Seica S.p.A. a global leader in electronic testing solutions, will be present at The Battery Show Europe (Booth 8-C16), and is excited to announce the worldwide premiere of the PILOT BTP, the latest solution in Seica’s Pilot BT series of battery testers.

Ensuring the reliability and safety of EV modules is one of the primary challenges posed be the rapid evolution of the EV market, and the quality and reliability of the electrical connections between the cells of an EV battery are fundamental to its correct performance and safety. The new Pilot BTP is designed specifically for testing these connections in a low-volume prototype or NPI manufacturing scenario, as well as in batteries with cells positioned in non-repetitive geometries. The PILOT BTP is an automated horizontal system with four flying heads, offering true, full-size, parallel EV battery pack testing. It features a test area of 1050 x 865 mm and has been designed to offer the maximum flexibility needed to handle irregular layouts, reaching operating speeds exceeding 600 tests per minute, making it the ideal solution for prototype testing.

Ensuring the reliability and safety of EV modules is one of the primary challenges posed be the rapid evolution of the EV market, and the quality and reliability of the electrical connections between the cells of an EV battery are fundamental to its correct performance and safety. The new Pilot BTP is designed specifically for testing these connections in a low-volume prototype or NPI manufacturing scenario, as well as in batteries with cells positioned in non-repetitive geometries. The PILOT BTP is an automated horizontal system with four flying heads, offering true, full-size, parallel EV battery pack testing. It features a test area of 1050 x 865 mm and has been designed to offer the maximum flexibility needed to handle irregular layouts, reaching operating speeds exceeding 600 tests per minute, making it the ideal solution for prototype testing.

The PILOT BTP adds yet another dimension to Seica’s wide range of flying probe test solutions available to battery manufacturers, which include the Pilot BT and the Pilot BTV, which offer exceptional flexibility and the capacity to accommodate a wide range of battery types—including the largest formats in use today. The Pilot BT is capable of performing precise, parallel Kelvin tests on over 32 cells simultaneously, achieving speeds of nearly 4,800 cells per minute, and its large test area (1200 x 1200 mm) and heavy-duty handling system ensure efficient battery pack management in automated manufacturing lines. For more complex configurations that require multi-sided access, Seica’s Pilot BTV (Vertical Battery Tester) offers automatic three-sided access, making it ideal for “double” battery packs that require bonding tests on both sides as well as test access from the top. Its innovative three-dimensional probing architecture and comprehensive testing capabilities resulted in Seica’s receiving the prestigious Mexico Technology Award in 2024.

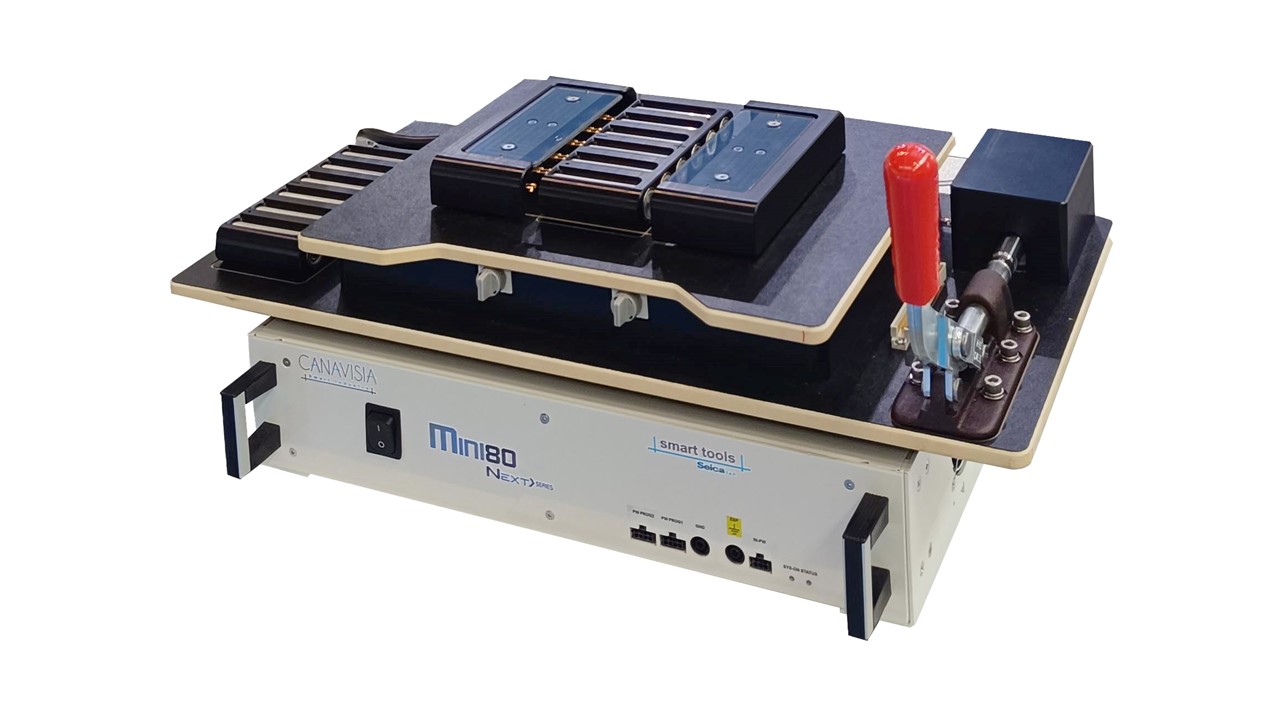

Seica’s MINI80-ACIR tester will also be on display at Booth 8-C16, another innovative test solution developed specifically for the e-mobility sector. This solution was developed to provide a simple and effective means to carry out ACIR and voltage tests, enabling battery pack manufacturers to perform incoming inspection where cells can be tested right in the OEM packaging, as well as production testing to ensure the correct current distribution within the assembled pack. This solution includes Seica’s Mini 80 system, which ensures efficient and precise measurements and provides all of the capabilities to meet test requirements for rigorous internal resistance (IR) testing, including ACIR (Alternating Current Internal Resistance) measurements, typically at 1kHz with a 100mA current, and 4-wire kelvin measurements for each cell The MINI80-ACIR has a maximum expandability of 640 non-multiplexed channels for testing up to 160 cells at a time, and can include a manual fixture or be integrated into an automated system for in-line production testing.

Alongside Seica’s test solutions at Booth 8-C16, visitors can also explore Canavisia’s Industry 5.0 software and hardware solutions. These tools focus on acquiring and digitalizing data from machines, factories, and buildings to support process optimization, predictive maintenance, and intelligent energy management. Accessible onsite, via the web, or from the Cloud, the platform features a Dashboard and App for real-time monitoring and statistical analysis. Fully compatible with major communication protocols and management software, Canavisia’s solutions seamlessly integrate into existing infrastructures.

Visit us at Booth 8-C16 to discover Seica’s cutting-edge test solutions for the EV sector, and to meet with our top experts, ready to help manufacturers tackle electric mobility testing challenges—both from a technical and cost-effective perspective.

To learn more, visit www.seica.com.