~ Introducing Parmi DSI Equipment with the Flipper ~

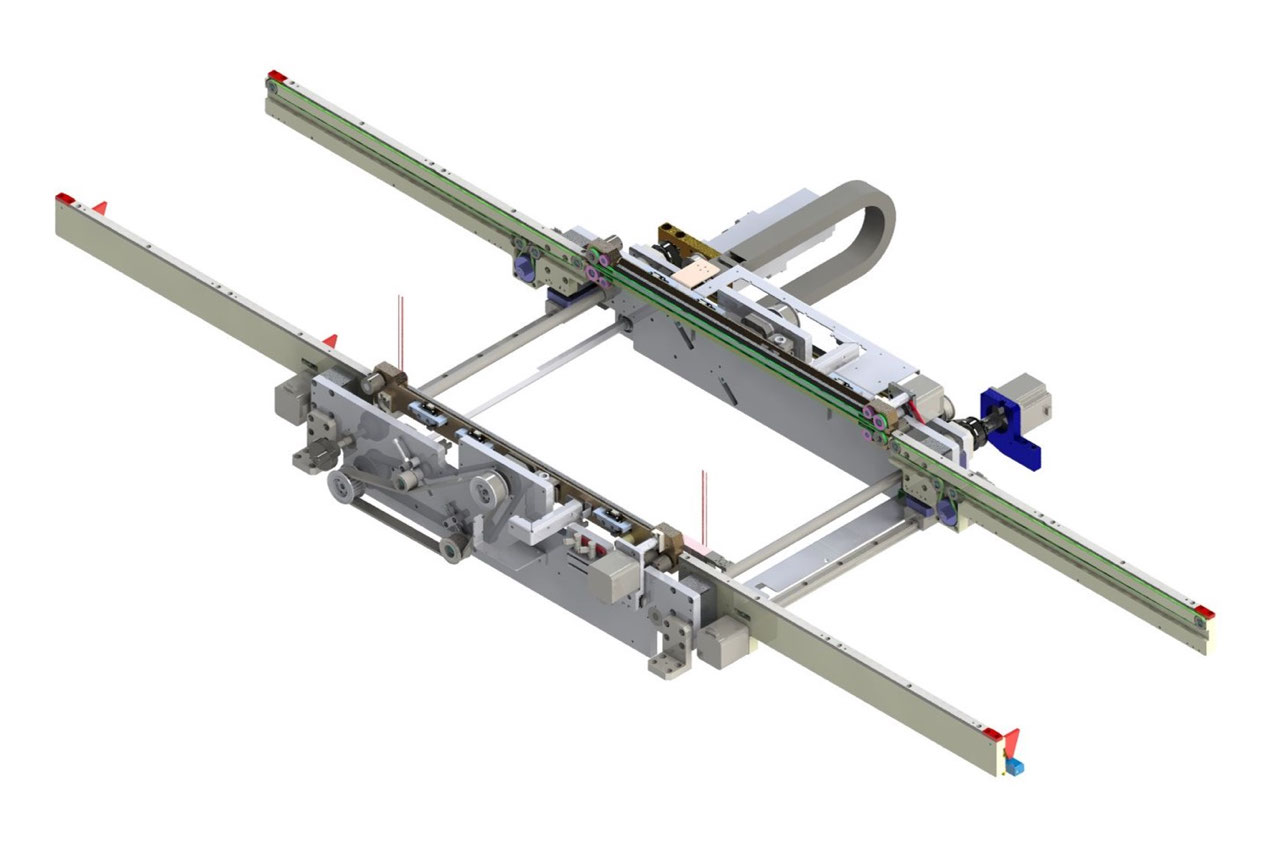

DSI is a function that inspects both the top and bottom of PCBs by inverting the boards inside the equipment. By installing a flipper inside the equipment, unnecessary processes are minimized and high speed inspection can be achieved.

Using the mixed model function, the top and bottom models are automatically changed and inspected. It provides accurate yield information of the model by separately managing the top and bottom model information and inspection results.

