Themed ‘Stronger together – Three specialists. One goal: Intelligent solutions for electronics manufacturing,’ cts is exhibiting alongside two strong partners for the first time at this year’s productronica in Munich: AdoptSMT, an experienced supplier of SMT machines and accessories, and FlexLink, an expert in conveyor solutions. From 18 to 21 November, they will be demonstrating a fully integrated solution for SMT production at stand A 3 / 181, in which the interfaces between machines, automation and conveyor technology are perfectly coordinated. The cts Group will be showcasing one of its solutions for the ‘Smart Electronics Factory’: the Smart Warehouse / Mini, a compact and scalable storage system for SMT manufacturing.

Increasing complexity, a shortage of skilled workers, cost pressure – European electronics manufacturers are currently facing major challenges. To proactively overcome these challenges, intelligent solutions are needed that secure processes and enable flexibility. Providing these solutions is the common goal of cts, AdoptSMT and FlexLink. The three companies provide extensive expertise and experience in their respective fields, which they use as partners in joint projects for electronics manufacturing companies: AdoptSMT supplies used and new SMT machines as well as spare parts, consumables and related services. cts offers modular solutions for automating internal material flow in smart factory intralogistics, including scalable storage systems, transfer stations, buffer solutions and AMRs for supplying lines and workstations. FlexLink complements this with modular, scalable PCB transport systems. Together, the three companies are thus able to provide a complete, integrated solution that combines the strengths of all three.

Interfaces between machines, automation and conveyor technology demonstrated live

At their booth at productronica, the three partners cts, AdoptSMT and FlexLink will demonstrate what their collaboration looks like in practice using a complete use case. Visitors can expect a special experience in which the interfaces between machines, automation and conveyor technology are not only explained, but also showcased live from the warehouse to the production line. The case is controlled by AMRs, which retrieve PCB magazines from the warehouse and transport them to the production line. There, they are “processed” by the line and finally picked up again by the AMR at the end and transported back to the warehouse. cts is contributing its compact Smart Warehouse / Mini storage solution to this live demonstration, which was specially developed for optimized material management in production environments with limited space and can therefore also be easily realized at a trade fair stand.

Three specialists – one team

The well-established partnership eliminates typical problems at the interfaces between machines, automation and conveyor technology. Instead of parties that simply refer to the next step and ultimately place the responsibility for coordination and clarity on the customer, the three specialists work as a team. The customer has the choice of appointing one of the companies as the general contractor for their project, thus having a single point of contact, or working with three parties in parallel, with a direct contact for each area of expertise. ‘Because we know each other and collaborate so well as partners, it is easier for the customer – regardless of which path they choose,’ explains Alfred Pammer, VP Sales, Marketing, Product Management at cts.

Smart Warehouse: “fully automated distribution center”

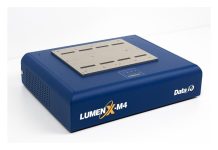

The intelligent smart warehouse systems from cts, which are part of the trade fair presentation, solve a challenge that is common in SMT manufacturing companies: although in theory a perfect one-piece flow makes intermediate storage unnecessary, in practice PCBAs often have to be parked between processes. However, this causes problems: “Not only does it create additional manual labour, which can lead to errors, but it also requires additional production space and results in tedious search processes downstream,” explains Alfred Pammer. Here, the Smart Warehouse comes into play: As a “fully automated distribution center”, it takes over the automatic storage, management and traceability of materials such as KLT containers, trays, PCB magazines and SMT rolls. The key factor here is that the material is provided or collected in line with the production cycle without any delays. Algorithms ensure ideal distribution, while interfaces create transparency: ‘Higher-level ERP or warehouse systems are always up to date on where materials are located and when they entered or left the warehouse,’ explains Alfred Pammer. This ensures that the necessary materials are available at all times, even when production requirements change. This seamless material flow minimizes downtime and increases throughput.

Scalable: Smart warehouses grow with demand

Smart warehouses are tailor-made solutions for the customer. Because the warehouse systems are fully scalable in terms of capacity and functionality, companies can keep their initial investment low by starting with the compact Smart Warehouse / Mini and scale up gradually as demand or requirements change – making them well prepared for future challenges.

To learn more, visit www.group-cts.com/en.