NanoFlowX, the leader in ultra-thin protective nanocoatings for electronics, will exhibit at the 2026 APEX EXPO in Booth 4032, showcasing live demonstrations of its breakthrough PCB waterproofing technology that is helping manufacturers unlock six-figure annual savings by switching away from traditional conformal coatings.

As electronics manufacturers face rising labor costs, long process times, and capital-intensive coating equipment, NanoFlowX offers a faster, simpler, and far more profitable alternative. By eliminating masking, spray programming, and high-cost machinery, NanoFlowX enables manufacturers to dramatically reduce operating expenses in combined labor, equipment, and process savings, all while improving durability and throughput.

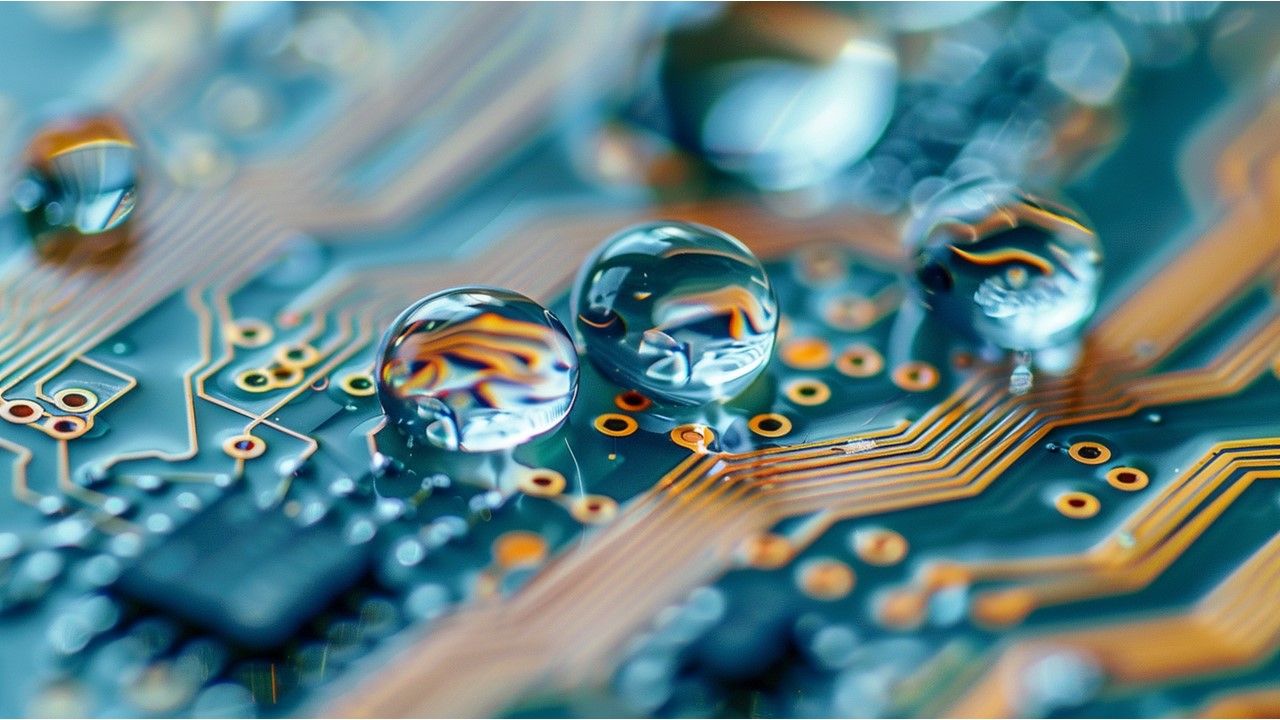

At the show, NanoFlowX will demonstrate V2, its flagship waterproofing solution capable of achieving IP67/IP68-level protection in minutes. The process is remarkably simple:

- Dip each PCB into the NanoFlowX coating solution

- Apply heat at 80°C for 5–10 minutes

- Done, fully protected and ready for the next step in the assembly process

There are no long hours of masking, no $200,000–$400,000 conformal coating machines to purchase, and no need to reprogram boards to hit precise spray zones. The result is a streamlined process that accelerates production, reduces errors, and significantly lowers total cost of ownership.

Unlike traditional acrylic, silicone, or parylene conformal coatings, NanoFlowX nanocoatings are 100% reworkable, making repairs and modifications fast and cost-efficient. The ultra-thin coating delivers complete 360-degree protection on even connectors, all while maintaining electrical performance and serviceability. Application is substantially faster than conformal coating processes, and the finished protection is more durable at a fraction of the cost.

Designed for mission-critical electronics, NanoFlowX coatings protect against water ingress, dust, humidity, salt fog, and corrosion, while adding virtually no weight or thickness. Applications include printed circuit boards, sensors, optics, batteries, communications equipment, drones, ruggedized servers, and electronics used in defense, aerospace, industrial, and other harsh environments.

Technologies featured at APEX EXPO 2026 will include:

- V2 Waterproofing Solution – A rapid two-step process using a five-second dip followed by a five-minute heat cure to deliver IP-rated protection against water, corrosion, dust, and humidity.

- VX3 Non-Fluoro Coating – An environmentally friendly, non-fluorinated nanocoating providing protection comparable to traditional V3 coatings for electronics up to 10A or 48V.

- V4 High-Dielectric Electronics Coating – An industrial-grade solution for electronics operating above 10A and up to 240V, engineered for extreme corrosion

Visitors to Booth 4032 can see the coating process firsthand and learn how NanoFlowX technologies help manufacturers improve durability, simplify production, and protect electronics used in harsh operating conditions.

For more information or to schedule a meeting, visit www.nanoflowx.com/pages/apex2026.