What began in 1989 as a research project between LPKF Laser & Electronics SE and the University of Hannover has developed into one of the most successful product series of the German laser technology company: The ProtoLaser family celebrates its 25th anniversary in 2025. Since the market launch of the first commercial ProtoLaser system in 2000, LPKF has continuously revolutionized laser structuring of printed circuit boards, setting new standards in electronics prototype development.

“The ProtoLaser has fundamentally changed how research institutions and companies develop electronics prototypes,” explains Lars Führmann. “What started 25 years ago as a simple IR laser system for copper processing is today a diverse product family ranging from UV lasers to picosecond systems that can precisely process virtually any material in the electronics industry.”

From Beginnings to High Technology

The success story began in 2000 with the first commercially viable ProtoLaser, which still worked with an external laser source and the ProtoMat 95s system. Just four years later, the ProtoLaser 100 followed as the first system, with an integrated scanner and diode pumped solid state laser. In 2008, the ProtoLaser S was introduced, the first system with scan field stitching for large processing areas. The real breakthrough came in 2012 with the ProtoLaser U3 – the “game changer” featuring the first-ever possible rubout technology with UV laser for large area removal.

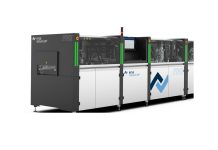

The latest generation comprises four specialized systems: The ProtoLaser U4 with UV laser (over 300 units sold), the ProtoLaser S4 with 532 nm (green) laser with PCB drilling capability (nearly 150 systems deployed), the revolutionary ProtoLaser R4 with 1.5-picosecond pulse length for “cold ablation” without heat-affected zones, and the ProtoLaser H4 for the fastest circuit structuring combined with mechanical processing targeting also thick PCBs and multilayer stacks.

Technology Leap to Atomic Precision

“Our technological development reflects the increasing demands of the electronics industry,” Lars Führmann continues. “While in 2000 we still hoped to cut copper without burning too much substrate, today we work with picosecond pulses at the atomic level through multiphoton effects. This evolution from thermal to virtually thermal-free processes has opened up completely new application fields.”

Today’s ProtoLaser family encompasses a broad material spectrum, ranging from classic FR4 circuit boards to RF substrates, PTFE, polyimide, ceramics, glass, and even graphene and ITO-coated glass. The systems enable structure widths as low as 15 micrometers and processing areas of up to 229 x 305 mm.

Market Leadership Through Continuous Innovation

LPKF invests over 10 percent of revenue in research and development. This consistent innovation strategy has paid off: ProtoLaser systems are today deployed in leading research institutes, universities, and high-tech companies worldwide and are considered the standard for precise PCB prototype development.

“Recognition by renowned research institutions and industrial companies confirms our approach,” emphasizes Lars Führmann. “Our continuous advancement of laser systems, system options, software, and material processing libraries keeps us at the forefront of technology.”

Shaping the Future

For the next 25 years, LPKF sees further innovation potential: “We are already developing the next system generation and exploring new laser technologies. The increasing miniaturization of electronic components and new material requirements will open up additional possibilities for us,” announces Lars Führmann.

LPKF can be found at productronica 2025 in Hall B2 at Stand 305. Many other LPKF technologies will also be presented there: From PCB prototyping, laser depaneling, stencil cutting, laser plastic welding to micromachining of glass substrates and contract manufacturing.

To learn more, visit www.lpkf.com.