A wide-type model based on the YRH10, compatible with 12-inch wafers and capable of transporting large PCBs.

Yamaha Robotics will launch the new YRH10W hybrid placer on March 1. The YRH10W features the functions of both a surface mounter[1] for mounting electronic components onto printed circuit boards and a die bonder[2] for handling semiconductor chips.

The YRH10W is a wide-type model based on the existing YRH10 hybrid placer. It is compatible with increasingly mainstream 12-inch wafers while also capable of transporting large printed circuit boards up to L510 × W460 mm in size. Combining the excellent mounting accuracy from the YRH10 with the high-speed placement technologies refined through Yamaha Motor’s lineup of surface mounters gives the YRH10W an outstanding bare-chip placement speed of 14,000 CPH[3] when supplied with wafers and a high mounting accuracy of ±15 μm. It also comes with a wide variety of functions delivering ample versatility, allowing a single machine to handle diverse production processes.

The YRH10W will be on display for the first time at NEPCON JAPAN 2026, Asia’s leading exhibition for electronics R&D, manufacturing, and packaging technology, to be held at the Tokyo Big Sight from January 21 (Wed.) to January 23 (Fri.), 2026.

Market Background and Product Outline

With the rise and spread of New Energy Vehicles (NEVs) in recent years, the automotive electronics market is demanding highly efficient power conversion and high reliability, driving growing demand for power modules. In response, a shift to production using 12-inch silicon wafers, which leads to lower unit costs for chip components, is gaining momentum across the entire semiconductor market, and as a result, this is also driving up demand for mounting equipment compatible with these 12-inch wafers. In addition, for the mounting of power modules intended for NEVs, needs are increasing for batch mounting processes in which multiple individual circuit boards are arranged on a large carrier and mounted collectively for efficiency. Accordingly, requirements for transporting large carriers are also increasing.

To address these evolving market demands, Yamaha Motor developed the YRH10W as a hybrid placer that retains the high speed and accuracy of the existing YRH10, while adding 12-inch wafer compatibility and large PCB transport capabilities. Furthermore, it boasts a wide range of functions to provide high versatility and enable support for diverse production processes, including modular products.

Under its proprietary 1 Stop Smart Solution concept, Yamaha Motor is the industry’s leading manufacturer of a full lineup of mounting equipment, including surface mounters, printers, dispensers, and inspection systems By leveraging this strength, the Company is promoting the Intelligent Factory, a smart system that comprehensively improves the efficiency of the mounting process through smooth and advanced inter-equipment coordination without black boxes in equipment within the mounting line.

YRH10W Features

1) High-Speed, High-Accuracy, and High-Quality Mounting

By combining the high-accuracy placement technologies developed for the YRH10—including optimized axis control and thermal compensation functions—with the high-speed placement technologies refined through Yamaha Motor’s surface mounters, the YRH10W delivers both high productivity, with a bare-chip placement speed of 14,000 CPH when supplied with wafers, and a high accuracy of ±15 μm.

In addition, by utilizing Mounting Height Compensation and Load Control features that measure PCB height and warpage, the YRH10W achieves highly repeatable, high-quality mounting.

Furthermore, using the All Image Tracer function, which saves component recognition images, enables early detection of potential causes of defects—such as mounting failures or pick-up errors—and helps maintain and further improve mounting quality.

2) High Versatility

As with the YRH10, the YRH10W supports mixed mounting of surface-mount devices and wafer components, but in addition, expanding compatible wafer sizes up to 12 inches gives users the ability for multi-die mounting with 6-inch, 8-inch, and 12-inch wafers with a single platform.

The high-rigidity conveyor, which also contributes to high-accuracy mounting, supports the transport of large PCBs up to L510 × W460 × H20 mm in size.

Furthermore, a variety of versatile features, such as the Solder Paste Transfer Unit and the Fiducial Camera Z-axis Variable Function, enable support for diverse production processes, including modular products.

3) Easy Operation

As with the YRH10, the Wafer Pickup Condition Setup Utility enables visual setup of wafer component pickup conditions, allowing easy setup without requiring any special skills.

In addition, a number of support features—including placement sequence optimization and cycle time estimation—have been enhanced to help maximize overall equipment performance.

Furthermore, as a common feature of YR Series platforms, the YRH10W adopts a stylish, easy-to-read, and user-friendly graphical interface to make operation simple.

