Kurtz Ersa Inc., a leading supplier of electronics production equipment, will make a major February presence across the SMTA calendar, participating in three regional tabletop events to discuss its most recent process innovations for electronics manufacturing. The company will present a lineup of new and updated platforms, engage with customers and industry peers, and demonstrate equipment suitable for high-mix, high-reliability applications.

Kurtz Ersa will be exhibiting at the following SMTA events:

- SMTA Houston

February 10, 2026 — Stafford Centre, Stafford, TX - SMTA Austin

February 12, 2026 — Travis County Exposition Center, Austin, TX - SMTA Wafer-Level Packaging Symposium

February 17-19, 2026 — Hyatt Regency San Francisco Airport, Burlingame, CA

At each tabletop event, Kurtz Ersa representatives will be available to discuss equipment features, share application insights, and answer questions about process requirements and optimization strategies.

Featured Technologies

Highlights of the exhibits include both new introductions and established platforms that represent the company’s latest advancements in reflow, selective soldering, and hand soldering systems:

- HOTFLOW THREE Reflow Oven — Equipped with Ersa’s SCPU® (Smart Convection Power Unit), HOTFLOW THREE delivers stable thermal profiles with precise control and significantly reduced nitrogen consumption, helping manufacturers balance process performance with efficiency.

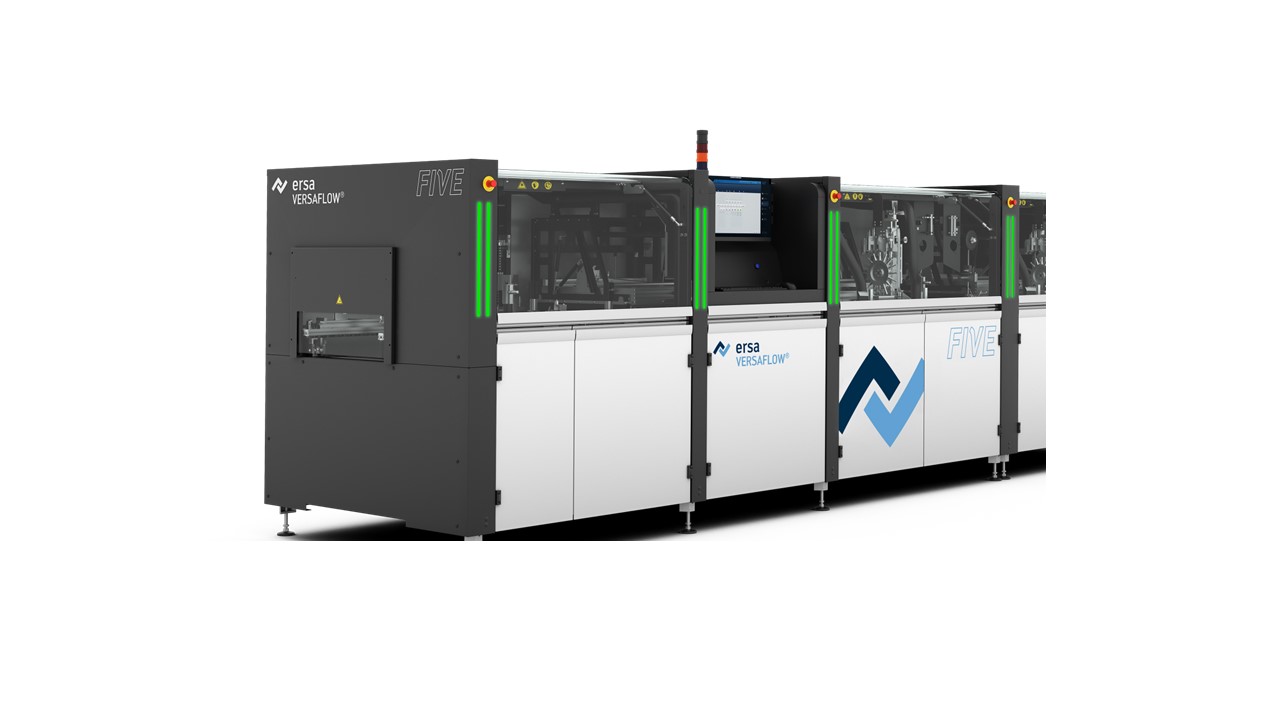

- VERSAFLOW SERIES Selective Soldering Platforms

• VERSAFLOW FIVE (new) — Designed for higher output with reduced line complexity, the VERSAFLOW FIVE features the VERSAFLEX 2.0 solder module, enabling two PCBs to be processed independently within one machine.

• VERSAFLOW 4 CORE Edition (new) — Offers a core-focused selective soldering solution for efficient processing in compact form.

• VERSAFLOW ONE — A flexible selective soldering system suitable for diverse assembly requirements. - POWERFLOW SERIES

• POWERFLOW FIVE (new) — A versatile soldering platform integrating power and process control for reliable selective soldering performance.

• POWERFLOW ONE — Combines ease of use with robust capability for a broad range of production needs. - HR 600 XL Rework System — Now equipped with a new heating head optimized for larger components and high-density assemblies, the HR 600 XL supports precise, controlled rework on BGAs, QFNs, connectors, and other complex packages.

- i-CON TRACE Soldering Station — Newly CFX-certified and ready for connected factory environments, the i-CON TRACE provides built-in traceability, IoT connectivity, and detailed insight into hand soldering processes to support quality assurance, process documentation, and compliance.

“Kurtz Ersa is proud to take part in three SMTA events this February,” said Ernie Grice, Vice President Sales at Kurtz Ersa, Inc. “These regional tabletop shows give us the opportunity to connect directly with customers and demonstrate how our newest technologies — from adaptive reflow to advanced selective soldering and networked hand soldering — can help manufacturers meet both current and future challenges.”

For more information about Kurtz Ersa’s solutions and regional event participation,