Discover PDR’s state-of-the-art technology that has positioned them as a global leader in SMD BGA rework stations.

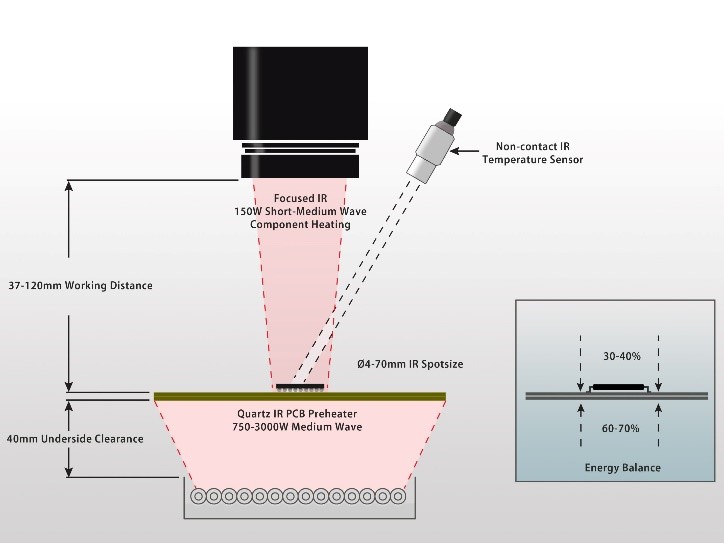

PDR Heating Technology Utilizing Focused Infrared

Achieving maximum yield in rework processes requires adherence to the same principles as with reflow ovens. PDR accomplishes this with a combination of Focused IR and Medium Wave IR: 30-40% from the top and 60-70% from below. PDR’s Focused Infrared technology is the only visible heating solution on the market, eliminating guesswork and providing unbeatable, repeatable temperature profiles with no time lag. Quartz Medium IR Heaters preheat the board, preventing delamination and thermal shock to components.

With Closed-Loop Control, PDR’s system measures and controls component and board temperatures independently, ensuring the best temperature profiles. PDR’s Thermo-Active software automatically adjusts the power to follow the temperature profile accurately, delivering the most precise and repeatable results in practice.

With Closed-Loop Control, PDR’s system measures and controls component and board temperatures independently, ensuring the best temperature profiles. PDR’s Thermo-Active software automatically adjusts the power to follow the temperature profile accurately, delivering the most precise and repeatable results in practice.

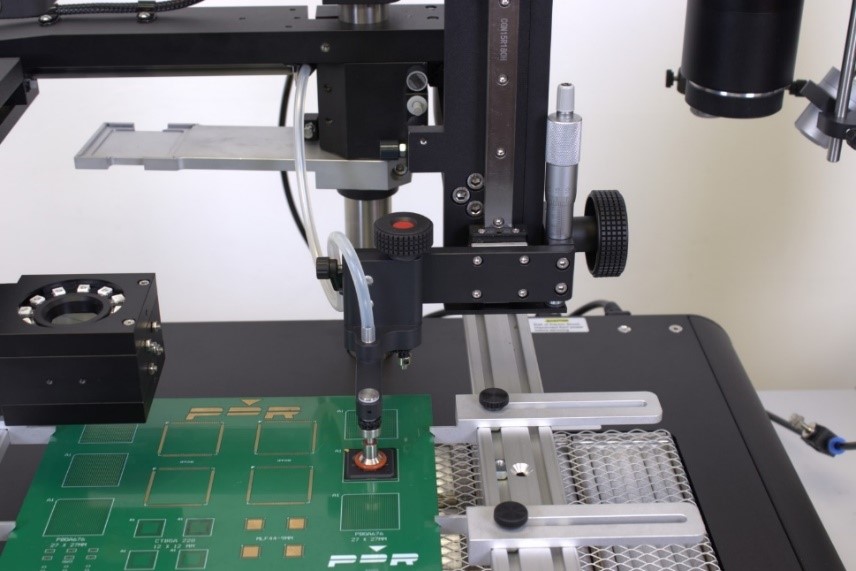

PDR Placement Technology

PDR Pick and Place is simple to use on any component, with no programming required, and no delay, allowing any operator to achieve consistent quality. The system’s Prism allows simultaneous viewing of components and pads, with independent prism lighting and different colors for various boards. A gig-e camera provides the best definition and quality with optical and digital zoom capabilities. Additionally, the software supports video and image frame grabbing.

PDR Pick and Place is simple to use on any component, with no programming required, and no delay, allowing any operator to achieve consistent quality. The system’s Prism allows simultaneous viewing of components and pads, with independent prism lighting and different colors for various boards. A gig-e camera provides the best definition and quality with optical and digital zoom capabilities. Additionally, the software supports video and image frame grabbing.

Learn more about PDR’s industry-leading rework stations by contacting us at sales@pdr-rework.com or visiting www.pdr-rework.com.