Austin American Technology (AAT) will exhibit at the 2026 APEX EXPO, March 17–19 at the Anaheim Convention Center in Anaheim, California. Visitors can find AAT in Booth 638, where the company will be running live demonstrations of the new Typhoon Super T8 inline cleaner alongside its well-known X-30A fully automatic stencil, PCB, and misprint cleaning system.

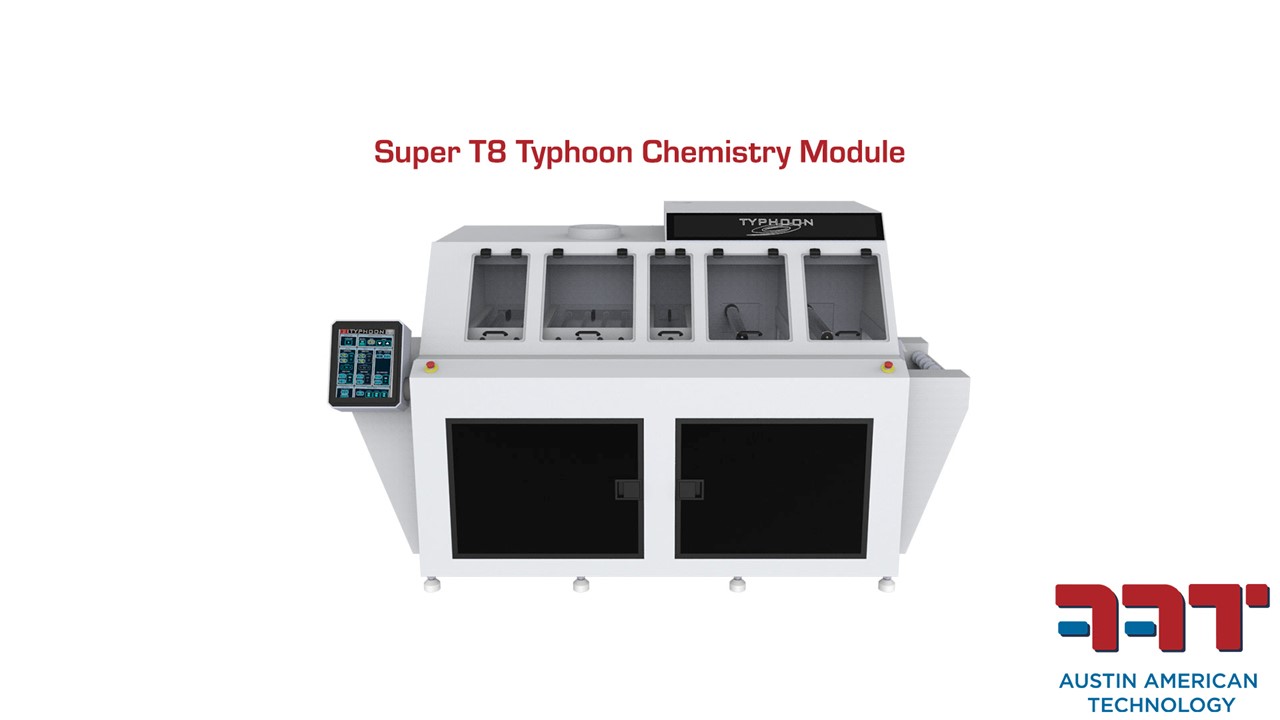

The Typhoon Super T8 is the newest addition to AAT’s Typhoon inline cleaner family and builds on the original, award-winning T8 platform. Designed specifically for chemical cleaning applications, the Super T8 uses a dual-wash configuration to deliver consistent impingement across the full width of the conveyor. It also features the largest isolation section currently available in an inline cleaner—while still maintaining a compact footprint on the production floor.

A key advantage of the Super T8 is its modular design. Manufacturers running an existing water-soluble inline cleaner can place the Super T8 ahead of it, creating a single line capable of both chemical and aqueous cleaning. This setup is particularly useful for contract manufacturers processing a wide mix of products, allowing chemistry to be used only when necessary and helping reduce both chemical consumption and run time.

The Super T8 runs on a Linux-based control platform and supports CFX, MES, and smart factory connectivity. A standard 24-inch usable belt width accommodates a broad range of board sizes, while dual high-pressure wash pumps and carefully positioned spray bars deliver uniform cleaning performance across the conveyor. The system is commonly selected for applications in defense, aerospace, and microelectronics, where cleaning consistency is critical as components continue to shrink.

Also on display at Booth 638 will be AAT’s X-30A Fully Automatic Stencil, PCB, and Misprint Cleaner, a staple in electronics manufacturing facilities worldwide. The X-30A was the industry’s first cleaning system to fully integrate SMART I/O Link devices and is designed to handle everything from stencils and misprints to populated circuit boards and production tooling.

The vertical-format batch system supports aqueous, semi-aqueous, alcohol-based, and hybrid solvents, giving manufacturers flexibility across a wide range of cleaning processes. Patented rotational spray technology creates shifting zones of force to improve residue removal, while fully automated wash, rinse, and dry cycles eliminate manual handling. The X-30A also offers selectable open- or closed-loop operation, integrated filtration, and a compact footprint with a low-profile automated lift to make efficient use of floor space.

To see the Typhoon Super T8 and X-30A in action and speak with AAT’s cleaning specialists, visit Austin American Technology at Booth 638 during IPC APEX EXPO 2026.

For more information about Austin American Technology, please visit www.aat-corp.com.