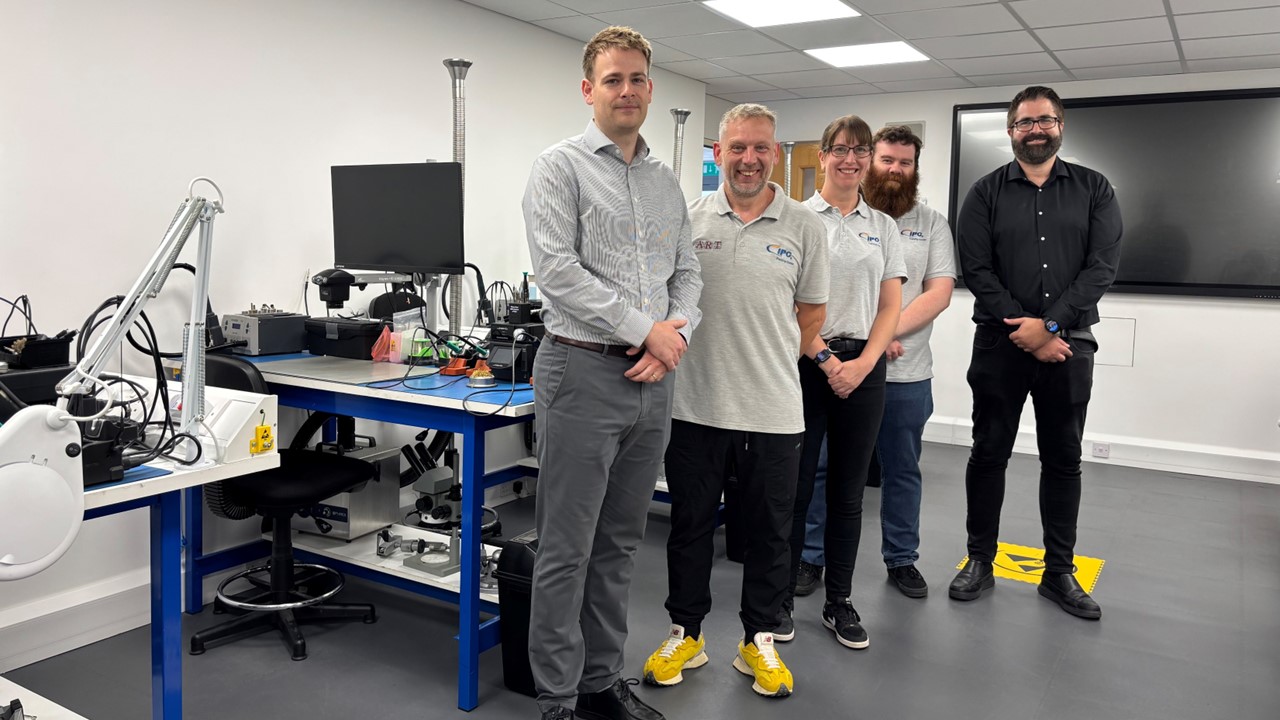

Advanced Rework Technology Ltd. (A.R.T.), a leading independent IPC-accredited training provider, has announced a series of new equipment investments at its state-of-the-art training centre. The additions further enhance the hands-on training experience for delegates, ensuring they work with the same advanced tools and technologies found on modern electronics production floors.

A key addition is the Purex FumeCube system, supplied by long-standing partner Kaisertech Ltd. The extraction unit combines high-grade HEPA and carbon technology to remove 99.997% of particles down to 0.3 microns. The system also features automatic flow control, low-noise operation, and a clear warning system when filters require replacement, ensuring a safe and reliable training environment.

Adam Sibley, Sales and Marketing Director at Kaisertech, said: “We are delighted to be supplying some of the industry’s leading fume extraction and soldering equipment to A.R.T.’s facilities in Witham.

“A.R.T. has consistently invested in creating first-class training environments, ensuring their students gain valuable, hands-on experience with cutting-edge JBC equipment and beyond. At Kaisertech, we are proud to be a trusted partner on this journey providing not only state-of-the-art equipment, but also our technical expertise and ongoing support.”

This latest collaboration with Kaisertech follows additional investments from suppliers across the sector, including ASH Inspex HD digital microscopes for high-quality PCB inspection and Antistat’s ESD protection equipment to strengthen training around electrostatic discharge control. Together, these upgrades ensure that every course at A.R.T. is underpinned by the latest technology, aligning training delivery with current industry standards.

Debbie McDade, Managing Director of A.R.T., said: “For more than 35 years, our focus has been on delivering training that reflects the real-world environments our delegates will return to. By continually investing in new technologies, we ensure our courses provide practical, relevant skills that transfer directly into the workplace. This means our customers can be confident their teams are trained on the same equipment and processes they’ll use every day in production.”

Through strategic investments and partnerships with leading suppliers, A.R.T. continues to strengthen its position as the UK’s most comprehensive provider of IPC and bespoke electronics training.