What Are BGA Rework Stations?

Definition and Core Functionality

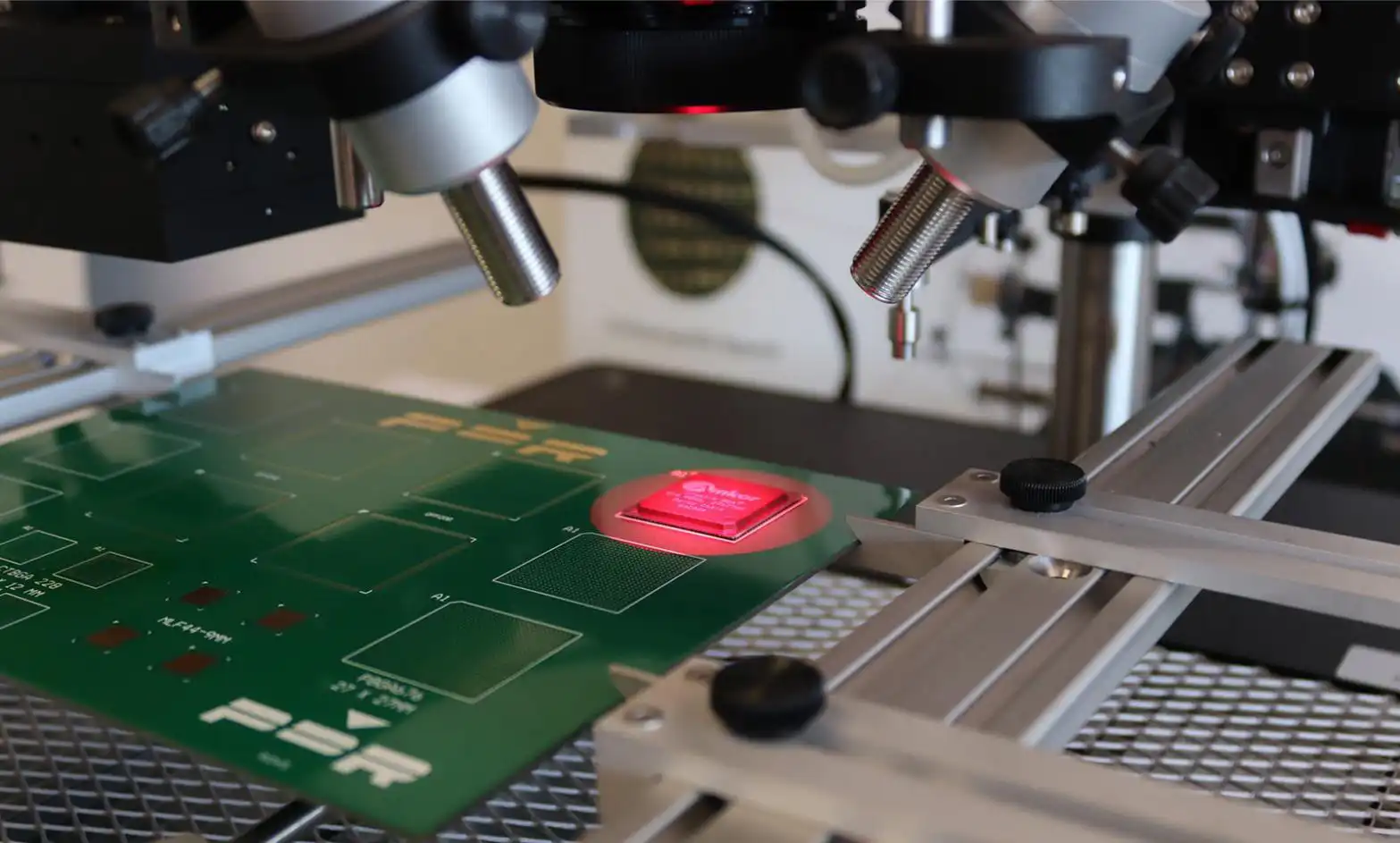

A BGA Rework Station is a highly specialized tool used to repair or replace Ball Grid Array (BGA) components on printed circuit boards (PCBs). These systems are essential for restoring or modifying complex electronics where solder joints are hidden beneath integrated circuits.

