WEVO-CHEMIE GmbH introduces WEVOSIL 23010 and WEVOSIL 23030, two new liquid silicone rubbers (LSRs) specially developed for silicone textile coatings and sealing applications (CIPG/FIPG). Both systems combine excellent processability with high elasticity, temperature resistance and adhesion. They open up new possibilities for precise and automated manufacturing processes using dispensing on textiles, plastics and metals.

Designed for use under a wide range of environmental conditions, these two new liquid silicone rubbers from Wevo offer a temperature range from –60 to +200 °C and also demonstrate excellent behaviour in thermal shock tests. The mechanical properties optimised for these applications further contribute to the materials’ high durability.

WEVOSIL 23010: self-adhesive, extra-soft LSR for textiles

WEVOSIL 23010 – a very soft LSR silicone (Shore A 10) – combines high elasticity with robustness, offering an elongation at break of over 900 per cent and a tensile strength of 5.5 N/mm². It also provides good initial adhesion on textiles or polymer surfaces without the need for primers.

The material is suitable, for example, as a silicone textile coating to reinforce technical textiles. It can also be used for permanently bonding textile layers and embedded electronics. These properties enable the manufacturing of smart textiles, such as protective clothing for firefighters or military applications as well as sportswear with extended functionalities.

WEVOSIL 23030: classic LSR for fuel cells and electronics

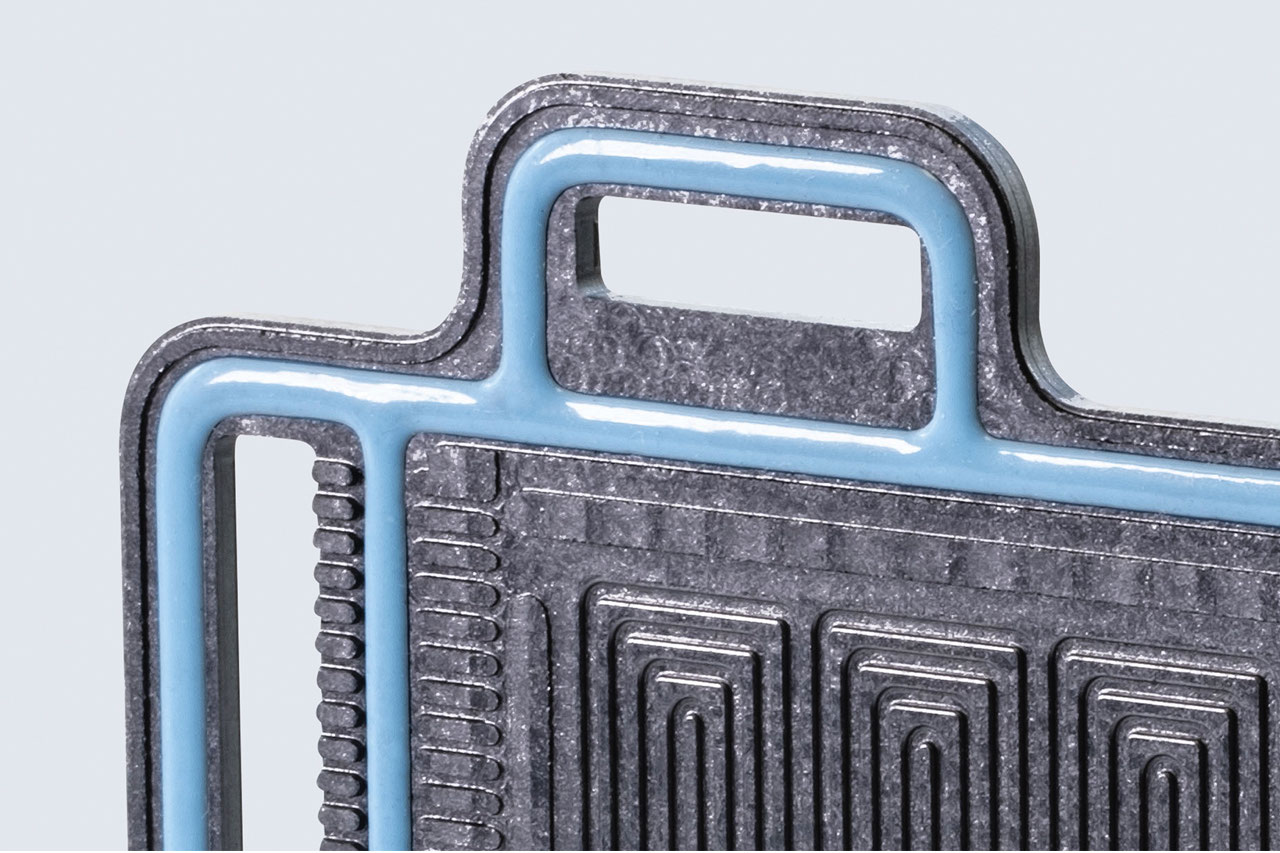

With WEVOSIL 23030, Wevo is expanding its portfolio to include a classic LSR silicone (Shore A 30) offering slightly higher strength and excellent mechanical properties, including an elongation at break of over 500 per cent and a tensile strength of 5.0 N/mm². After post-curing, the material exhibits good adhesion to substrates such as metals and plastics, making it particularly suitable for applications with demanding requirements in terms of long-term stability and temperature resistance.

Dispensing opens up numerous fields of application. A key focus is sealing as Cured- or Formed-in-Place Gaskets (CIPG or FIPG) in stacks and bipolar plates for fuel cells and electrolysers, as well as the attachment of electronic components to clothing for extended functionalities.

Efficient processing via dispensing

Their uniform cross-linking without abrasive fillers means both of these liquid silicones can be precisely and reliably applied in fully or partially automated production processes. In addition, processing parameters such as flow behaviour, pot life and curing speed can be accurately adapted to suit individual customer requirements on request. This enables seamless integration into existing production lines or the use of alternative application methods alongside dispensing.

The new LSR materials from Wevo thus provide flexible solutions for precise sealing and functional coatings across a wide range of industries.

About Wevo

WEVO-CHEMIE GmbH is an independent manufacturer in the field of customised potting and casting compounds as well as adhesives and sealants based on polyurethane, epoxy and silicone – primarily for use with electrical and electronic components. Wevo products protect sensitive components against chemicals, vibration, foreign matter, dust, humidity and high temperatures. We supply to more than 1,250 customers in over 50 countries from our headquarters near Stuttgart, Germany, and through companies in Asia, China and the USA.

Image Credit: © University of Technology Chemnitz / WEVO-CHEMIE GmbH