BTU International, Inc., a leading supplier of advanced thermal processing equipment for the electronics manufacturing market, will exhibit at productronica 2025, taking place November 18-21 at Messe München in Munich, Germany. Visitors can find BTU at Hall A3, Stand 103, where the company will showcase its newest model, the Aurora 125N.

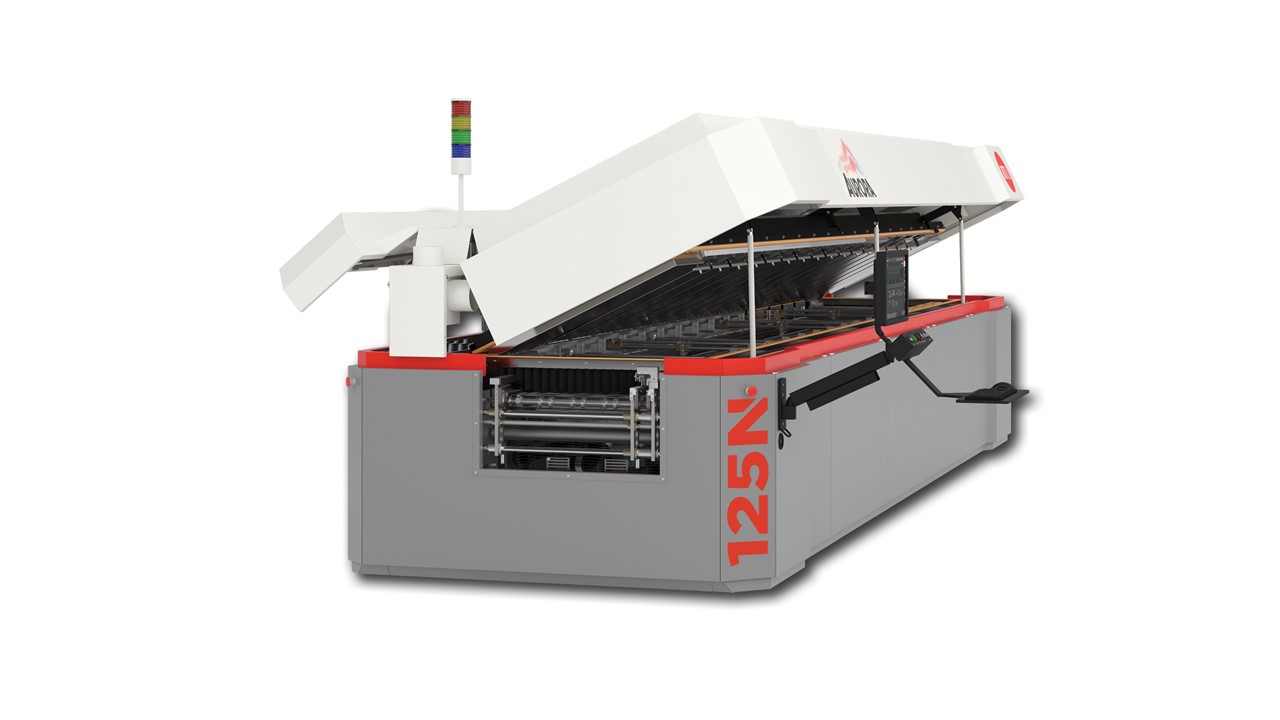

The Aurora 125N is the latest addition to BTU’s high-performance Aurora family, delivering advanced reflow technology in a compact footprint. With the launch of this model, the Aurora platform now includes four distinct systems — the 125N, 175N, 200N, and Aurora Pro — each optimized for different throughput requirements and manufacturing environments.

Engineered for flexibility, speed, and efficiency, the Aurora 125N offers exceptional thermal performance and precise process control, making it an ideal solution for high-mix electronics manufacturing. The system features factory-configurable heating and cooling zones, smart power management, and optimized gas flow for superior thermal uniformity. Maintenance is simplified with enhanced accessibility, and the optional Aqua Scrub™ flux management system helps extend uptime while supporting environmentally responsible operation.

“Energy efficiency and sustainability are at the core of the Aurora platform’s design,” said Rob DiMatteo, General Manager of BTU International. “Our goal is to give manufacturers the thermal performance and process control they need while reducing total cost of ownership and minimizing their environmental footprint.”

Attendees are invited to visit BTU International at Hall A3, Stand 103 to see the Aurora 125N and learn more about how the complete Aurora platform can help manufacturers meet today’s production challenges.

To learn more about BTU International and the Aurora reflow oven family, meet with the BTU team at productronica or visit www.btu.com.

About BTU International

BTU International, a wholly-owned subsidiary of Amtech Group (Nasdaq: ASYS), is a global supplier and technology leader of advanced thermal processing equipment in the electronics manufacturing market. BTU’s high-performance reflow ovens are used in the production of SMT printed circuit board assemblies and in semiconductor packaging processes. BTU also specializes in precision controlled, high-temperature belt furnaces for a wide range of custom applications, such as brazing, direct bond copper (DBC), diffusion, and sintering. BTU has operations in Westford, Massachusetts, and Shanghai, China, with direct sales and service in the U.S.A., Asia and Europe. Information about BTU International is available at www.btu.com.