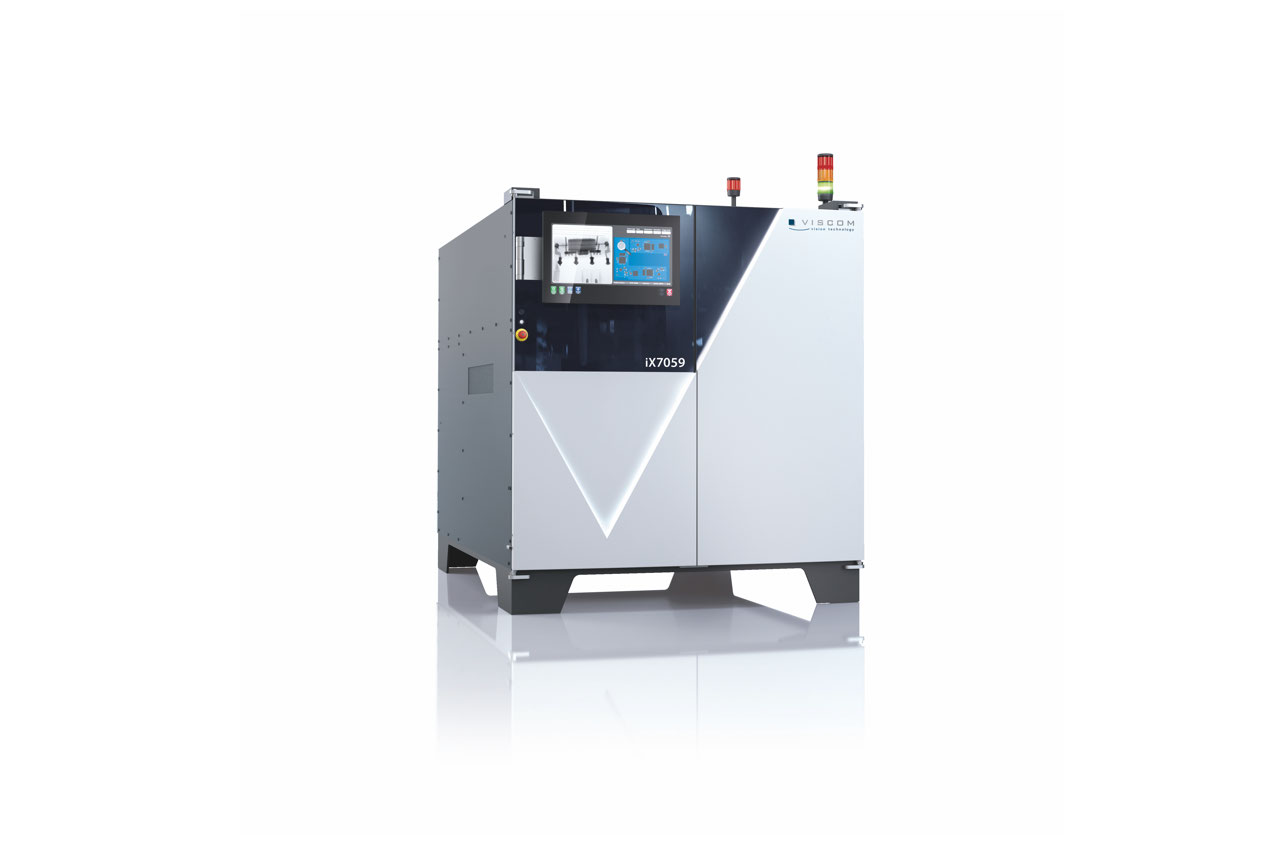

The new iX7059 Heavy Duty Inspection X-ray system is part of Viscom’s brand-new iX series for fast, fully automated inline X-ray inspection. The company developed a special transport system for the handling of workpiece carriers and soldering frames to ensure that heavy and encased assemblies can be transported and inspected in optimized cycle times. This special system can transport assemblies with dimensions of up to 500 x 500 mm and a weight of up to 40 kg. As a result, automatic X-ray inspection is gaining a foothold in trending sectors such as electric mobility, network infrastructure for the 5G telecommunications standard and in the area of renewable energies.

