Workpiece carriers are a decisive factor for the efficiency and repeatability of selective soldering processes. Eutect GmbH has therefore developed a sophisticated carrier concept that is individually tailored to the requirements of modern electronics manufacturing. With many years of experience and in-depth soldering and materials expertise, Eutect supplies workpiece carriers with integrated titanium soldering masks that are not only technically impressive but also economically attractive.

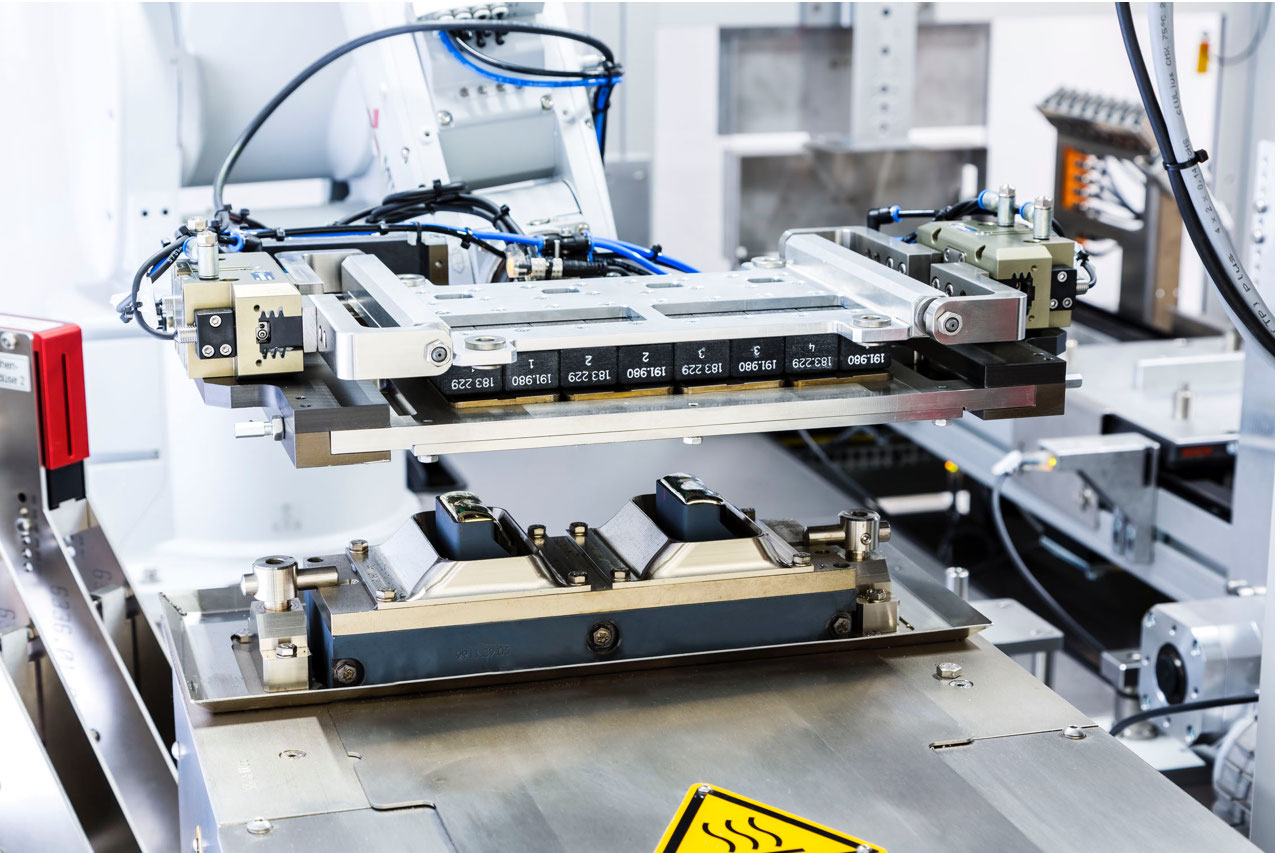

A key problem with conventional workpiece carriers (WPC) is their high weight and accuracy. Many carriers are too heavy, which means that handling systems and 6-axis robots have to be designed and dimensioned for the higher weight. In addition, most standard workpiece carriers for selective soldering processes are not precise enough to ensure the necessary repeatability and process reliability. To compensate for this disadvantage, Eutect uses so-called satellite WPCs. At the center is a product-specific, lightweight satellite carrier that is placed on a base carrier and can be picked up directly from the conveyor belt by the robot. This allows assemblies to be transported flexibly and in a weight-optimized manner to the respective processes within the cell.

The satellite carrier can also be equipped with functions such as integrated titanium masks or product queries. It therefore serves as the basis for reliable processing with high repeat accuracy. After the soldering process, it is positioned on the original base carrier again. This modular concept clearly separates logistical and product-specific requirements and reduces both the weight during handling and the complexity of the design. This means that robots with a lower load capacity can also be used efficiently, creating additional savings potential. A particular advantage is its adaptability. The lightweight satellite carriers are cost-effective to procure and quick to convert. This makes them ideal for product or variant changes. At the same time, it is no longer necessary to keep complete workpiece carriers for each individual product variation or to set up complex buffer or storage systems. This reduces investment costs. In addition, space and storage requirements can also be reduced.

Eutect has extensive expertise in the design and production of workpiece carriers, titanium soldering masks, and matching soldering nozzles for selective mini-wave soldering. This is the result of many years of project experience and in-depth technological expertise. Unlike many market participants, Eutect does not view the carrier and mask as separate components, but rather as integral parts of a precisely coordinated manufacturing process. Development takes place in-house, ensuring both technical precision and maximum adaptability. All carrier solutions are systematically matched to the soldering technologies, automation components, and handling modules used, contributing significantly to process stability and reproducibility.

This in-depth understanding is based on a large number of successfully implemented applications in various industries, including the automotive industry, medical technology, consumer goods industry, and defense technology. This broad experience is continuously reflected in the ongoing development of carrier systems. Eutect follows a modular development process that ranges from analysis and design to functional prototypes and production-ready series solutions, always with the aim of providing customized, economical, and process-reliable carrier concepts.

This in-depth understanding is based on a large number of successfully implemented applications in various industries, including the automotive industry, medical technology, consumer goods industry, and defense technology. This broad experience is continuously reflected in the ongoing development of carrier systems. Eutect follows a modular development process that ranges from analysis and design to functional prototypes and production-ready series solutions, always with the aim of providing customized, economical, and process-reliable carrier concepts.

About EUTECT

For almost 30 years, soldering and joining systems have been developed, manufactured, installed, and programmed at EUTECT as well as at customers operating worldwide. The Swabian team of experts offers an extensive, constantly evolving module construction kit for process solutions in the field of soldering.

Process-related and commercially optimal modules for the task description will be selected from a wide variety of soldering-technology process modules and combined into proven stand-alone, revolving, or inline production designs for complete solutions.

The EUTECT module construction kit shows that a slim, individual solution comprising proven building blocks for a customer product’s task description can often be achieved via individual modules or free combinations.

A technologically comprehensive, innovative EUTECT technical center is available for optimal solution through evaluation or the manufacture of A-B-C prototypes ready for serial production.