BEST Inc., a leader in electronic component and PCB services, is pleased to announce they offer a complete range of rework and repair services to reliably rework and repair circuit boards with mirrored ball grid arrays (BGA) devices mounted on both side of double-sided printed circuit boards.

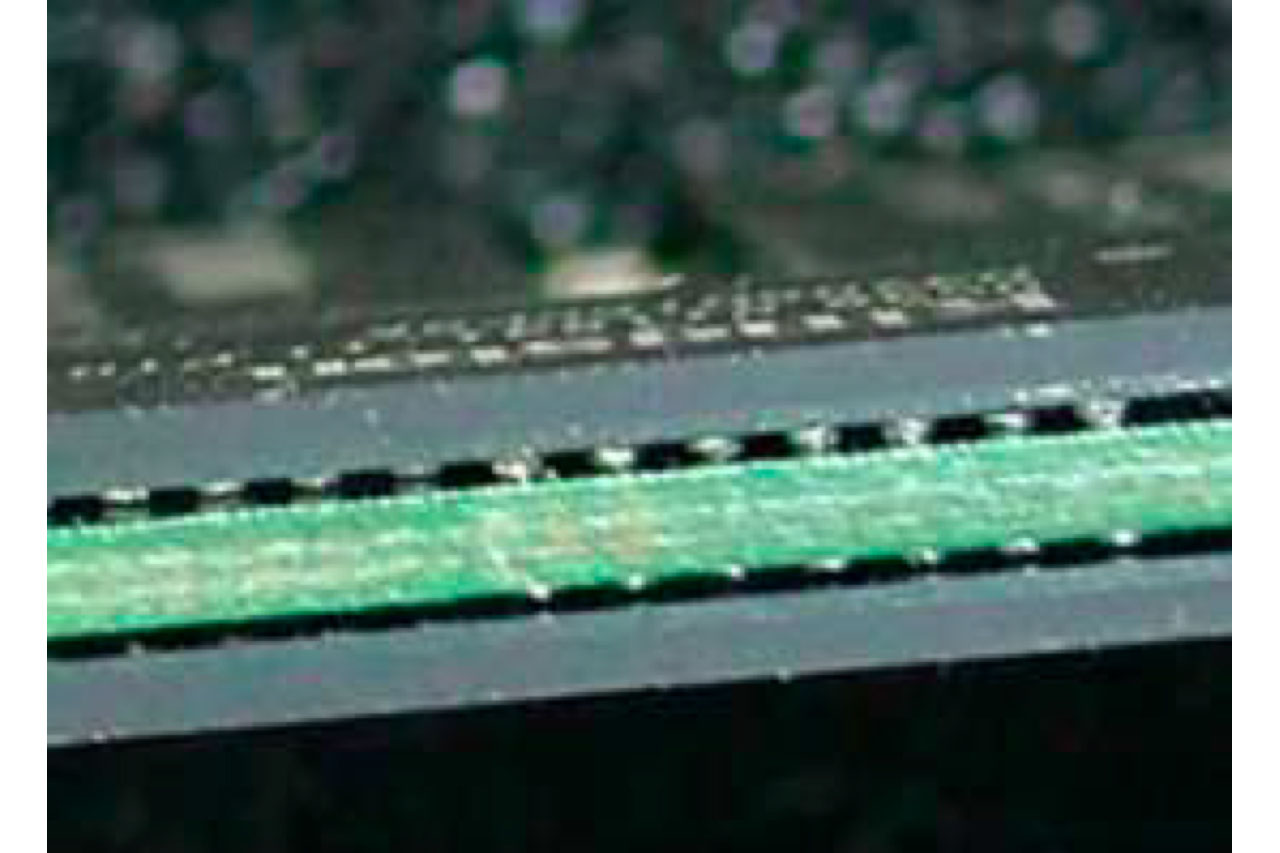

When BGAs are placed back-to-back on opposite sides of a two-sided PCB, this configuration presents challenges due to the increased density in the rework area. Typical rework methods involve preheating the board using a heat source located beneath it. In the case of mirrored BGAs this process can expose the underside BGA to prolonged heat, increasing the risk of damage and warping. It may cause the underside BGA to enter reflow, resulting in solder anomalies, joint embrittlement, and potentially leading to heavier components detaching from the board.

Mirrored BGA applications demand precise thermal control since the lower BGA will get quite close to reflow temperature due to its position relative to the BGA above and due via conduction of heat through the circuit board. Thermal profiling is critical when reworking boards with mirrored BGAs and it is essential to attach a thermocouple near the center and to two corners of the BGA to monitor temperatures during the rework process.

Our knowledgeable staff of IPC 7721 certified technicians have extensive experience in overcoming issues posed by mirrored BGAs. One effective strategy is to utilize localized heating methods with precise temperature control, to minimize heat exposure to surrounding components. Employing thermal shields, such as aluminum foil or specialized thermal pads, can protect the underside BGA from excessive heat during rework. Additionally, using low-temperature solder materials or techniques that allow for shorter heating cycles can significantly reduce the risk of thermal damage and warping.

About BEST Inc.

BEST Inc. is an ISO 9001:2015 and ITAR certified provider of BGA reballing, PCB and component rework services, focusing on quality, reliability, and sustainability. With a commitment to innovation, and customer satisfaction, we leverage advanced technologies to deliver comprehensive solutions for the electronics industry.