In medium-volume assembly manufacturing, flying probe testers are becoming increasingly popular for in-circuit inspection and programming due to their high performance. GÖPEL electronic offers integration packages for these testers to seamlessly incorporate boundary scan into the test routines. Such a solution is now available for Takaya’s APT-2600FD flying probe tester. This eliminates the need for manual contacting of the PCBA, saving time-consuming handling steps. Component testing, boundary scan, programming, and functional testing are thus performed on one and the same system.

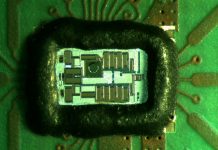

The Takaya APT-2600FD system with the multiprobe option allows users to flexibly contact their own pad geometries with a mini adapter. The multiprobe is implemented as standard on the underside as an alternative tool to a bottom probe. This enables compact contacting of JTAG-relevant signals, including the board supply. All JTAG/boundary scan tests and component programming can thus be integrated into a fully automated inline system with loader and unloader. The integration package is based on the SCANFLEX II CUBE architecture and contains specially tailored components for the Multiprobe option. Thanks to the smooth handshake between the Takaya APT and GÖPEL electronic software, electronic assemblies can first be MDA and boundary scan tested, then programmed, and finally function tested.

About GÖPEL electronic

GÖPEL electronic develops and manufactures innovative electrical and optical test, measurement, and inspection equipment for electronic components and printed circuit board assemblies as well as industrial and automotive electronics systems. GÖPEL electronic has four business units:

– Automotive Test Solutions

– Embedded JTAG Solutions

– Inspection Solutions AOI-AXI-SPI-IVS

– Industrial Function Test

The company is active worldwide, with its own subsidiaries as well as through distributors, and generated sales of approximately 40 million euros in 2023 with 240 employees.

Further information: www.goepel.com/en