Solderstar, a global leader in temperature profiling solutions for soldering processes, is set to unveil its complete vapour phase verification suite at Productronica 2025, Booth A4.220, taking place from 18–21 November at Messe München, Munich, Germany. The new solution combines the VP10 Thermal Profiler and VP Shuttle Verification Fixture, providing manufacturers with a comprehensive approach to process verification, from initial machine qualification through to ongoing production validation of even the most complex boards.

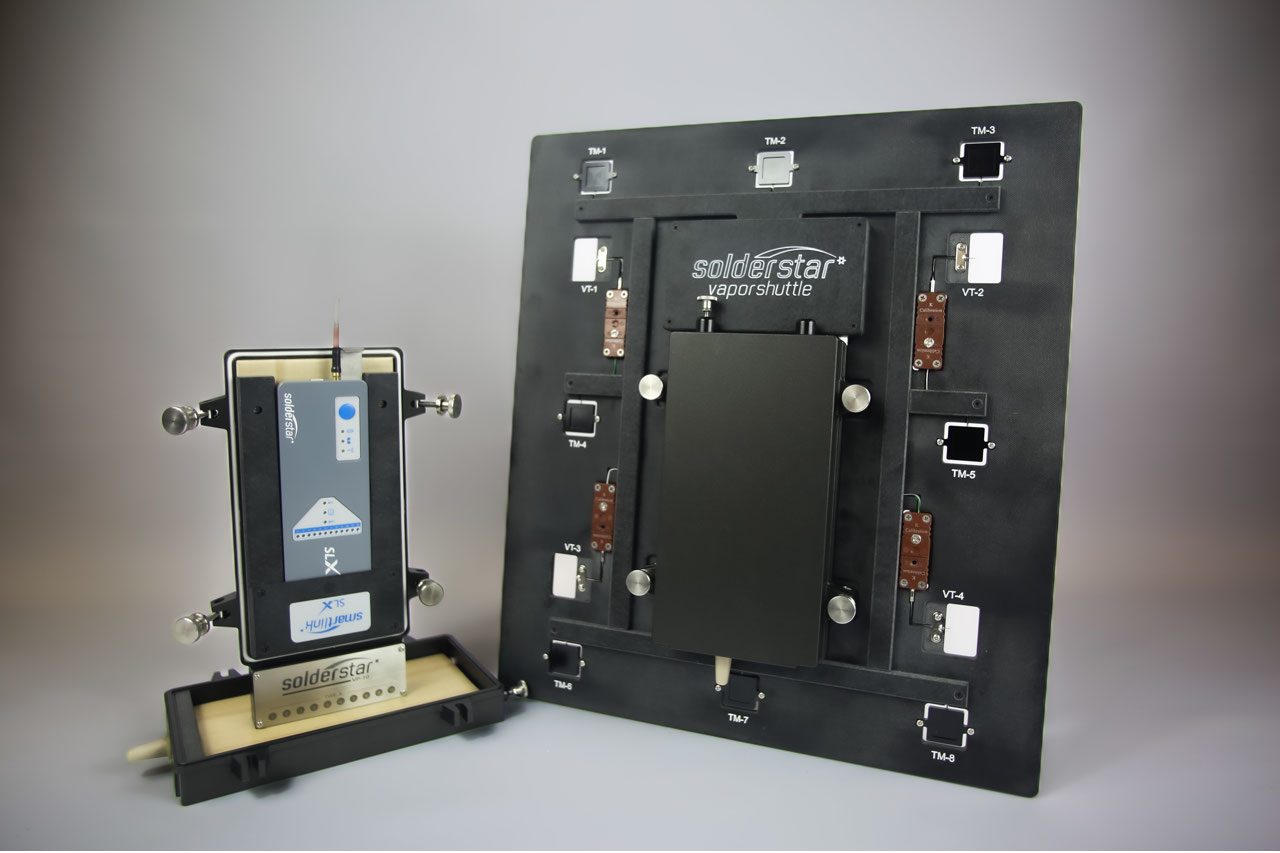

Measuring just 37 mm in height, the VP10 passes through all machines with ease, offering greater flexibility and faster setup times. Its 10 measurement channels provide comprehensive thermal coverage across high-mass components, small passives, and critical board corners, ensuring complete visibility for both initial profiling and subsequent verification runs. This expanded capability reduces blind spots and minimises the number of profiling runs needed to validate complex PCBs.

The VP10 integrates Solderstar’s flagship SLX datalogger, delivering enhanced battery performance and seamless expandability across Solderstar’s range of soldering solutions. Designed for demanding vapour phase processes, it supports vacuum-stage operation and includes a high-temperature connection system, making it suitable for long-duration processes and boards with higher thermal mass, while maintaining precise, repeatable measurements.

Chris Williams, Head of European Sales at Solderstar, said: “The VP10 represents a major step forward in vapour phase profiling and verification. With its low form factor, 10 measurement channels, and SLX datalogger integration, it gives engineers complete visibility of the soldering process. Combined with our VP Verification shuttle, manufacturers now have a complete solution for both machine qualification and product validation, allowing them to reduce rework, optimise throughput, and be confident that even the most complex boards remain within specification every time.”

The VP Shuttle Verification Fixture enables machine qualification and routine verification, testing the vapour phase machine itself rather than individual PCBs. Designed for use in vapour phase machines, it measures 12 separate points to assess temperature uniformity across the oven. Using a standardised plate with thermocouples positioned at strategic, repeatable locations including corners, edges, centre, and top and bottom positions, the VP Shuttle creates a map of the machine’s heating verification across the work zone. This dedicated verification tool is essential for machine acceptance testing during new installations or after service, regular calibration and qualification to maintain process control, and ensuring a consistent thermal environment for any PCB processed in the machine.

Together, the VP10 Thermal Profiler and VP Shuttle Verification Fixture enable the distinction between machine-related inconsistencies and PCB-specific thermal behaviour. This dual approach confirms whether the vapour phase machine heats evenly and verifies whether specific PCBs will solder correctly, giving manufacturers complete confidence in process stability. By identifying whether issues originate from machine performance or board design, manufacturers can meet audit requirements and maintain repeatable results across production.

Combined with the SLX datalogger platform, Solderstar’s complete vapour phase suite offers manufacturers a unified approach to process verification, enabling them to optimise throughput, maintain quality standards, and reduce the risk of defects.

Visitors to Productronica 2025 are invited to see the VP10 Thermal Profiler and VP Shuttle Verification Fixture at Booth A4.220, where the Solderstar team will provide detailed insights and technical guidance.