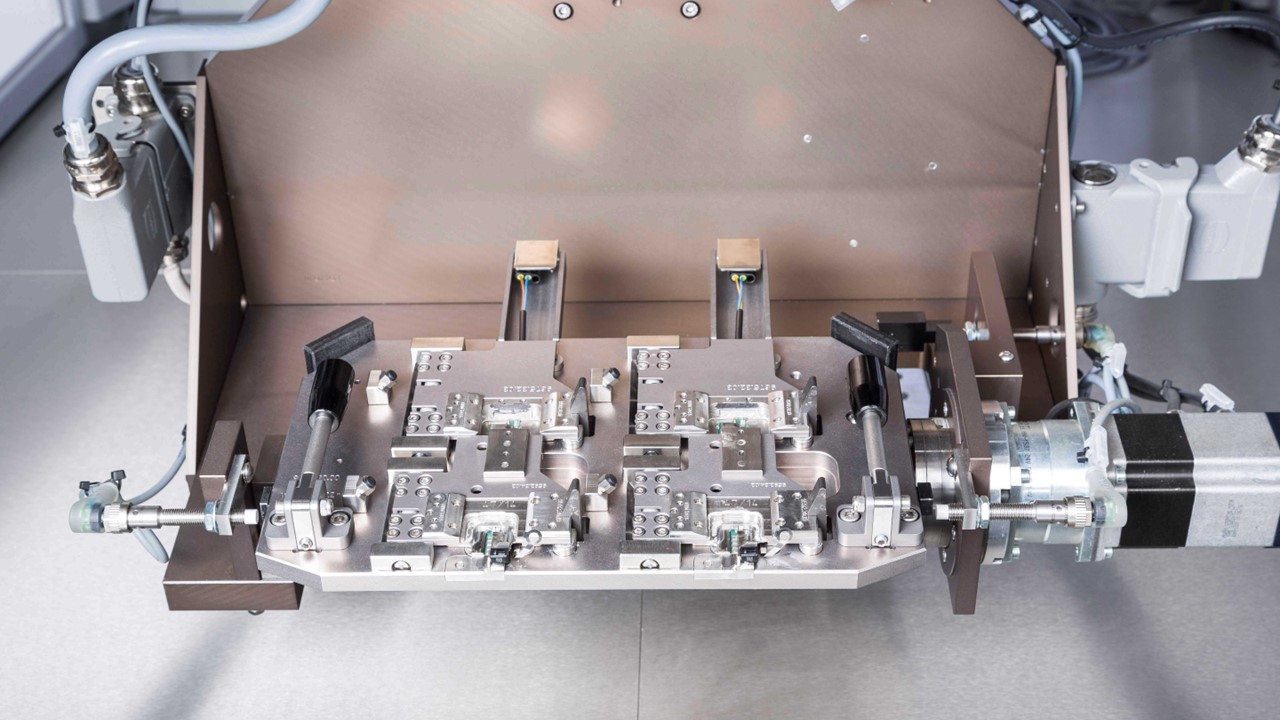

Titanium soldering masks and workpiece carriers play a central role in the selective soldering process. Eutect develops these masks and carrier systems individually according to customer and process-specific requirements. The company combines the highest manufacturing precision with comprehensive material expertise. The specifically developed masks and workpiece carriers stand for repeatable processes, optimized handling, and maximum reliability in electronics manufacturing.

With its new titanium soldering masks, EUTECT offers a cost-effective solution for precise and reliable selective soldering. Thanks to the targeted selection of titanium materials and special surface treatments, the masks have high-quality solder-repellent surfaces with minimal heat sinks. Sensitive components and housings are reliably protected, while the stable yet thin-walled construction ensures optimized solder flow and high solder penetration. Specific, three-dimensional designs reduce the influence of component tolerances, thereby increasing process reliability. This underscores EUTECT’s commitment to providing practical and economical solutions for demanding soldering tasks.

Matthias Fehrenbach, Managing Director of Eutect GmbH: “Our customers benefit from our many years of experience, comprehensive soldering expertise, and design know-how. With our soldering masks and workpiece carriers, we deliver more than just a tool. Through innovative ideas, vision, sophisticated design, and over 30 years of soldering process expertise, we develop solutions between the assembly, soldering process, and automation that measurably increase the quality, reliability, and productivity of selective soldering.”

Individually designed for the assembly, process, and system, the solutions reduce process fluctuations and enable documentable, reproducible results in accordance with IPC and MIL-STD specifications. The targeted guidance of the solder flow protects sensitive components and ensures clean solder joints.

“Based on our decades of experience, our workpiece carriers and soldering masks increase manufacturing reliability and reduce the total cost per solder joint over the life cycle. The reasons for this are less scrap, lower solder consumption, and long service life,” says Fehrenbach. In addition, carriers and masks integrate seamlessly into different automation concepts and non-EUTECT systems with different kinematics.

With customized titanium soldering masks and workpiece carriers tailored precisely to the specific requirements of the assemblies, Eutect creates the basis for a stable, reliable, and efficient soldering process. The masks and carriers are characterized by the use of state-of-the-art, temperature-resistant materials that are also ESD-compliant. Right from the development phase, Fehrenbach’s team considers crucial factors such as thermal mass, heat dissipation, component positioning, and soldering accessibility. The result is a technically sophisticated design that meets the requirements of complex multi-use and double-sided assemblies. At the same time, Eutect attaches great importance to the integration of functional elements such as grip edges, orientation aids, or RFID tags, which facilitate handling and ensure complete traceability.

“Our structured development process is divided into four coordinated steps,” explains Fehrenbach. First, an individual requirements analysis is carried out, in which all component and process requirements such as cycle time, fixing strategy, soldering process, and handling concept are taken into account in detail. This is followed by a thorough design and simulation phase. In this phase, a concept is created using CAD design, supplemented by FEM analyses if necessary, and adapted to the thermal and mechanical conditions. In the subsequent production phase, manufacturing is carried out in accordance with the specifications and adapted to automation, kinematics, and process stations. Finally, process integration follows. Here, the seamless integration of the carriers and masks into the customer’s system or production line is ensured so that the entire process runs smoothly,” says Fehrenbach.

This expertise is based on numerous successfully implemented projects in sectors such as the automotive industry, medical technology, consumer goods industry, and defense technology. The experience gained is continuously integrated into the ongoing development of technologies, supported by modern simulation and measurement technology. Eutect pursues a modular development approach and supports customers from the concept phase through prototyping to series production with customized, economical, and reliable solutions.

Eutect GmbH will be exhibiting at productronica 2025 in Munich, the world’s leading trade fair for electronics development and manufacturing, from November 18 to 21, 2025. At booth 439 in Hall B2, Eutect will be presenting innovative solutions for selective soldering, including its precision titanium soldering masks and workpiece carriers. “Participating in productronica underlines Eutect’s commitment to combining technological excellence with tailor-made customer focus. Visitors to the booth will not only be able to see the soldering processes but also receive individual advice on the wide range of applications in automotive, industrial, medical, and aerospace technology,” explains Fehrenbach.

To learn more, visit