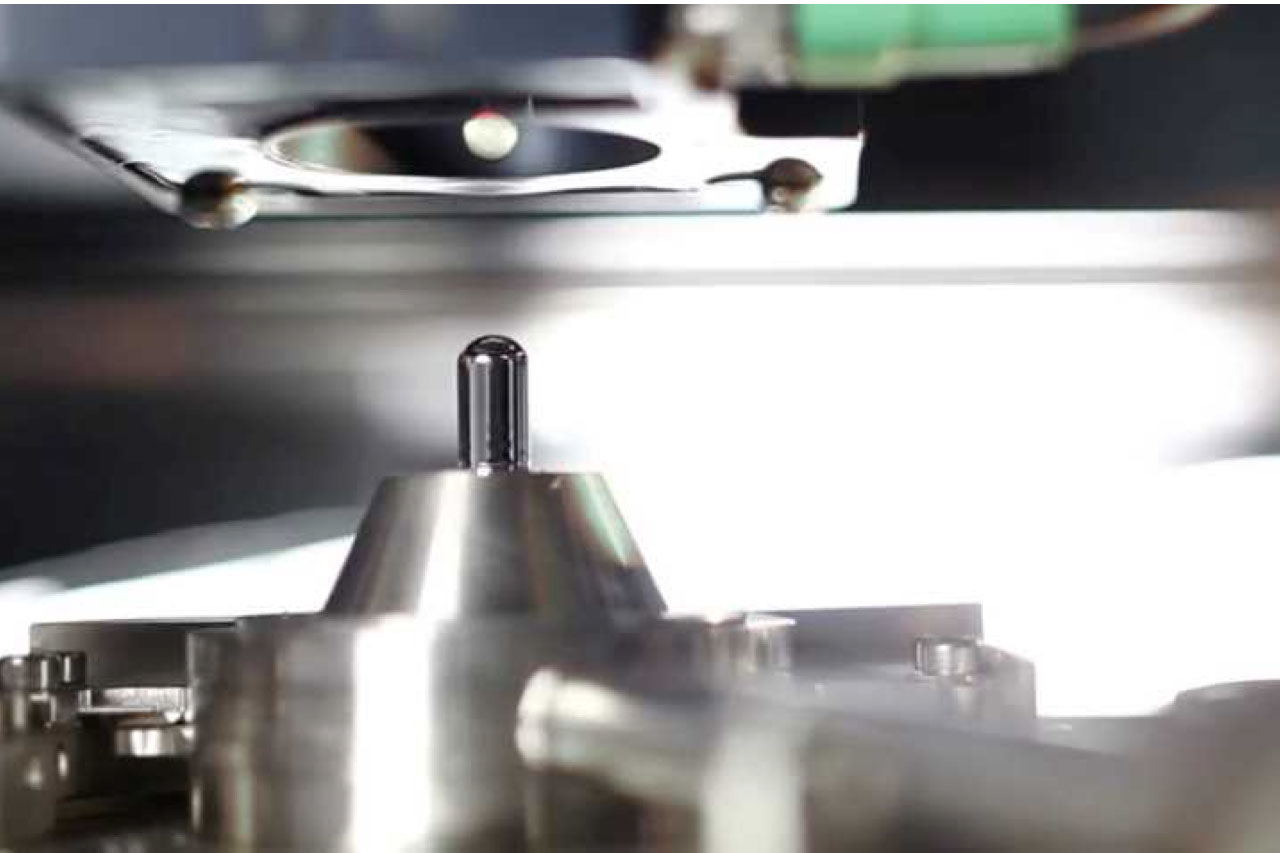

The EO-NOZZLE-PROTECT 1.0 fluid from Emil Otto GmbH is a specially developed protective fluid for soldering nozzles in selective soldering applications. The product forms a film that provides reliable protection against oxidation, dross formation and corrosion, extending the service life of the soldering nozzle without impairing the soldering process. At the same time, the protective film formed by the fluid supports precise and stable solder flow.

“Clean and functional solder nozzles are an important factor for quality and efficiency in the selective soldering process. Dirty or clogged nozzles can significantly impair the dosing of the solder material, resulting in incomplete or faulty solder joints. This can result in unnecessary rework or an increased scrap rate. This risk can be avoided by applying EO-NOZZLE-PROTECT 1.0 to the nozzles,” explains Markus Geßner, Marketing and Sales Manager at Emil Otto GmbH. The protective fluid forms a barrier between the nozzle and the solder, preventing unwanted particles from adhering to the surface. When used regularly, EO-Nozzle-Protect 1.0 saves time and reduces costs since cleaning and maintenance intervals can be reduced.

Since downtimes are reduced and more efficient production processes are achieved, higher productivity and ultimately lower manufacturing costs can be realized. EO-Nozzle Protect 1.0 also ensures an even and smoother flow, resulting in flawless solder joints and improved product quality. “The perfect condition of the nozzles contributes significantly to the efficiency of a system. The machine can only perform at its best when the soldering processes run smoothly,” continues Geßner.

The highly active formula of EO-NOZZLE-PROTECT 1.0 protective fluid forms a colorless and odorless protective film that coats the nozzle outlet. It is easy to apply using the specially developed TIP PEN microliner. This is equipped with a 40 mm long metal dosing needle, which enables precise and clean application. Regular reapplication keeps the protective film intact and ensures consistently high soldering quality.

The protective film is extremely resistant to chemical, physical, and external influences and leaves no residue. It does not stick or resinify, and no pyrolytic deposits are formed. EO-NOZZLE-PROTECT 1.0 is also free of hazardous substances. This means that the fluid is not classified as a hazardous substance, making storage, transport, and use particularly safe and user-friendly. “With EO-NOZZLE-PROTECT 1.0, users benefit from a longer service life for solder nozzles and a trouble-free soldering process,” emphasizes Geßner.

About Emil Otto

Since 1901 “Emil Otto” stands for top quality. As owner-managed company, Emil Otto is committed to the development and manufacturing of high-quality fluxing agents. In particular the fluxing agents for electronics production, strip tinning, cooler construction as well as for galvanizing are used by market leaders at home and abroad.

Over the years, reliable products and a high level of customer care have become the signature. The manufacturing takes place in accordance with the latest standards, the quality- and environmental management system has been certified for many years. Emil Otto responds with high flexibility to customer requests. Special products or product adaptations are developed and implemented in collaboration with system manufacturers and institutes.

Top Picture caption:

High-performance protective fluid for selective soldering nozzles EO-NOZZLE-PROTECT 1.0