Tackling the reliability and data rate demands of 100 gigabit ethernet (GbE) and 400 GbE optical transceivers in next-generation cloud and hyperscale data centers, Henkel has developed LOCTITE® STYCAST® OS 5101, a dual cure adhesive for optimal, precise optical lens and component alignment during the in-line assembly process. The new material builds on the company’s growing portfolio of data center optics products and has been designed to provide excellent alignment accuracy for maximum light transmission in high-speed optical transport network solutions.

“As cloud-scale and hyperscale data centers continue to evolve to meet demanding data management bandwidth expectations, data center interconnections are becoming increasingly more powerful and efficient,” says Henkel Global Head of Data & Telecom Market Strategy, Wayne Eng, noting the complexity of today’s high power, high value optical modules. “Transceivers are the key building blocks for high-speed data transmission and their assembly integrity is more critical than ever before to protect device investment, ensure long-term reliability, and optimize function.”

Tim Munks, Senior Principal Analyst at Omdia agrees, adding, “Transceiver development has dramatically accelerated to keep pace with the exponential data processing demands, as is evidenced by the quick move from 100 GbE to 400 GbE to now 800 GbE modules,” he says. “Over the next four years, we expect the unit volume CAGR for 400 GbE to be greater than 200% and more than 300% for 800 GbE. Optical communication efficiency is the key to meeting the expectations for cloud, video, gaming, work and learn from home applications – and it is only getting more intense. Transceiver reliability, signal integrity and lower loss optics are critical.”

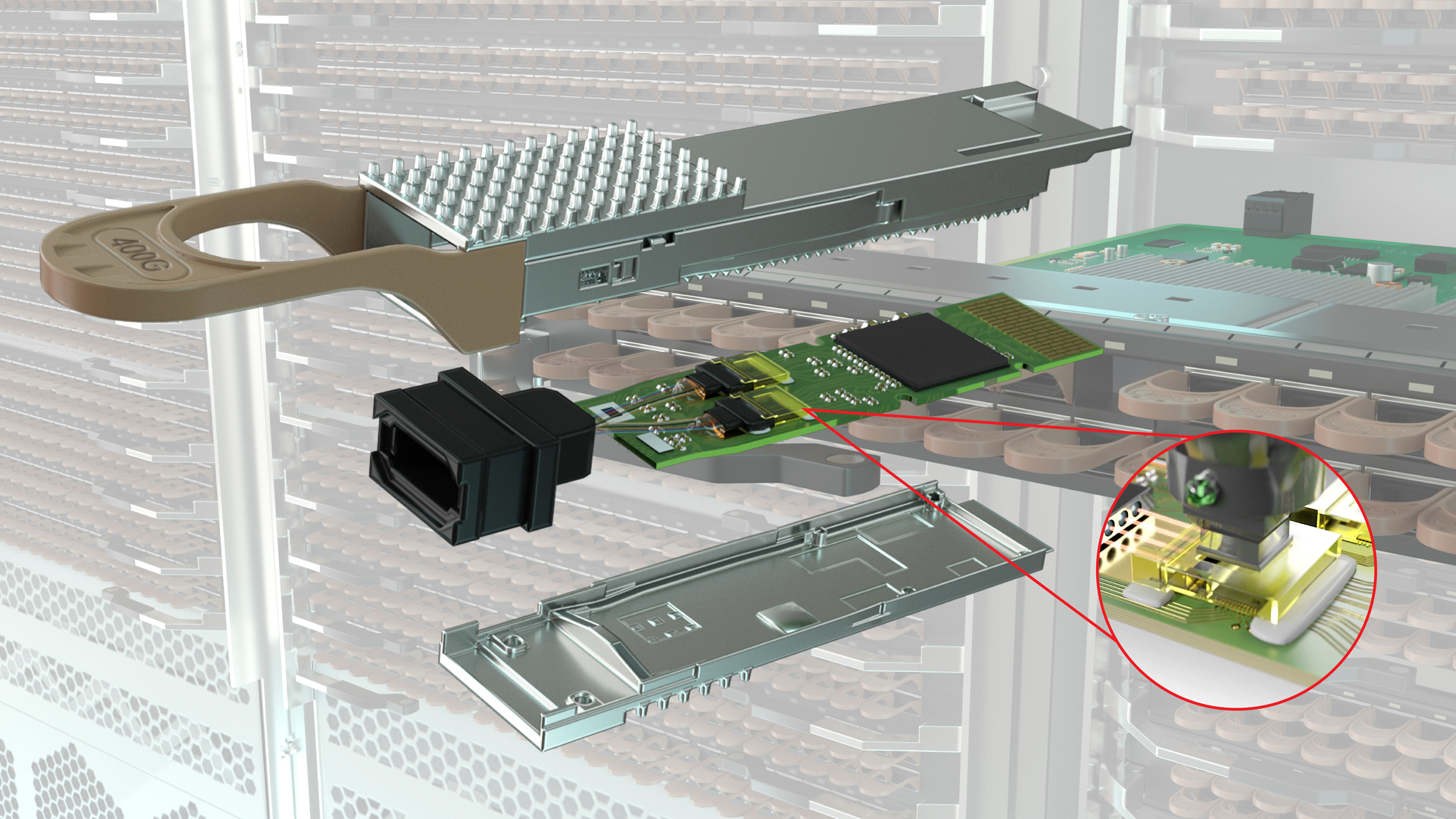

In order for optical signals to transmit with minimal loss, meticulous alignment of lenses and optical components is required. After a first stage UV partial cure, LOCTITE STYCAST OS 5101 allows precise positioning of optical lenses within the transceiver optical sub-assembly and, once final thermal curing takes place, the material maintains its dimensional stability to ensure accurate lens position while in operation. In addition to high reliability as confirmed by high temperature/high humidity, thermal shock and high temperature storage testing, internal results also indicate that material properties of LOCTITE STYCAST OS 5101 are capable of delivering other important performance metrics for 100GbE to 400GbE transceiver optical bonding, such as:

- Maximized optical signal through positional integrity and dimensional stability:

- Low coefficient of thermal expansion (CTE); CTE below Tg of 20 PPM/°C

- Volume shrinkage <1%

- Low moisture absorption (0.8%)

- Strong adhesion to various substrates

- High UPH capability with energy savings:

- First phase UV cure achieved in 40 seconds using only 1W UV (other available materials require as much as 4W for 40-sec. cure)

As Eng explains, the impressive material characteristics combine to enable alignment precision and integrity for minimal signal loss, which is the holy grail of efficient optical networks. “The tight tolerance for lens and component movement leaves no room for error,” he says. “Achieving demanding dimensional stability and reliability standards required for next-generation optical components and transceivers is possible with LOCTITE STYCAST OS 5101.”

With the development of LOCTITE STYCAST OS 5101, Henkel’s portfolio of optical device assembly solutions, which also includes structural adhesives, protective materials, and die attach products, is now among the most comprehensive on the market. For additional information, visit Henkel’s Material Solutions for Optical Transceivers page or call 1-800-562-8483 to order a sample or speak with a technical specialist.