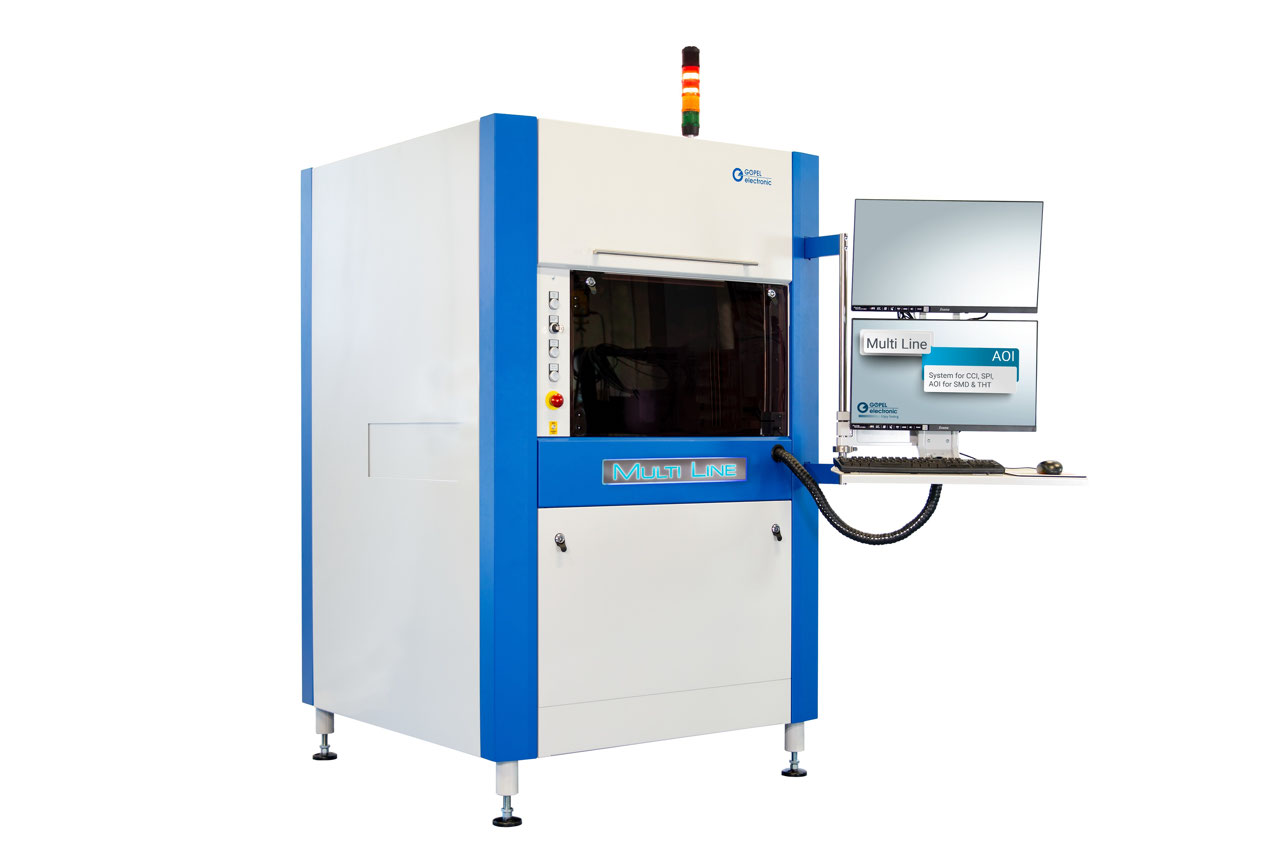

Conformal coating is indispensable for electronics used in changing climatic conditions and in safety-related applications. The coating reliably protects sensitive PCBA from moisture, dust, and temperature changes—especially in applications such as automotive, aerospace, and energy systems. Coating defects and deviations from the coating plan can now be reliably detected automatically with the new Multi Line CCI inspection system from GÖPEL electronic. With the new CCI camera module, even more accurate and faster inspection results can now be achieved.

Thanks to innovative oblique view cameras, integrated paint thickness measurement, and a component clearance of up to 120 mm, the system offers significantly more flexibility and precision in the quality check of protective coatings on PCBA. The Multi Line CCI impresses with UV illumination and a telecentric color camera that delivers razor-sharp images. New are the up to eight optional oblique view cameras, which open up additional perspectives. They enable precise inspection of areas that are difficult to see, such as connectors.

Another new development is a 3D coating thickness measurement system that is integrated directly into the system. It allows the actual layer thickness to be measured at various points on the PCBA, as required by the IPC standard. This is a significant advantage for applications with tight tolerances or increased quality requirements. The system not only checks for the presence of the coating, but also its correct thickness. With a component clearance of up to 120 mm, the Multi Line CCI now offers significantly more space for PCBAs with tall THT components or carriers with tall handles. When paint thickness measurement is activated, 80 mm of component clearance is still available.

The fully automatic Multi Line CCI can inspect from both above and below. This means, for example, that dip-coated PCBAs can be inspected on both sides at the same time without having to turn the PCBA over. Fully automatic return of the PCBAs below the inspection level is also possible. Thanks to the latest technical equipment, maximum inspection coverage is achieved: The CCI camera module of the Multi Line CCI is equipped with a high-resolution color camera (resolution 8 µm/17 µm), telecentric optics, and high-power UV LEDs for illumination from multiple directions with a wavelength of 365 nm. In addition, the camera module can be equipped with eight oblique view cameras to reliably inspect pins of connectors from multiple viewing angles, for example.

The programming of the CCI inspection is designed to be extremely user-friendly: the system can be set up in a matter of minutes using CAD data and paint plans. Both the painted and unpainted areas of the PCBA are inspected.

About GÖPEL electronic

GÖPEL electronic develops and manufactures innovative electrical and optical test, measurement, and inspection equipment for electronic components and printed circuit board assemblies as well as industrial and automotive electronics systems. GÖPEL electronic has four business units:

– Automotive Test Solutions

– Embedded JTAG Solutions

– Inspection Solutions AOI-AXI-SPI-IVS

– Industrial Function Test

The company is active worldwide, with its own subsidiaries as well as through distributors, and generated sales of approximately 40 million euros in 2023 with 240 employees.