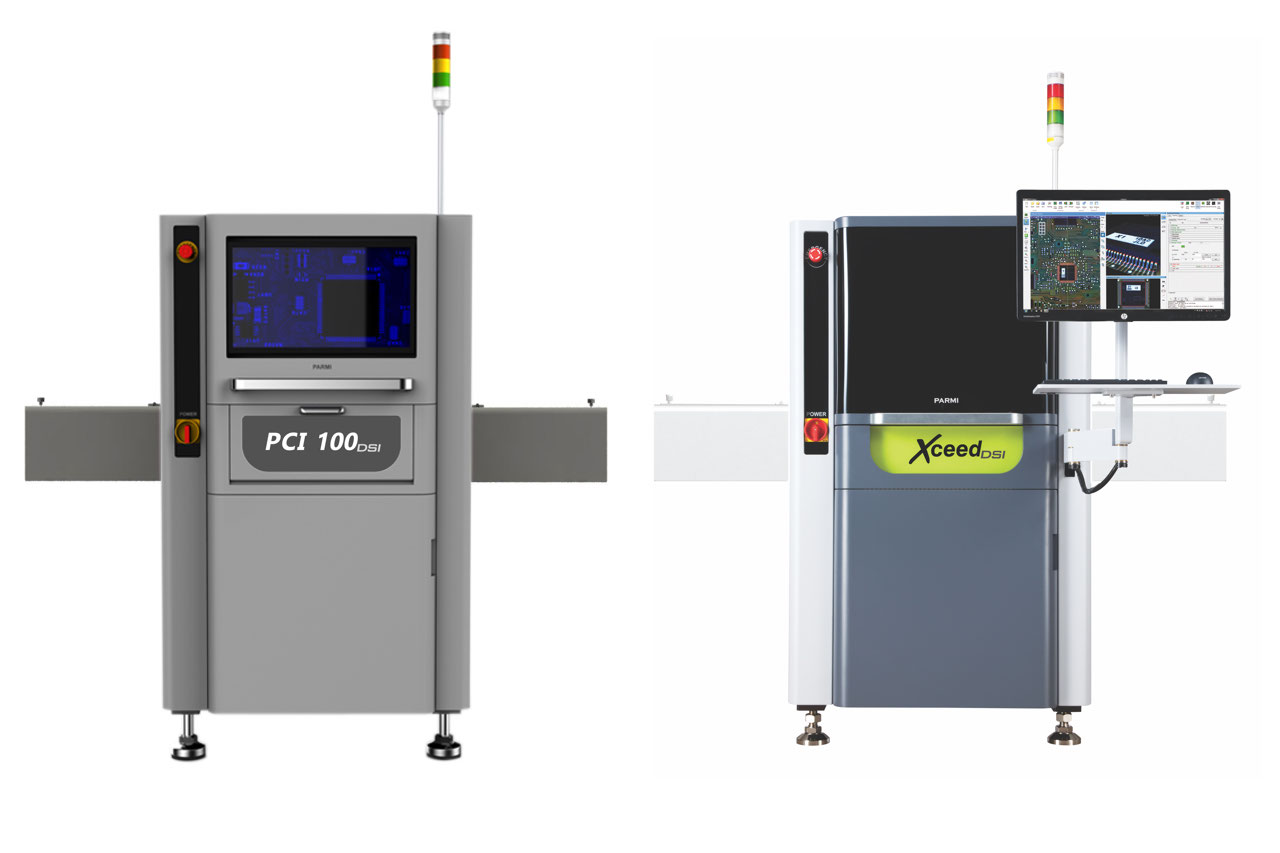

The DSI function is applicable to PARMI’s Xceed (3D AOI) and PCI 100 (Conformal Coating Inspection). Xceed is a 3D AOI with the industry’s highest inspection speed and accuracy.

PCI 100 is the industry’s first scanning-type conformal coating inspection system, capable of coating and coating thickness inspection.

For inquiries about Xceed DSI and PCI 100 DSI, please contact us through our website.