Apollo Seiko, a leading innovator in soldering technology, will showcase its largest APEX presence to date in Booth 1300, featuring a full 30×40-ft display dedicated to next-generation selective soldering technology and advanced soldering automation. The booth will highlight three selective systems—including two new inline platforms, and a dual-pot selective system—along with three of the company’s industry-proven soldering robots.

Two New Inline Selective Soldering Systems Take Center Stage

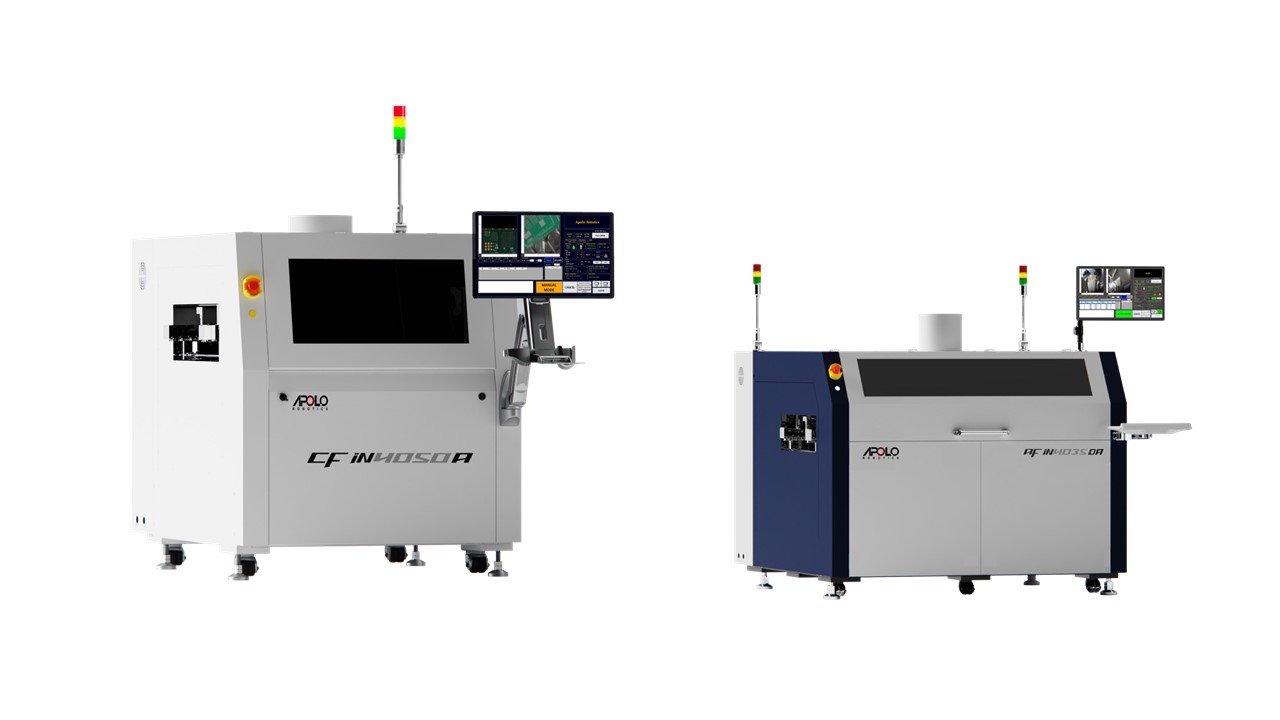

Apollo Seiko will debut its CF IN4050A Customizable Single-Pot In-Line System, the first model in its new Customizable Flow Series. Designed for manufacturers who need a precise, stable process but want flexibility in configuration, the CF IN4050A includes laser-based flow-height control, fiducial-based coordinate adjustment, and a 350°C solder-pot capacity. The platform can be upgraded with options such as automatic nozzle cleaning, auto solder feeding, advanced IR heating, nitrogen purity monitoring, vision-based flow adjustment.

Also making its APEX debut is the AF IN4035DA Dual-Pot In-Line System, a major step forward for high-mix or dual-alloy production. This new “three-in-one” configuration combines dual fluxing, top-side IR preheating, and dual solder pots in a single inline module. Key capabilities include laser-based flow-height control, automatic coordinate correction, auto solder feeding, optional MES connectivity, and nitrogen-purity monitoring. With two fully controlled solder pots running in parallel, users can process different alloys, different nozzle sizes, or different program strategies without stopping the line—dramatically increasing throughput.

Returning Highlight: EF 3040A All-in-One Selective Soldering System

Apollo Seiko will again feature the EF 3040A, a system that earned industry recognition for its clean, efficient design. The machine’s patented direct-drive motor and impeller minimize sludge, dross, and airborne dust, reducing maintenance and improving long-term consistency. The EF 3040A supports both live teaching and Gerber-based programming, includes a large 6.5-kg solder pot for longer uninterrupted runs, and integrates real-time flux and nitrogen sensors to stabilize the process and shorten cycle times.

Expanded Automation Lineup

In addition to the three selective systems, Apollo Seiko will display three soldering robots, offering visitors a full look at automation options for point-to-point soldering, repeatable fine-pitch applications, and production environments where manual soldering can no longer keep pace with quality or volume requirements.

A Larger Booth, a Stronger Focus

“This is our biggest APEX footprint yet, and it reflects just how much selective soldering has evolved,” said Rick Schiffer, President of Apollo Seiko. “Manufacturers need cleaner processes, higher uptime, and more flexibility. The new CF IN4050A and AF IN4035DA were built with all of that in mind.”

Apollo Seiko invites attendees to Booth 1300 to see live demonstrations and talk with engineers about optimizing selective soldering for high-mix, high-reliability production.

For more information, visit www.apolloseiko.com.