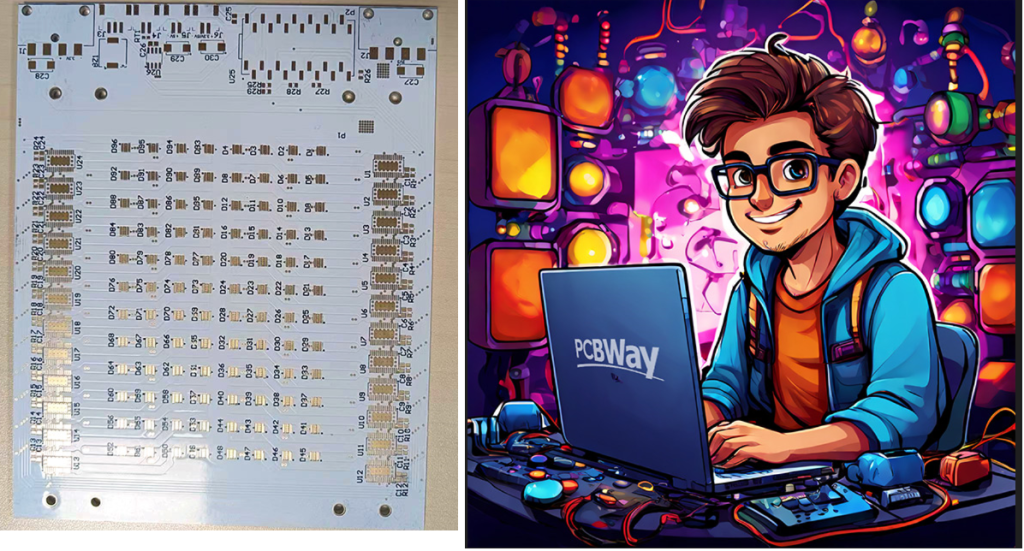

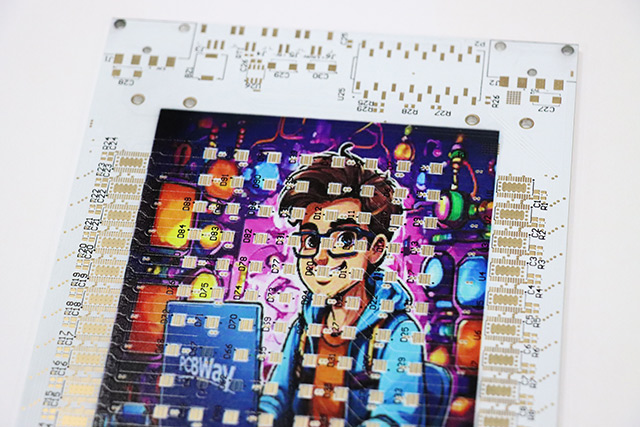

Nowadays, traditional PCB printing technology can no longer meet the aesthetic requirements of modern circuit board production. To better fulfill customers’ design needs, we are pleased to announce that PCBWay has introduced UV printing equipment. This equipment utilizes UV-curable inks to achieve high-quality image printing on various materials, including fiberglass boards, metal substrates, ceramic substrates, flexible boards, and rigid-flex boards.

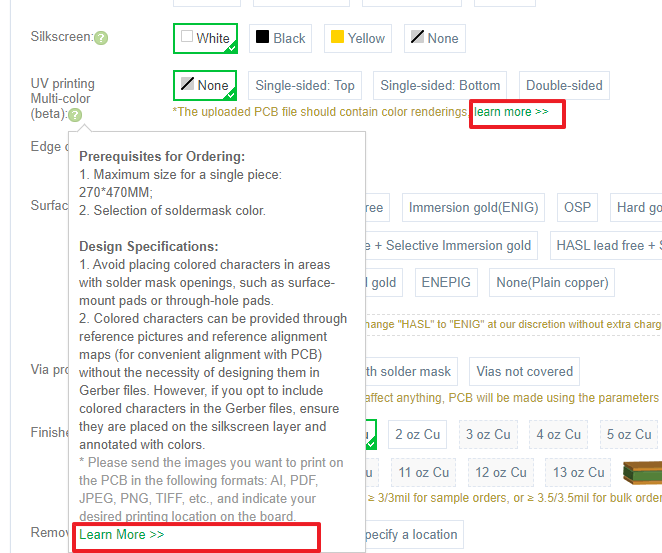

Entrance

www.pcbway.com/orderonline.aspx

Prerequisites for Ordering

- Maximum size for a single piece: 270*470MM;

- Selection of background soldermask color required.

Design Specifications

- Drill holes, traces, soldermasks, and outline designs must comply with specifications.

- Avoid placing colored characters in areas with solder mask openings, such as surface-mount pads or through-hole pads.

