Viscom SE, a pioneer in automated optical and X-ray inspection, will present the latest innovation in AI solutions from November 18–21 in Munich. At Booth A2.177, the company will demonstrate how its latest developments are transforming inspection processes.

For manufacturers aiming at flawless production, Viscom’s technologies provide a decisive advantage. The company’s systems have long relied on advanced algorithms, exacting 3D measurement, and detailed image analysis. These strengths are now extended through Viscom’s AI platform, known as vAI, which introduces intelligent features such as AI based verification, AI supported image processing and fast inspection program generation at the productronica.

“vAI goes far beyond the standard idea of AI”, explains Daniel Petereit, Head of Marketing at Viscom SE. “It is a comprehensive toolbox that gives our customers the resilience they need to meet current production requirements while positioning themselves for the next generation of electronics manufacturing. With AI we help them secure both efficiency and quality in a sustainable way.”

A major attraction at productronica 2025 will be Viscom’s new software function that redefines how inspection programs are created: vAI ProVision. With the introduction of its AI-powered software feature Viscom is setting a new standard in the creation of 3D AOI and 3D AXI inspection programs. By embedding AI into the vVision Software, inspection plans can now be generated and optimized almost entirely automatically: faster, smarter, and more efficiently than ever before. In just minutes, a ready-to-run inspection program is available, delivering maximum inspection depth, exceptional quality, and driving lasting improvements in production performance.

Visitors of the show will also see Viscom’s latest inspection systems in action. The iS6059 PCB Inspection Plus stands out as the company’s premier AOI system, combining fast performance with exceptional imaging. Its next-generation 3D camera captures images up to 25 percent faster, ensuring high reliability while driving down long-term production costs.

The iX7059 PCB Inspection XL demonstrates Viscom’s expertise in AXI, delivering precise void analysis and exposing hidden defects in both SMD and THT solder joints, even in challenging assemblies. This innovation is part of the broader iX7059 Series: Viscom’s powerful portfolio of AXI systems: from inspecting components weighing up to 200 kg and measuring 2 meters in length, to achieving resolutions down to 1 micron, this unmatched range underscores Viscom’s commitment to precision at every scale.

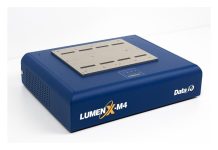

Rounding out the portfolio, the X8011-III brings high-end 2D and 3D X-ray capability to both automated and manual workflows. Its powerful open microfocus X-ray tube and modular design make it especially valuable for high-mix, low-volume production and R&D settings.

By pairing intelligent software with leading-edge inspection equipment, Viscom once again underscores its role as a technology leader. At productronica 2025, the company will show how AI-driven innovation is helping manufacturers simplify operations, reduce costs, and achieve the highest level of quality assurance. True to its guiding principles: “We make technology safe, reliable and sustainable,” Viscom continues to set new standards that help customers secure long-term success in an evolving industry.

Meet the Viscom Team at productronica 2025 to explore how AI is transforming inspection and visit Booth: A2.177 to see how Viscom’s AI solutions can elevate your production.

To learn more, visit www.viscom.com.