SHENMAO Technology, Inc. has introduced its new SMF-TA52 transient adhesive, a material created specifically for the growing use of formic acid reflow soldering in semiconductor packaging and other high-reliability electronics.

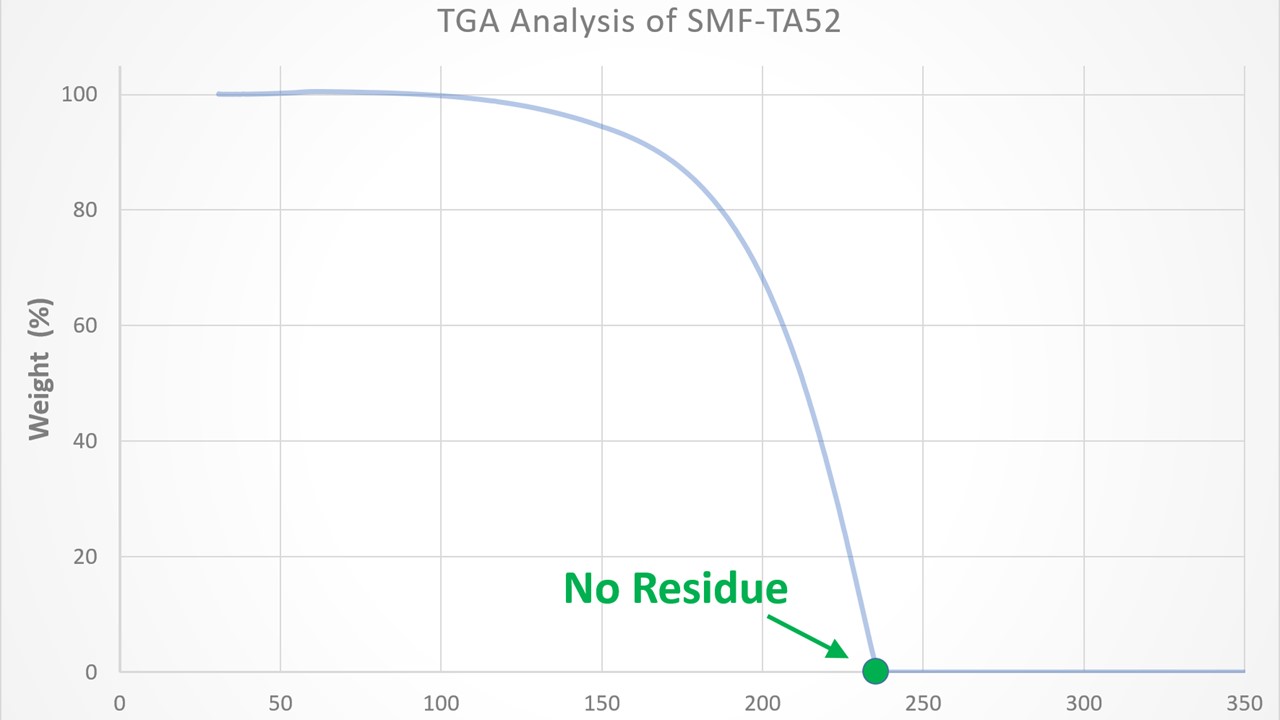

Formic acid reflow is gaining traction because it removes the need for traditional flux. By using formic acid as the reducing agent, the process clears metal oxides during heating and produces clean, low-void solder joints with no residue left behind. This makes it a good fit for applications that cannot tolerate contamination, such as automotive power devices (IGBTs, MOSFETs, diodes), copper pillar bumping, SiP modules, and packages that need strong thermal performance.

A Material Built for the Process

The new SMF-TA52 adhesive was formulated to hold solder preforms, dies, and wafers in place during assembly without interfering with the reduction chemistry inside the reflow oven. As the temperature rises, the adhesive breaks down gradually and reaches zero residue at peak reflow, eliminating any need for cleaning afterward.

SMF-TA52 is SVHC-free, halogen-free, and no-clean, aligning with the strict material requirements common in advanced semiconductor and power-module manufacturing.

Key Advantages

- Works with formic acid reflow, vacuum reflow, and silver sintering

• Provides strong, stable adhesion with a longer open time

• Suitable for both dispensing and jetting

• Leaves no residue after reflow

• Meets global environmental and regulatory expectations

SHENMAO continues to expand its materials portfolio for semiconductor packaging as manufacturers look for cleaner processes, tighter tolerances, and more reliable thermal performance. SMF-TA52 gives engineers a purpose-built adhesive that fits directly into those requirements.

To learn more about SHENMAO’s high-performance solder materials, visit www.SHENMAO.com.