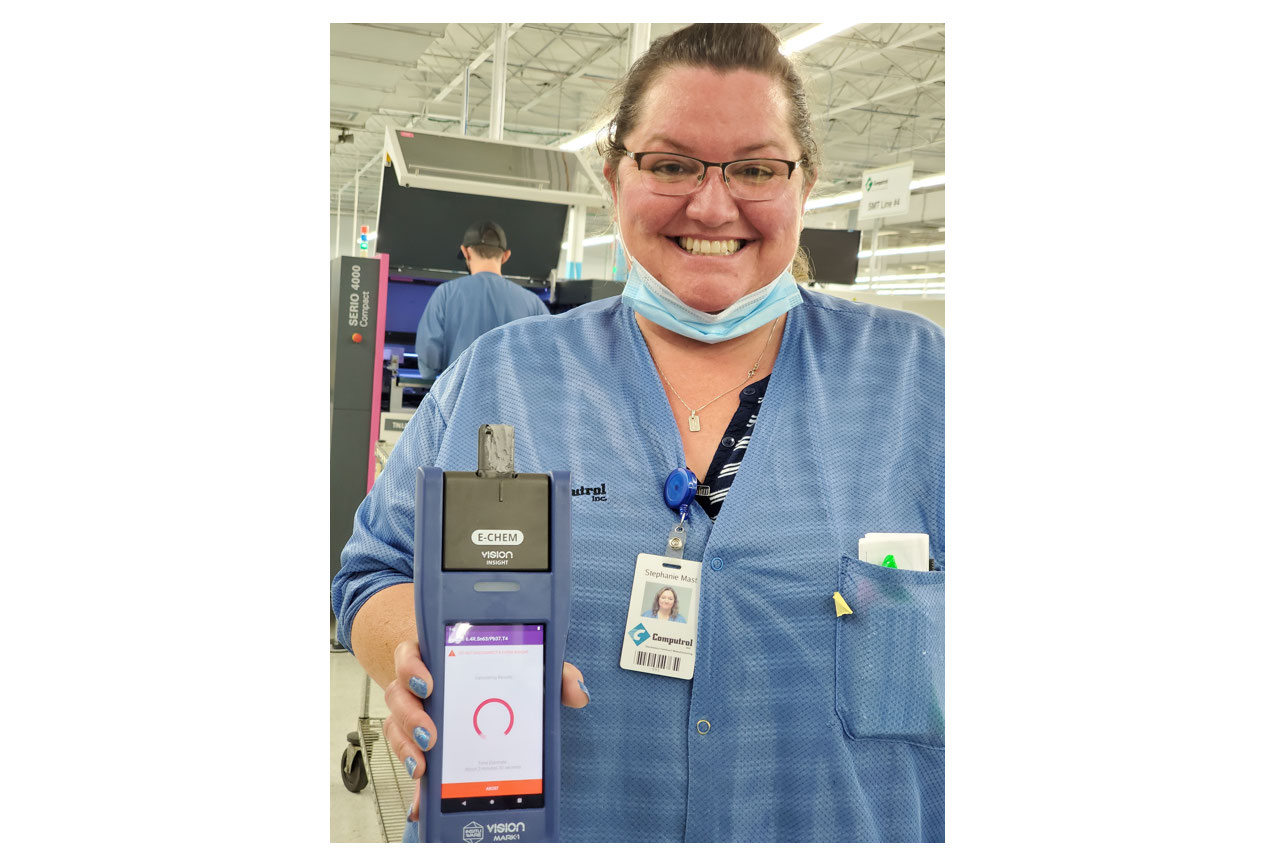

Computrol, Inc., a world-class provider of mid- to low-volume, high-mix electronic manufacturing services to OEMs, is pleased to announce that it has implemented the Vision MARK-1 hand-held diagnostic tool from Insituware LLC. The company made this investment for its customers to ensure its ongoing commitment to quality.

The revolutionary tool helps electronics manufacturers quickly detect and diagnose defects in solder paste right on the shop floor or prior to use, reducing costly mistakes and preventing manufacturing delays. “This tool was selected to give us consistent answers about our paste usability and consistency by analyzing the flux properties,” stated Michael Fric, Process Engineer, Computrol.

The Vision MARK-1 is powered by analytical sensors, machine learning, and cloud-based technology to bring materials control solutions right in your hand. With Insituware’s hand-held tools you can now to monitor your solder paste’s fitness for use in real-time to increase throughput, reduce costs, and improve reliability.

Insituware is revolutionizing the way we control materials!

For more information, visit insituware.com

Computrol continues to build on its core services and capabilities by investing in versatile, high-speed manufacturing equipment and technology, as well as continuing training programs for employees.

For more information, visit computrol.com