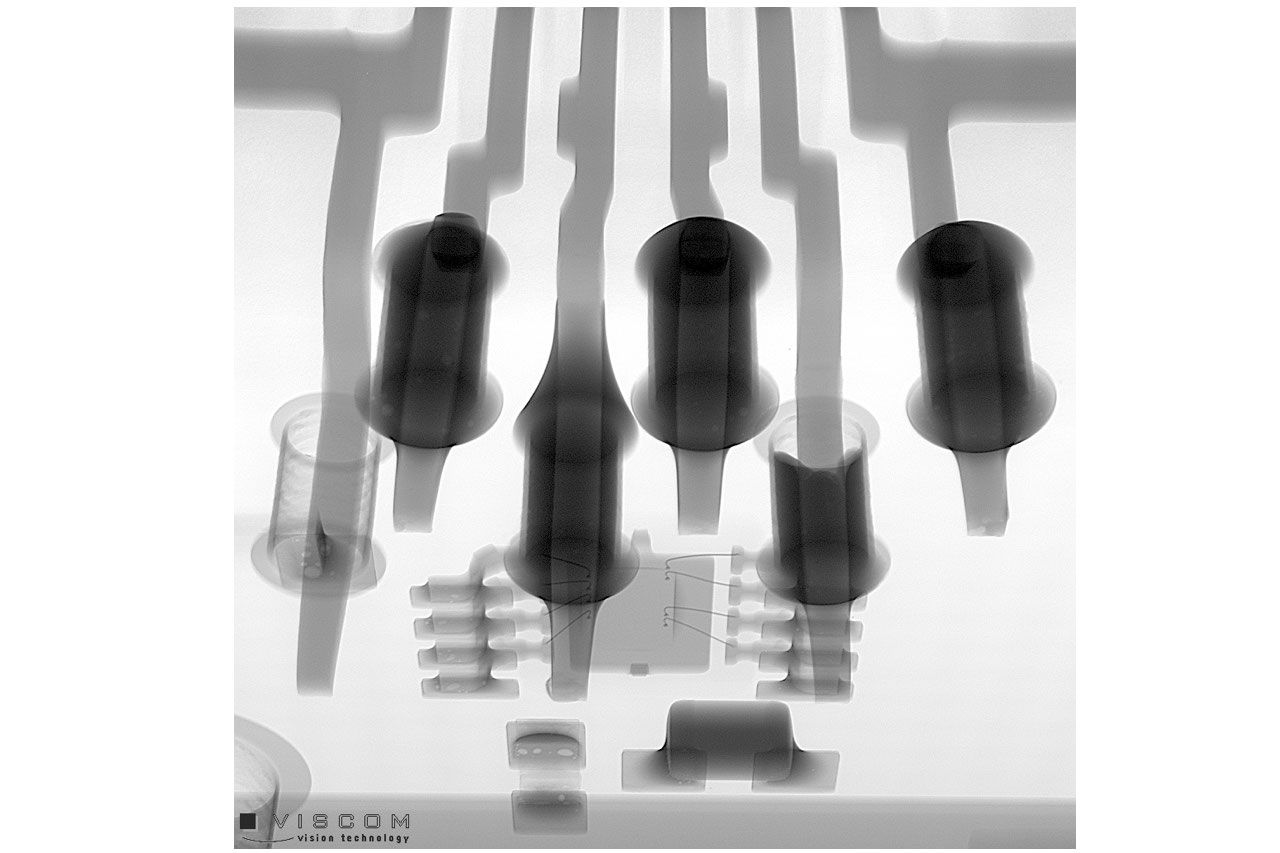

In order to ensure 100% product quality in high current and high voltage electronics, the heat generated as a result of the high currents has to be dissipated in a reliable manner. Large cooling elements, massive wire solder joints and power components, for example, are used to this end. Insufficient solder joints or voids within the soldering area can cause overheating in this situation and put the functionality, safety, and efficiency of the system at risk. A fully automated inline X-ray inspection that can be flexibly deployed for 2D, 2.5D, and 3D analyses is the first choice for reliable inspection.

The iX7059 Heavy Duty inspection system impresses with a resolution extending from 8 μm to over 30 μm, depending on the configuration. The complex inspection objects are irradiated with 130 kV or optionally 160 kV. The broad inspection scope of the inspection system extends to soldering defects, damage, twisted, missing, or incorrect components as well as concealed voids, blow holes/voids in surface solder joints and the degree of filling of THT solder joints.

The new “Evolution 5” image acquisition approach with the new T3 generation of flat panel detectors is used for highly accurate and fast 3D X-ray inspection. In combination with powerful computed tomography, all key defect features in sectional images are visualized in high detail to enable precise, convenient error detection. This simplifies verification, reduces false alarms, eliminates reworking and prevents product waste. Convenient operation of the system with the modern touchscreen monitor and fast, easy setup of inspection programs via the vVision or EasyPro operating software put the finishing touch on the system concept.

The compact, space-saving iX7059 Heavy Duty Inspection comes in a completely new system design that combines a distinctive style with high-quality materials and a robust housing. The system can also be seamlessly integrated into the production or final assembly line, and networking to implement smart factory concepts is also an option.

viscom.com

About Viscom

Founded in 1984, Viscom AG is one of the leading suppliers worldwide in the field of assembly inspection within electronics production. With its headquarters and production site in Hanover, Germany, the company develops, produces and sells high-quality inspection systems from the areas of AOI, SPI, AXI, MXI, bond inspection as well as CCI for protective coating inspection. The systems from Hanover set high standards in terms of accuracy and speed. The product range covers the complete spectrum of optical inspection and X-ray inspection for small- and medium-sized companies as well as for large series production. Viscom systems are used for 100% automatic inspection of electronic assemblies such as in the production of automotive electronics, aerospace technology or in the manufacture of telecommunications electronics.

Product development also focuses on customer-specific system developments and networking with other production processes for smart factory applications. In order to achieve this, Viscom AG increasingly invests in its own software and hardware development, which is constantly defining new standards in inspection technology.

International sales are handled by a broad network of its own subsidiaries, application centers, service centers and representatives. A service team of in-house technicians and application specialists commission Viscom systems worldwide, offering maintenance, conversion and modernization from a single source. In addition, system-specific training courses are offered for customers’ operators, programmers and maintenance personnel. Experienced engineers and technicians from the application and service departments share their expert knowledge with participants.

Viscom AG has been listed on the Frankfurt Stock Exchange since 2006 (ISIN: DE0007846867).

![NEPCON JAPAN [September] 2025 to Welcome 26,000 Trade Visitors and 350 Exhibitors at Makuhari Messe NEPCON JAPAN [September] 2025 to Welcome 26,000 Trade Visitors and 350 Exhibitors at Makuhari Messe](https://smttoday.com/wp-content/uploads/2025/07/PR-16-218x150.jpg)