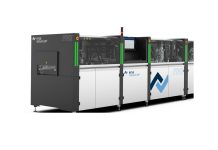

Brillopak has completed a 12-month re-engineering programme to streamline the size and price of their most popular case/crate packing systems; the UniPAKer, PunnetPAKer and TrayPAKer. At PPMA stand C62, Brillopak will reveal next generation systems – the UniPAKer II, PunnetPAKer II and TrayPAKer II – which are 25% cheaper and smaller than their predecessors and have a build time of less than 8 weeks, but still maintain the same build quality, speed, consistency and repeatable pack presentation in crates and cases.

“Last year’s PPMA 2022 show highlighted the importance to us to get back to basics. We are finding that customers don’t want more for their money; they simply want to spend less on easy to integrate machinery,” comments Brillopak’s Technical Director Peter Newman. “We spent 12 months re-engineering the most popular food and FMCG case/crate packers in our portfolio by combining old and new technologies to reduce their price and footprint. I’m delighted to announce that the price of our PunnetPAKer II is reduced by 25% starting at £100k for a system which we can build in less than 8 weeks,” adds Peter.

Brillopak’s re-engineering programme has been carried out by its full-time in-house R&D department focusing on using the best of established and new technologies, removing surplus cables and panels to reduce costs, simplified frame structure (not over engineered), streamlining components/controls and making parts common across their portfolio. “We’d like to thank our trusted partners and those who continue to collaborate with our re-engineering programme and adventure to make the best pick, place and packing systems affordable to all: Omron, Norgren, Wenglor, SLPlastics, Underwoods, Vmeca,” concludes Peter.

Brillopak welcomes all food, chemical, FMCG and cosmetic manufacturers/packing factories to discuss their pick, place, pack end-of-line needs at the Brillopak stand C62, PPMA show this week.

To learn more, visit www.brillopak.co.uk.