Yamaha Motor Robotics FA Section showcased new collaborations with system integrators at Motek 2024 in Stuttgart, automating industrial processes across the production lifecycle including assembly, sorting, and testing.

“We continue to grow our portfolio of projects that embed Yamaha robots to provide fast and repeatable picking and placing or lifting and moving, with highly accurate positioning,” said Tatsuro Katakura, FA Sales Manager, Yamaha Motor Europe Robotics Business, Factory Automation Section. “These examples show how we can help companies serving sectors such as consumer electronics, automotive components, textiles, pharmaceuticals, and food production to boost production quality and raise productivity.”

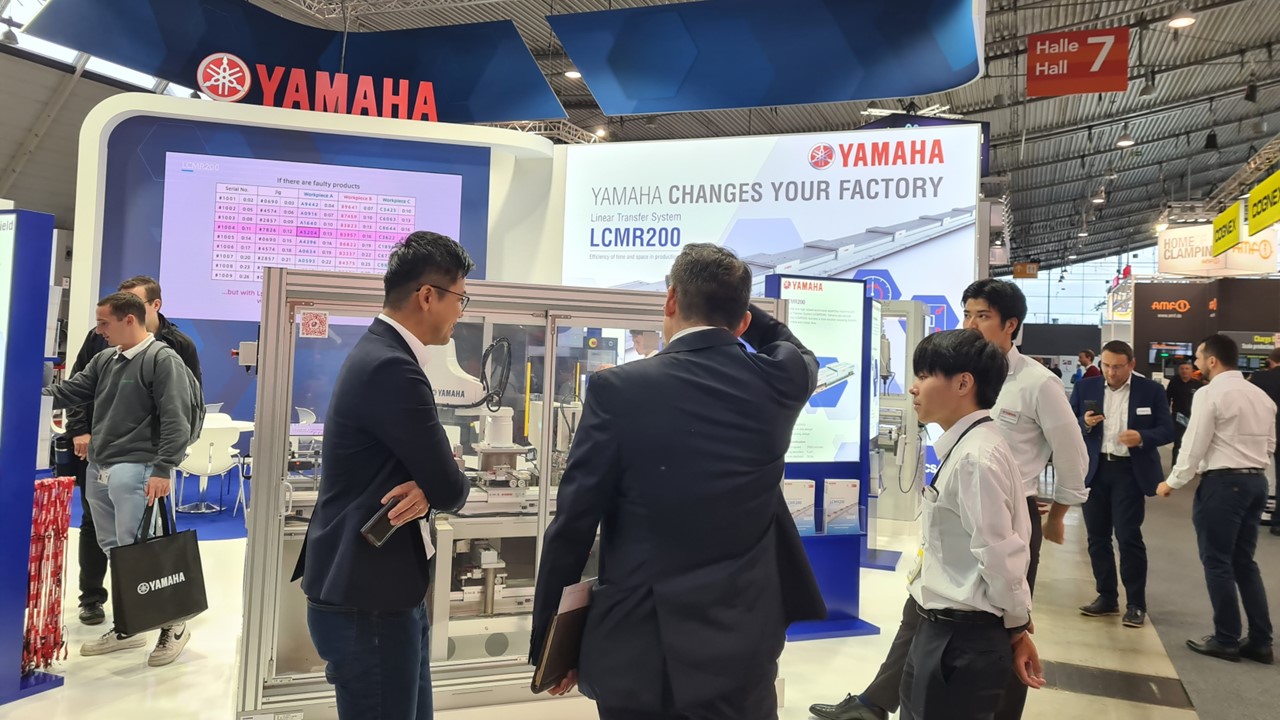

Yamaha’s booth demonstrations at Motek showed how SCARA and cartesian robots add value to custom automation designed for repetitive processes like punching, sorting, and testing.

The robotic punching machine configures electrical connectors at high speed, leveraging the compact YK-XE SCARA’s ability to quickly change tooling, position each connector quickly and accurately, and inspect after punching using the integrated vision system.

The sorting machine contains Yamaha’s YK-XG series SCARA with ultra-precise and reliable beltless motion to quickly palletise small components by accurately picking from detected positions.

In addition, the team presented a versatile automatic PCB tester that integrates Yamaha’s XY-X cartesian robot to provide flexible positioning for in-circuit tests, functional tests, and programming.

The demonstration showing end-of-line handling for EV batteries, featuring the larger YK1200X SCARA, showing how the combination of high payload capacity and optimised internal balance to manage inertia enables lifting and moving heavy items at speed, and final positioning with sub-millimetre accuracy.

A further showcase featuring Yamaha’s LCMR200 flexible transport system gave insights into how enterprises can reimagine conventional production lines to raise output, enhance uptime, ease scalability, and utilise factory floorspace efficiently. The LCMR200’s horizontal and vertical circulation units, and the traversing unit that adds further flexibility, are ultra-reliable, simplify product traceability, and permit production-line maintenance with non-stop productivity.

“Motek attracted visitors from a wide range of industries and many came with intriguing automation challenges, making for a high-quality audience,” added Tatsuro Katakura. “As always, there were many opportunities to explain how our robots can help enterprises to become more competitive, agile, and futureproof. We look forward to strengthening the connections we made with potential new customers.”

About Yamaha Robotics FA Section

Yamaha Factory Automation Section (FA Section), a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, is focused on delivering flexible, high-accuracy industrial robots for precision automation challenges.

With its roots in the introduction of robot technology to Yamaha motorcycle assembly activities, the division has over 40 years’ experience solving automation challenges from factory-scale to micron-level. Yamaha’s industrial robots are now trusted by leading corporations worldwide, in activities as diverse as semiconductor fabrication and assembling electronic products, domestic appliances, automotive components, and large liquid-crystal panels.

Yamaha Motor FA Section offers a unified range of solutions for robotic assembly, including single-axis robots, SCARA, cartesian, and articulated robots. Innovations such as the LCMR200 linear conveyor module; a smoother, space-saving and more versatile successor to conventional belt and roller conveyors continue to set the pace in factory automation. Core robotic technologies as well as key components and complete robot systems are all produced in-house, ensuring consistent quality and control over lead-times.

Headquartered in Neuss, Germany, Yamaha FA Section serves customers in all Europe.

#DiscoverYamahaRobotics