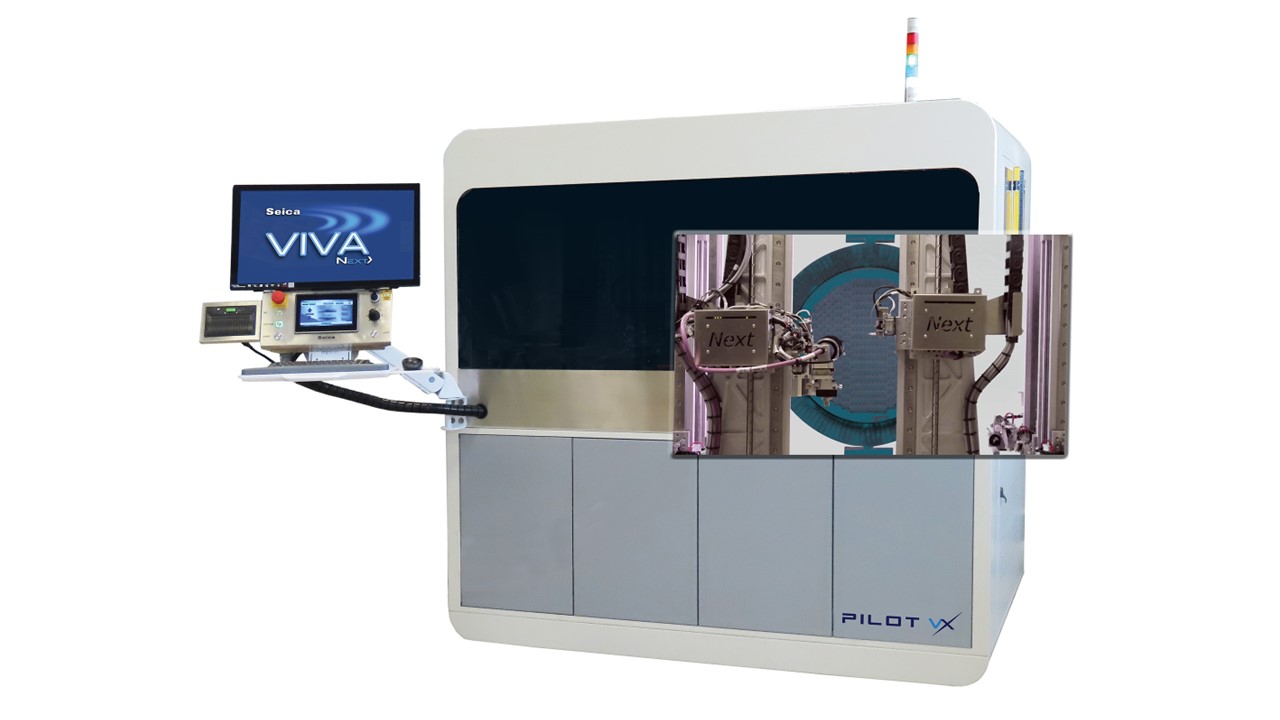

With many years of experience in probe card testing, Seica has designed and developed the Pilot VX HR XL platform, a flying probe system that offers a comprehensive, turnkey solution for testing probe cards that will be on display premier at Semicon Europe, Hall C2 Booth 160.

![]() A leading provider of Flying Probe technology, Seica’s newest line of testers brings with it key advances and features required in the semiconductor market.

A leading provider of Flying Probe technology, Seica’s newest line of testers brings with it key advances and features required in the semiconductor market.

This vertical system combines hardware and software in a single platform to perform three different types of tests: testing individual MLO and PCB boards before assembly, in-circuit (ICT) and functional testing of PCBs after assembly, and final testing of the probe card, which involves combining the PCB with the MLO. The final test includes an ICT that checks the integrity of every connection between the MLO and the PCB interface. The Pilot VX HR XL system automatically generates a specific test, taking into account the resistance of each path, which may vary due to differences in network lengths or the presence of components on the MLO. The integrated measurement system, leveraging DSP technology, can communicate in real-time with the central unit, enabling highly accurate and precise capacitive, resistive, and inductive measurements at impressive speeds. This innovative system of stimuli and measurements is directly installed on mobile probes, allowing for “ultra-fast capacitive” testing to optimize testing times.

Equipped with two high-resolution cameras, the system has a front camera with over 12 megapixels and an optical resolution of 0.9 µm, as well as a rear camera with a resolution of 10 µm, both featuring motorized focus. Additionally, there are two cameras to verify the contact position of the standard probes.

Traditional flying probe test area sizes can be a limiting factor, so much so, the probe cards don’t even fit in the test area. To accommodate this market requirement, Seica developed also a XL version to accommodate boards with sizes up to 810 x 675 mm. However, the area of the board may not be the only limiting factor, as board thickness and weight are also a concern. Board construction easily exceeds 50 layers in most cases, and the boards will not meet traditional thicknesses. The Seica XL structure can optionally accommodate even larger thickness up to 12 mm.

The Pilot VX HR system, like all Seica solutions, integrates the VIVA software platform. This includes automatic generation of BBT and ICT test programs by importing CAD/CAM data in IPC-D356A (CAM350) and ODB++ formats, and provides comprehensive data output for thorough traceability of the tests performed.

The Pilot VX HR can also be managed remotely via a web-based control panel, allowing operations that would typically require the operator to be present at the machine. This enables centralized control and faster setup and monitoring of the production line. The system is integrable with the company’s MES, thereby complying with Industry 4.0 standards.

Come visit us at Booth A1-445 and Booth A3-335 to see how our innovation can help accelerate yours!

For more information, visit www.seica.com.