I.C.T, a leading provider of intelligent electronics manufacturing solutions, has successfully delivered and installed a fully automated Through-Hole Technology (THT) production line for a prominent Hungarian manufacturer specializing in power controllers. This strategic collaboration underscores I.C.T’s commitment to delivering customized, high-quality solutions that enhance manufacturing capabilities in the electronics sector.

Comprehensive Turnkey Solution

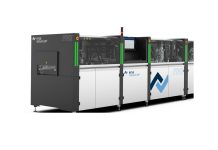

The deployed THT production line encompasses a suite of advanced equipment tailored to meet the customer’s specific production requirements

* Odd Form Insertion Machine: Automates the placement of non-standard components, ensuring precision and consistency.

* Wave Soldering Machine: Facilitates efficient soldering of through-hole components, enhancing joint reliability.

* DIP AOI Inspection Machine: Provides automated optical inspection to detect defects, ensuring product quality.

This comprehensive solution not only streamlines the manufacturing process but also significantly improves production efficiency and product quality.

Collaborative Implementation and Training

The project commenced with in-depth discussions and planning sessions to align the solution with the customer’s operational needs. I.C.T engineering team conducted thorough testing and provided on-site training to ensure seamless integration and operation of the new production line. The installation and commissioning were completed within a week, demonstrating I.C.T’s efficiency and technical expertise.

Customer Feedback and Project Impact

According to the customer’s production manager, the new line has already improved the overall production efficiency by over 30% compared to the previous semi-automated setup. The accuracy and repeatability of the odd-form insertion machine, combined with the stable soldering performance of the wave system and the early defect detection capability of the AOI, have led to a marked reduction in rework and inspection time.

The success of this project marks a significant upgrade to the customer’s manufacturing capacity and lays a solid foundation for future expansion in Europe’s competitive power electronics market.

I.C.T Commitment to THT Automation

While much of the electronics industry continues to focus on SMT (Surface Mount Technology), THT assembly remains essential for specific applications—especially where durability and current-carrying capability are critical. I.C.T continues to invest in the development of smart, automated solutions for THT processes, including selective soldering, robotic odd-form insertion, and integrated inspection technologies.

About I.C.T

I.C.T is a global manufacturer of electronics production equipment. The company offers a full range of solutions for SMT, THT, conformal coating and intelligent factory systems. By combining advanced technology with on-site support and custom engineering, I.C.T helps its customers optimise production, ensure quality, and reduce manufacturing costs.

For more information about I.C.T products and services, please visit : www.smtfactory.com Or Email: smt9@smt11.com.