Two significant milestones in recent days by ESCATEC’s business unit in Bulgaria adds much momentum to the EMS provider’s strategy to nearshore cost-effective and high-quality electronics assembly and plastic moulding services for its customers in the European Union.

ESCATEC Bulgaria (EBG), the Group’s ninth production facility, celebrated its 2nd anniversary in early June with its value proposition generating rapid growth in both capabilities and clientele. The occasion became more memorable by news that the Bulgarian government had awarded its prestigious Investment Class A certification to the company.

EBG’s Investment Class A status followed a comprehensive evaluation process by Bulgaria’s Ministry of Economy and Industry, and acknowledges the company’s compliance with stringent investment and employment criteria. It confers significant benefits to EBG, including expedited administrative procedures, personalised government support, financial incentives for infrastructure development and employee training, and preferential rights to acquire state or municipal property near its operations.

These advantages will facilitate EBG’s goals of expanding production services, onboarding new customers, and growing into ESCATEC’s key hub for electronics assembly and plastic moulding in Europe.

“ESCATEC Bulgaria is a cornerstone of our European strategy. The Class A investment certificate validates our commitment to contribute towards Bulgaria’s economic development and job creation and will further empower us to scale operations in Europe,” said ESCATEC CEO, Charles-Alexandre Albin.

ESCATEC choose to locate EBG in Plovdiv (E.U. member Bulgaria’s second-largest city) in view of its large skilled workforce, large industrial base, and efficient transport links that provide convenient access to the wider European market.

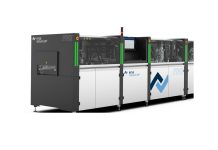

The 4000m² facility has a full complement of advanced machinery (including two SMT lines, reflow ovens, AOI and Pick-and-Place stations, high-speed SPI stations, soldering and x-ray machines, laser markers, Kardex vertical carousel storage, testing stations, and four plastic injection moulding machines) for vertical integration of electronics assembly and plastic moulding.

ESCATEC remains committed to expanding its global production footprint and capabilities to cater to customers that are in the process of bringing new technologies and products to market, noted Albin. The Group already offers a full spectrum of EMS services – from design & development to certification to mass manufacturing and after-sales support – across electronics, mechatronics, machining, MOEMS, box build, and plastic moulding.

Headquartered in Penang Island, Malaysia, ESCATEC’s global production network currently comprises of four facilities in Malaysia; two in the Czech Republic; one in the United Kingdom; a site for advanced electronics in Switzerland, and EBG in Bulgaria. The Group also operates a Design & Development (D&D) Centre in Switzerland and further has strategic partnerships in Croatia and the United States.

Enabling customer success by delivering innovative products that move the world forward