- What kind of files should be provided for color printing?

Method One:

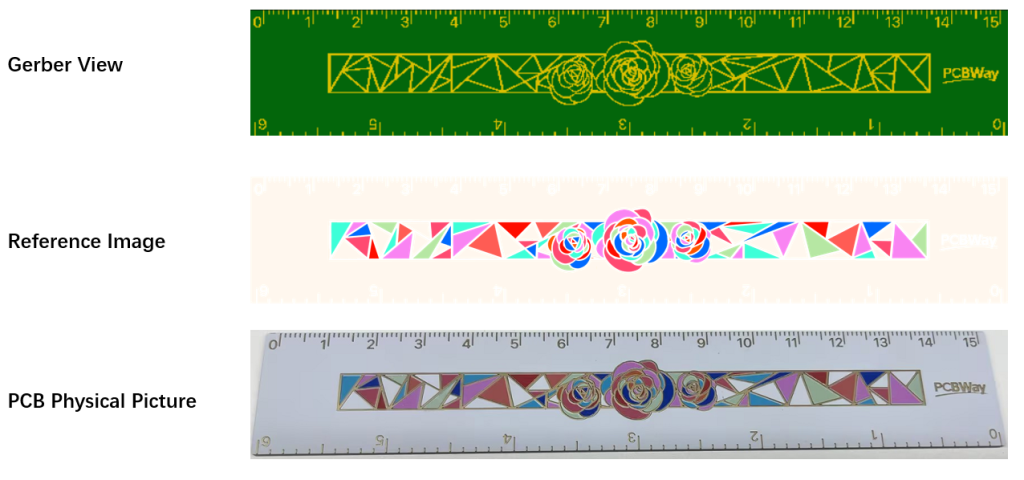

Draw colored characters on the silkscreen layer of the Gerber and provide reference pictures. For example:

Method Two: If you include information about colored silkscreen in the Gerber layer, each individual color must have its own layer. If there is only one layer, we can only print one color. [This method is not recommended].

If you need to print in multiple colors, we recommend using method One and providing us with a reference picture.

4.Please send the images you want to print on the PCB in the following formats: AI, PDF, JPEG, PNG, TIFF, etc., and indicate your desired printing location on the board.

5.If the image contains a QR code, please ensure that the QR code can be accurately scanned and recognized.

Note:

- If you choose UV printing Multi-color, we will use matte UV color printing by default.

- When designing the colored characters on the bottom layer, be careful not to design the colored characters as mirrored inverses. (The process of color printing is different from that of standard PCB silkscreen printing. When printing colorful characters on the bottom layer, they are printed with the bottom layer of the PCB facing up.)

- For situations where the entire top or bottom side requires full-color printing, regardless of the solder mask color you choose, we will use a white solder mask on the full-color printed side and then proceed with the color printing. This is for a better printing effect.

- Please upload the print image, positioning image, and Gerber in one compressed file.

By providing a clear positioning image and necessary instructions, you can assist PCBWay in accurately determining and achieving the desired printing position.

Matte UV Color Printing vs. Glossy UV Color Printing

- Matte ink does not increase the overall thickness, and the PCB’s appearance looks smooth.

- Glossy ink increases the overall thickness and may affect the soldering of component pads. The appearance is beautiful but uneven.

Features

- Adopting UV-LED lamp curing, which enables instant drying, can significantly enhances production efficiency.

- UV printing technology employs UV-curable inks, ensuring firm and clear printing information resistant to fading, thus enhancing product identification and aesthetics.

- The normal print survives SMT reflow.

- UV printing technology can present images in various colors and styles, meeting customers’ personalized requirements. Professional industrial-grade UV printers support high-precision printing, delivering exquisite results whether on flat panels or rolled materials.

- Unlike traditional printing methods, UV printing does not produce volatile organic compounds during the production process, ensuring air quality in the production workshop and providing employees with a safer and healthier working environment.

FAQ on UV Printing:

- Can the UV printed surface be cleaned with water?

Yes, it can be cleaned with water.

- Can the UV printed surface be cleaned with alcohol?

It is more difficult to clean after being exposed to alcohol and baked (currently, the board undergoes a short baking process after UV printing). However, with increased contact time with alcohol and vigorous scrubbing, it can be removed. This also depends on whether the UV is on the copper surface or the solder mask surface.

- How hard is the UV printed surface (sensitivity to scratches)?

The UV surface is not sensitive to scratches. However, compared to the solder mask, it is less scratch-resistant because UV printing is ink that is sprayed on and is relatively thin.

Welcome to give it a try if you’re interested! Besides, PCBWay will continue to enhance its manufacturing capabilities to bring more choices and personalized services to customers in the future.

To learn more, visit www.pcbway.com.