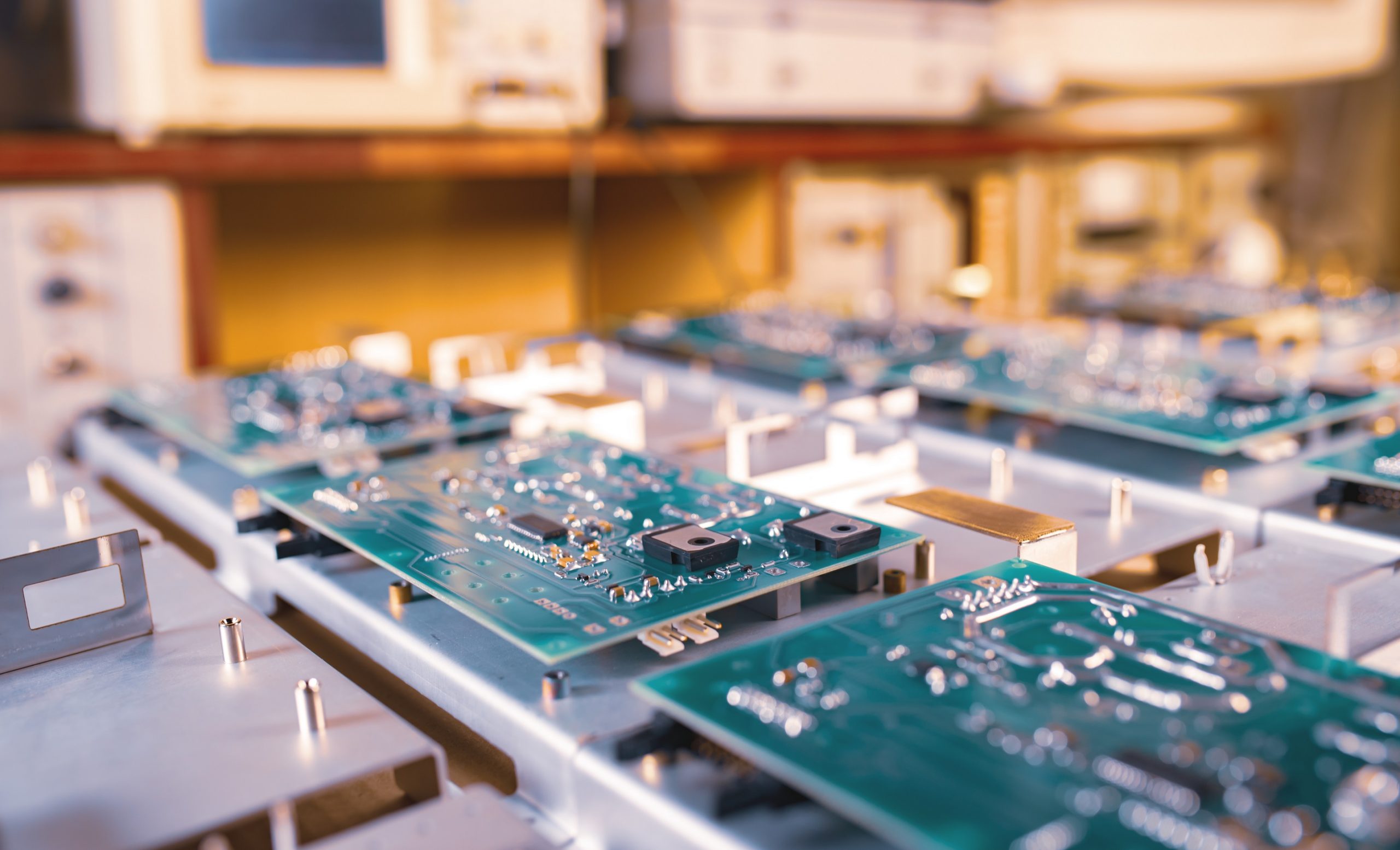

EcoCortec® is pleased to announce the world’s first Eco-Corr Film® ESD – biodegradable, compostable static dissipative films and bags powered by “Nano” VpCI®. This latest film technology is targeted mainly for electronics, telecommunications, packaging, and electric car industries seeking environmentally friendly packaging solutions. In anticipation of new EU regulations penalizing sales of non-recyclable plastic packaging materials, EcoCortec® is offering revolutionary, commercially compostable alternative to conventional polyethylene electrostatic dissipating (ESD) films. Eco-Corr Film® ESD products are high performance anti-static, corrosion inhibiting films and bags intended for disposal in a commercial composting environment.

They are designed for use in the protection of static sensitive multi-metal items such as electronics. The film contains permanent anti-static properties to immediately reduce or eliminate static buildup as long as the films or bags are in use, independent of the presence of humidity. Eco-Corr Film® ESD forms a molecular corrosion inhibiting layer on metal substrates and does not interfere with the physical or chemical properties of electronic components. The film and bags replace conventional rust preventatives such as oils and desiccants and allow the film to be used immediately without cleaning or degreasing. Eco-Corr Film® is commercially compostable, meaning that when the film is placed in a typical commercial composting environment it will disintegrate within months. The exact time is dependent upon the conditions and activity of the disposal environment (temperature, soil quality, activity of microorganisms). Eco-Corr Film® ESD is shelf stable and will not break down prematurely until disposed of in a proper composting environment.

FEATURES

• Contains Vapor phase Corrosion Inhibitors (VpCI®) to protect void spaces and recessed areas

• Contains permanent anti-static agent

• Does not affect optical properties

• Does not affect plastics used in electronics industry

• Does not contain free amines or harmful Prop 65 ingredients

• Commercially compostable packaging film that provides contact, barrier, and vapor corrosion inhibition

• Meets NACE TM0208-2008 standard for corrosion protection

• Meets German TL-8135-002 standard for corrosion protection

• Complete replacement for non-degradable and inferior blend films

• Static decay rate conformance to MIL-PRF-81705D

• No ill effects on solderability of PCB, meeting the requirements of IPC-JSTD-003C, Am1 (Edge Dip Solderability Tests)

A Czech subsidiary of one of the world’s three largest car manufacturers, selected Eco-Corr Film®as a biodegradable substitute to reduce the amount of conventional plastic packaging they use. They tested Eco-Corr Film® as part of their new “green” logistics project aimed at decreasing plastic consumption.

Eco-Corr Film® was tested as part of the pilot project of packaging car parts for shipment to their plant in Pune, India. Several tests were conducted for compliance with strict conditions for transport in sea containers. Quality control did not show any damage or traces of corrosion on the components wrapped in Eco-Corr Film® upon arrival in India. In order to test if the film were able to be composted according to plan, the staff built compost bins near the plant. After six months, the foils had largely disintegrated in the compost bins, helping them to eliminate plastic waste. Eco-Corr Film®successfully replaces conventional plastic films they used previously and provides the same effective corrosion protection. Composted packaging material will be used as soil improver at the plant’s logistics park. Manufacturer was able to cut the amount of conventional plastic packaging in half thus eliminating a significant amount of plastic waste (as much as 500 kg [1102 lbs] per month).

To learn more about Eco-Corr Film® ESD including antistatic and mechanical properties, please visit: www.cortecvci.com/

Cortec® Corporation is the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies for Packaging, Metalworking, Construction, Electronics, Water Treatment, Oil & Gas, and other industries. Our relentless dedication to sustainability, quality, service, and support is unmatched in the industry. Headquartered in St. Paul, Minnesota, Cortec® manufactures over 400 products distributed worldwide. ISO 9001, ISO 14001:2004, & ISO 17025 Certified. www.cortecvci.com