PEMTRON, an inspection equipment developer and supplier, will exhibit at the 2026 APEX EXPO, taking place March 17–19, 2026, at the Anaheim Convention Center in Anaheim, California. Visitors are invited to stop by Booth 946 to see PEMTRON’s latest inspection and measurement solutions designed to support higher speeds, greater accuracy, and increased automation across electronics manufacturing lines.

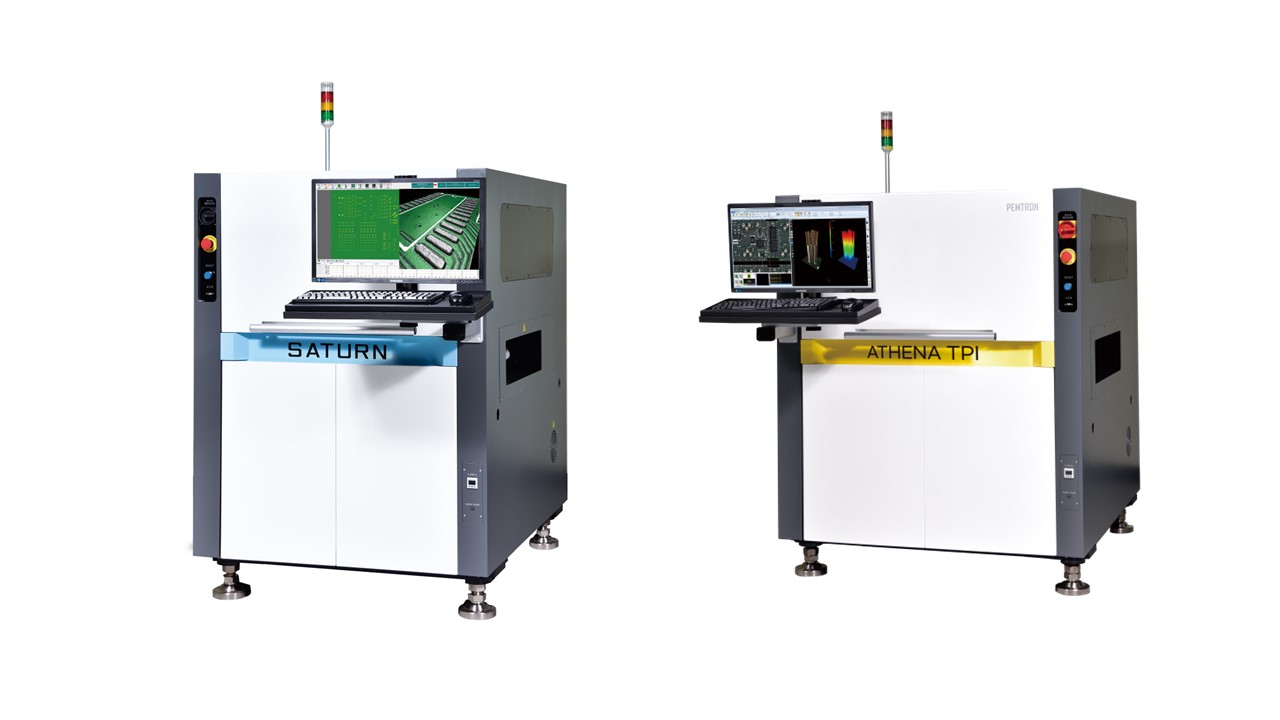

On display will be PEMTRON’s ATHENA, SATURN ULTRA, 8800CI, Mercury 6, and TWIN systems, representing a broad range of technologies spanning solder paste inspection, AOI, conformal coating inspection, inventory management, and double-sided inspection.

A key highlight will be the SATURN ULTRA, PEMTRON’s upgraded, ultra-high-speed SPI system. Building on the proven SATURN platform, SATURN ULTRA delivers significantly enhanced inspection speed compared to the previous SATURN system, making it ideal for manufacturers operating fast, high-volume production lines. It is designed to maintain precise control of solder paste volume and height without sacrificing throughput, while providing realistic solder paste images and consistent measurement performance even in demanding production environments.

PEMTRON will also showcase the ATHENA 3D AOI System, which incorporates AI-based inspection capabilities such as automatic judgment, auto-teaching, and OCR. ATHENA’s 12-way projection design reduces shadowing and supports accurate 3D measurement, while simultaneous 2D and 3D inspection enables detailed analysis at resolutions down to 10 microns. An optional 12MP camera and three-stage conveyor help maximize inspection speed and throughput.

For conformal coating inspection, PEMTRON will feature the TROI 8800 CI Series, which combines AI-driven inspection with advanced hardware design. The system’s deep learning engine is trained to identify coating-related defects such as cracks, voids, and internal bubbles with a high degree of consistency. Automated teaching functions reduce setup time and support faster changeovers, making the 8800 CI well suited for high-mix production environments.

Also on display will be the MERCURY 6 Automated X-ray SMD Counter, designed to improve inventory accuracy and production efficiency. The system uses AI-based counting to deliver fast, reliable results and can accommodate up to four 7-inch reels or a single 17-inch reel. With ERP integration, barcode monitoring, and label printing, MERCURY 6 helps manufacturers reduce manual counting errors and maintain tighter control over component inventory.

Rounding out PEMTRON’s APEX lineup is the EAGLE 3D 8800 TWIN, a top-and-bottom double-sided 3D AOI system. The TWIN platform enables simultaneous inspection of both sides of an assembly, providing complete coverage for double-sided boards. An upgraded inspection head improves 3D image stability and accuracy, helping manufacturers streamline double-sided AOI processes while improving overall inspection efficiency.

To learn more about PEMTRON’s inspection and measurement solutions and see these systems in action, visit PEMTRON at Booth 946 during the 2026 APEX EXPO.

For more information about PEMTRON, please visit www.pemtron.com.