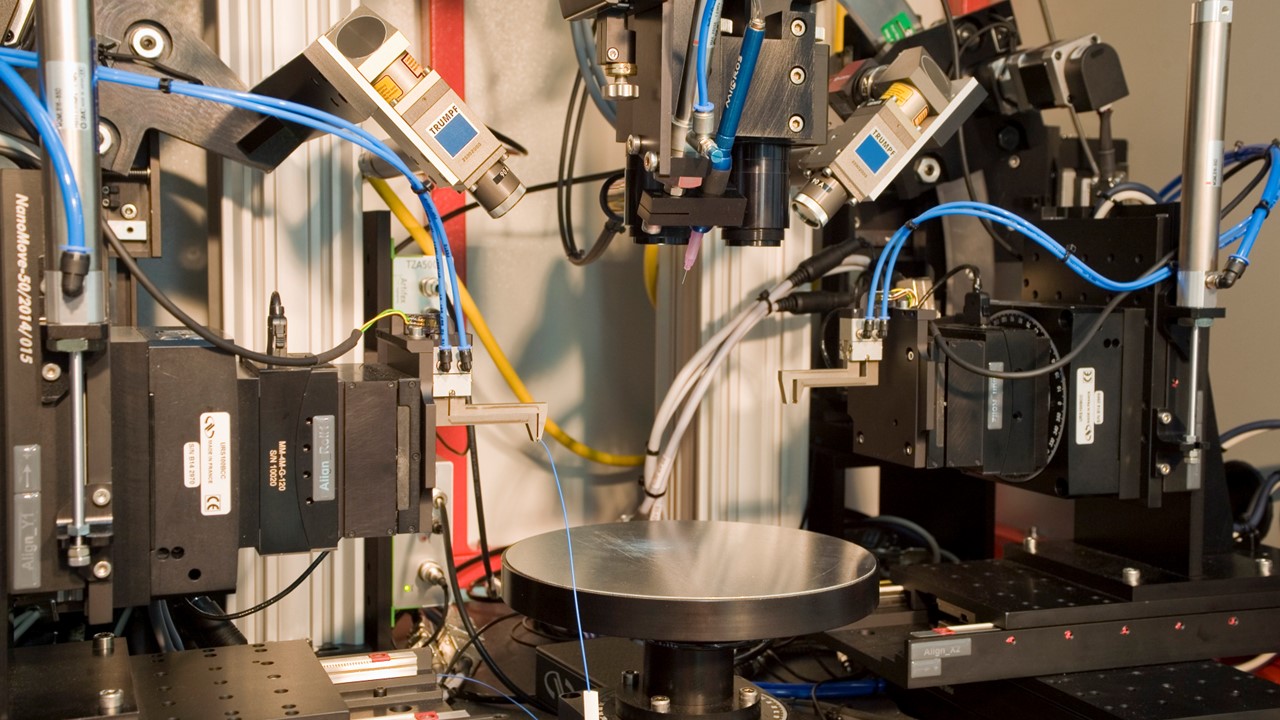

The assembly of optoelectronic components requires maximum precision and permanently stable connections. With NanoHybrid, nanosystec offers a modular platform that combines epoxy bonding, laser welding, and selective laser soldering in a single system, therefore providing maximum flexibility in the manufacturing of photonics, optoelectronics, and packaging.

Epoxy bonding remains the most economical technology currently available and allows almost all materials to be joined, while larger gap dimensions can be adjusted and mechanical pre-processing costs are reduced. However, polymer-based composites reach their limits in highly dynamic or cryogenic environments. Laser welding, on the other hand, offers the highest long-term stability, minimal positional displacement, and short process times. However, it requires metallic and gap-free contact surfaces and is therefore particularly suitable for series production. Selective laser soldering closes the gap between the two processes. The use of solder paste or pre-forms creates metallic bonds that are significantly more resistant to temperature changes and electromagnetic radiation than adhesives. This is particularly relevant for gold-plated optical fibers and fiber arrays in cryogenic quantum processors, where optical couplings must remain stable even after numerous thermal cycles.

All three processes benefit from active alignment in the nanometer range. Regardless of the joining process selected, components are first optically aligned for maximum coupling and only then permanently fixed in position. This minimizes coupling losses, improves the quality of the joints, and increases reproducibility, even for complex hybrid assemblies.

“With our NanoHybrid, manufacturers can select the optimal joining process without changing equipment, depending on the material mix, thermal load profile, and degree of integration,” explains Jan Kallendrusch, CTO of nanosystec GmbH.

The platform supports both manual and automated assembly, offers standardized interfaces, and enables scalable process automation from prototype production to small series.

“This makes NanoHybrid ideal for development laboratories and small series production, both in manufacturing companies and research institutes that require agile, precise, and stress-resistant joining processes,” adds Guenter Hummelt, Managing Director of nanosystec GmbH.

By combining universal material compatibility, maximum long-term stability, and temperature-resistant, gap-bridging metal connections, NanoHybrid marks a decisive technological step forward for development with increasing optical integration density and cryogenic operating conditions, as they are increasingly required in quantum computing.

nanosystec will be presenting its solutions from January 20 to 22 at booth 3281 at SPIE Photonics West in San Francisco.

To learn more, visit www.nanosystec.com.

About nanosystec:

nanosystec GmbH develops and manufactures high-precision assembly and testing systems for industrial series production. Based in Gross-Umstadt near Darmstadt, the company has been a partner to leading manufacturers in optoelectronics, medical technology, the automotive industry, and aerospace since 2001. The systems are based on finely tuned motion control and integrate processes such as precision laser welding, UV micro-bonding, and fine balancing. Thanks to modular platform architecture and high repeatability in the submicrometer range, both highly flexible and cycle time-optimized production solutions can be realized. In addition to standard modules, nanosystec also offers customized complete solutions including process development, integration, and lifecycle support.