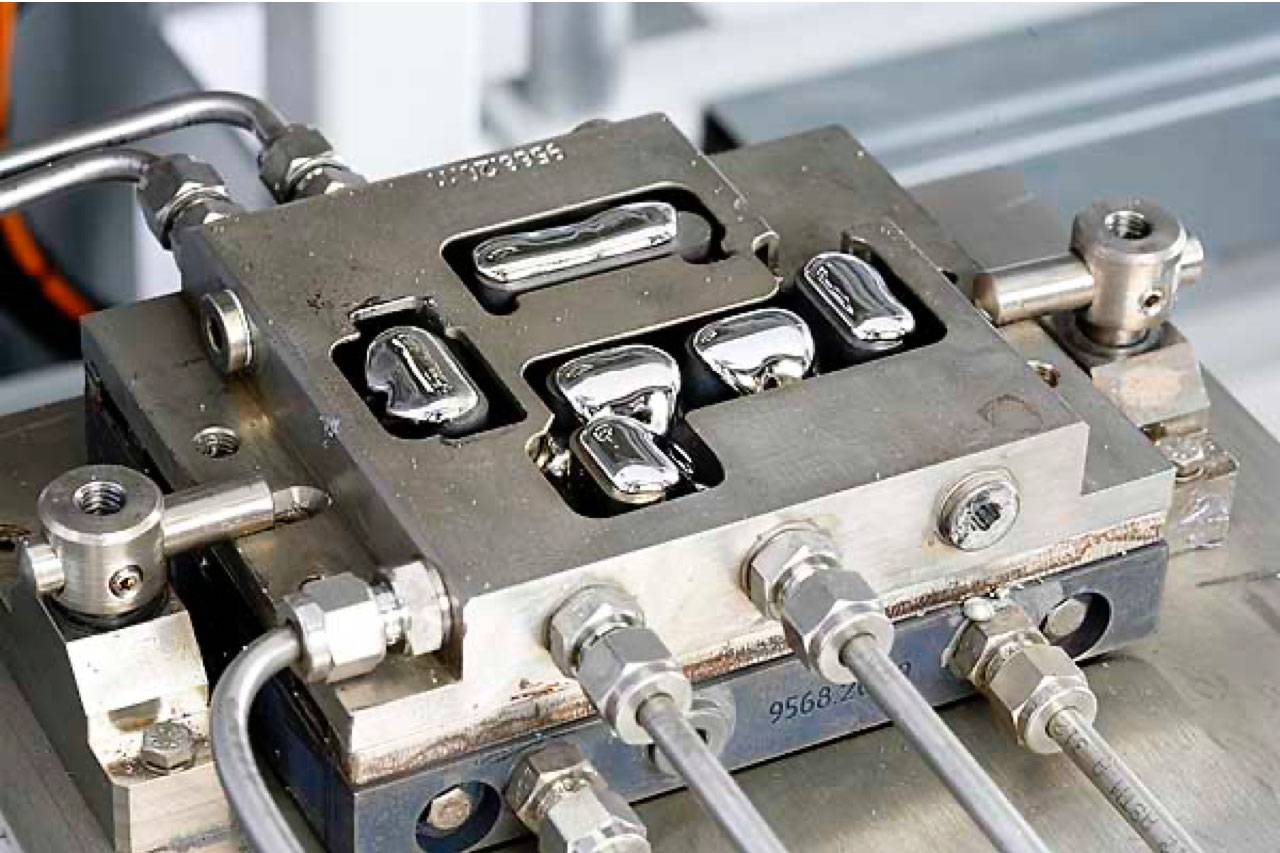

In mini wave soldering, the nozzle, in combination with the titanium soldering mask, plays a central role in the process. In addition to workpiece carriers and masks, Eutect also develops soldering nozzles according to customer and process-specific requirements. The specialist for selective soldering combines the highest manufacturing precision with comprehensive material expertise.

“The nozzle shapes and stabilizes the solder wave, ensuring that the liquid solder hits the designated solder pads at a defined height and optimal flow velocity. This targeted solder flow is crucial to ensure clean wetting while preventing unwanted solder spreading,” explains Matthias Fehrenbach, Managing Director of Eutect GmbH. The titanium solder mask completes this function by precisely defining the contact areas to be exposed and shielding sensitive components or conductor track structures. Furthermore, integrated baffles, pressure chambers, and other geometric design elements channel and control the solder flow. The combination of these elements results in a high-precision mini wave soldering process that delivers reliably reproducible results even with closely spaced solder points. Eutect manufactures the solder masks according to customer specifications.

A key advantage of custom-made nozzles, masks, and workpiece carriers is their high degree of individual adaptability. Since the shape, diameter, and outlet geometry of the nozzle can be precisely matched to the opening structure of the titanium solder mask, it is possible to process even complex assemblies, for example with different component heights or varying thermal masses, without compromising soldering quality. The nozzle ensures an even solder supply, reduces turbulence in the solder wave, and thus stabilizes the process. This combination also optimizes heat protection. While the nozzle focuses the heat input spatially, the titanium solder mask acts as an additional thermal barrier. Neighboring components are thus protected from unnecessary heat exposure, minimizing material stress within the assembly.

Eutect therefore does not consider the solder nozzle to be an isolated element, but rather an integral part of the entire soldering process. Since the component is developed entirely in-house by our own engineering department, we can guarantee a high degree of flexibility, precision, and optimal coordination with soldering systems, process modules, and automation solutions. Experience gained on an ongoing basis is incorporated into the further development of the technology, supported by modern simulation and measurement technology.

About EUTECT

For almost 30 years, soldering and joining systems have been developed, manufactured, installed, and programmed at EUTECT as well as at customers operating worldwide. The Swabian team of experts offers an extensive, constantly evolving module construction kit for process solutions in the field of soldering.

Process-related and commercially optimal modules for the task description will be selected from a wide variety of soldering-technology process modules and combined into proven stand-alone, revolving, or inline production designs for complete solutions.

The EUTECT module construction kit shows that a slim, individual solution comprising proven building blocks for a customer product’s task description can often be achieved via individual modules or free combinations.

A technologically comprehensive, innovative EUTECT technical center is available for optimal solution through evaluation or the manufacture of A-B-C prototypes ready for serial production.