Understanding Ball Grid Array (BGA) Technology

The BGA packaging method uses an array of solder balls on the underside of a chip, creating strong electrical and mechanical connections. This design improves performance, signal integrity, and space efficiency, but it also requires precise tools for removal and reinstallation.

Why BGA Rework Is Critical in Modern Electronics Manufacturing

As electronics continue to shrink in size and increase in complexity, reworking BGAs manually becomes impractical. BGA rework stations like those from PDR Rework ensure:

- Controlled heat application

- Accurate alignment

- Consistent, repeatable reflow results

- This precision prevents costly PCB damage and maximizes yield.

How BGA Rework Stations Work

Step-by-Step Overview of the Rework Process

-

Component Removal | The system evenly heats the target chip to reflow solder balls.

-

Pad Cleaning | Excess solder is removed for a clean surface.

-

Reballing or Component Replacement | A new component or re-balled chip is aligned using optical systems.

-

Reflow Soldering | Controlled heat fuses the solder joints.

-

Inspection | Optical or X-ray verification confirms joint quality.

The Role of Heat, Vision, and Precision in BGA Rework

Accurate temperature control and optical alignment are the foundations of successful BGA rework. PDR’s systems use infrared heating and digital imaging to ensure every chip is placed with micron-level accuracy.

Core Components of a High-Performance BGA Rework Station

1. Advanced Heating Systems

PDR’s infrared heating technology delivers non-contact, uniform thermal energy to both the component and PCB. Unlike hot air systems, infrared eliminates the risk of disturbing adjacent parts.

2. Optical Alignment and Vision Technology

Using precision optics, PDR stations enable operators to align BGAs accurately, even with micro-pitch or fine-pitch components.

3. Thermal Profiling and Process Control

Integrated closed-loop thermal feedback ensures consistent heating profiles, preventing over- or under-reflow.

4. PCB Handling and Support Mechanisms

PDR designs stable, vibration-free fixtures that prevent board warping and maintain planarity during rework.

PDR Rework: Innovating the Future of BGA Rework Stations

Company Overview and Global Reputation

With decades of experience, PDR Rework is recognized globally for pioneering infrared rework technology. Their systems are trusted by leading manufacturers, repair labs, and defense contractors.

Commitment to Precision and Repeatability

Every PDR system is engineered to deliver consistent results, cycle after cycle. This reliability ensures minimal rework errors and maximum production uptime.

The PDR Infrared Technology Advantage

Unlike conventional hot air systems, PDR’s IR rework technology offers superior control, even heating, and zero airflow disturbance — ideal for densely populated boards.

Why Choose PDR BGA Rework Stations?

Infrared Heating Excellence

PDR’s non-contact IR heating provides uniform energy distribution across the entire rework zone, eliminating thermal gradients and component stress.

Non-Contact, Non-Destructive Rework Process

Since infrared heat is applied without airflow, sensitive components remain undisturbed, preventing solder splatter and component drift.

User-Friendly Interface and Software Automation

Operators can easily create, store, and execute thermal profiles using intuitive touchscreen interfaces, ensuring repeatable and traceable results.

High Reliability and Low Maintenance

PDR rework systems are built for industrial longevity, featuring self-diagnostics, durable components, and minimal calibration requirements.

Applications of BGA Rework Stations in Electronics

Consumer Electronics and Smartphones

PDR rework stations are widely used for repairing smartphone motherboards, gaming consoles, and laptops, where compact BGAs dominate.

Automotive Electronics and Industrial Control Units (ECUs)

Automotive systems demand high-reliability repairs. PDR’s closed-loop IR control ensures safe rework of sensitive automotive ECUs.

Aerospace and Defense Electronics

Precision, traceability, and reliability are non-negotiable in aerospace. PDR’s systems meet these rigorous standards.

R&D and Prototype Development Labs

Researchers and engineers use PDR stations to refine soldering processes and validate new designs efficiently.