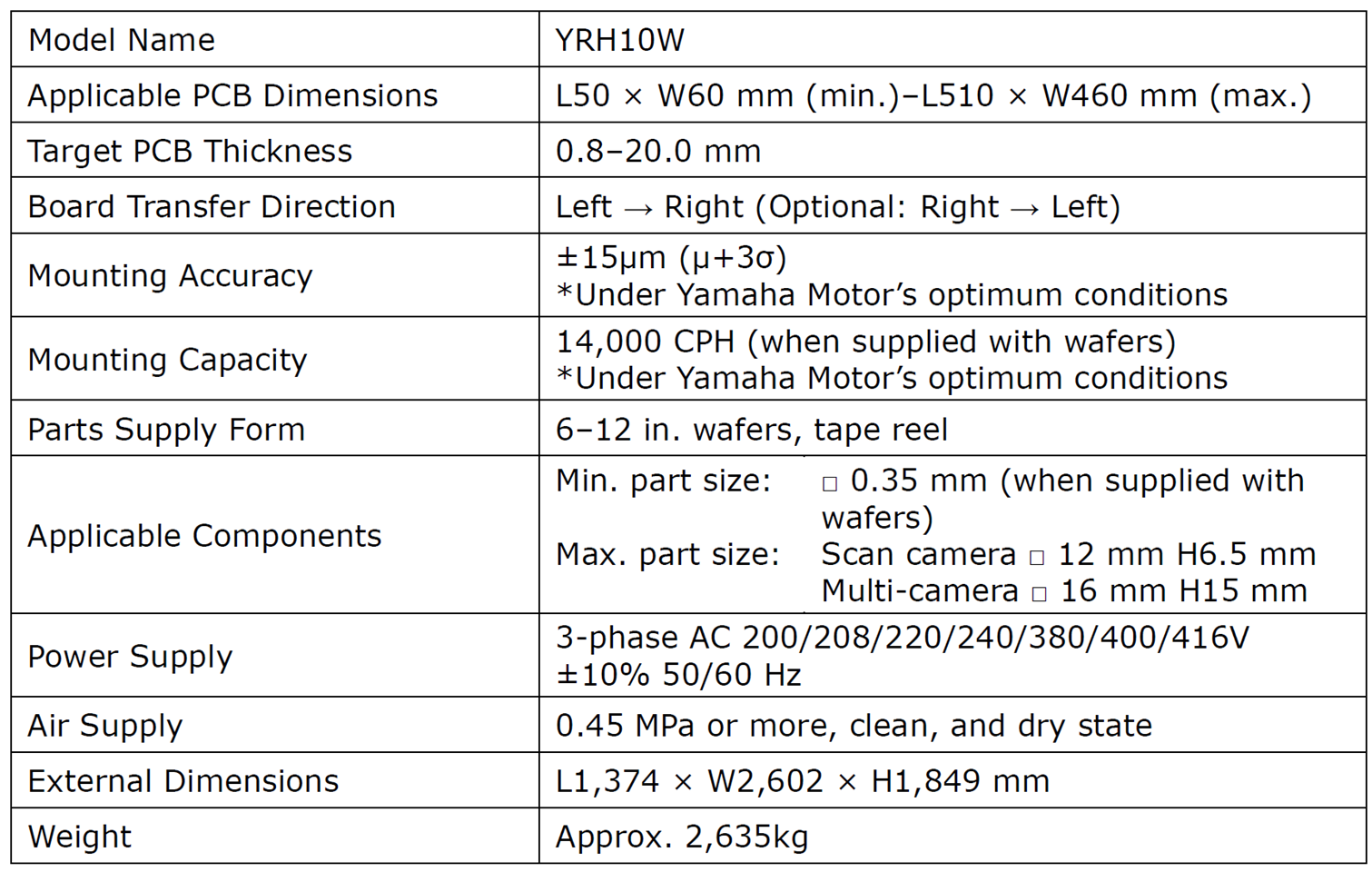

Basic Specifications

[1] Production equipment designed to mount various electronic components onto printed circuit boards (PCBs), which are then incorporated into electronic products.

[2] Production equipment that directly attaches semiconductor chips (dies/bare chips: exposed IC chips prior to packaging) onto printed circuit boards.

[3] Chips Per Hour: Total number of chips that can be mounted per hour (unit time). Indicates processing capacity under various conditions.

About Yamaha Robotics SMT Section

Yamaha Surface Mount Technology (SMT) Section, a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, produces a complete selection of equipment for high-speed inline electronic assembly. This 1 STOP SMART SOLUTION includes solder paste printers, component mounters, 3D solder paste inspection machines, 3D PCB inspection machines, dispensers, and management software.

Bringing the Yamaha way to electronics manufacturing, these systems prioritize intuitive operator interaction, efficient coordination between all inline processes, and modularity enabling users to meet the latest manufacturing demands. Group competencies in servo-motor control and image recognition for vision (camera) systems ensure extreme accuracy with high speed.

The current product line includes the latest YR equipment generation, with advanced automated features for programming, setup, and changeovers, and new YSUP management software with state-of-the-art graphics and built-in data analytics.

Combining design and engineering, manufacture, sales, and service competencies, Yamaha SMT Section ensures operational efficiency and easy access to support for customers and partners. With regional offices in Japan, China, Southeast Asia, Europe and North America, the company provides truly global presence.