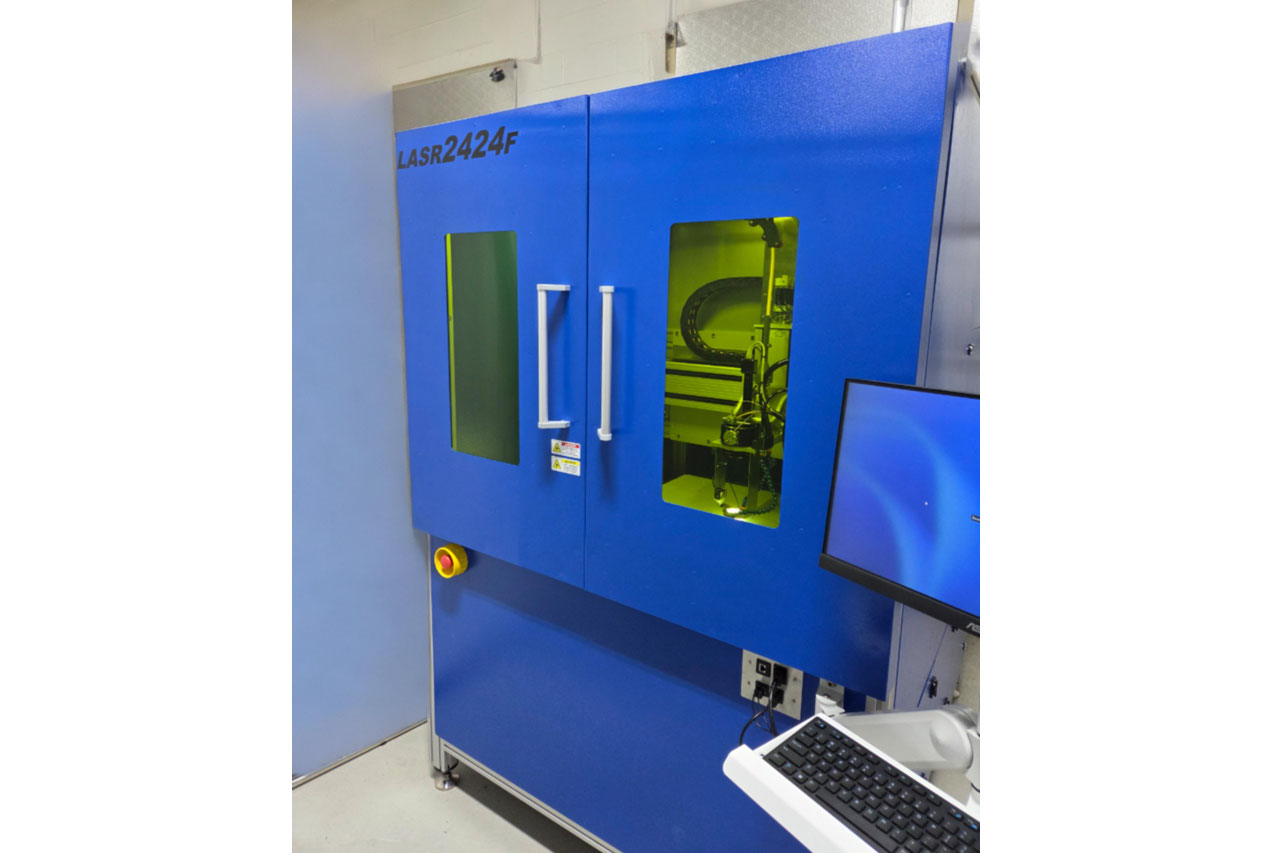

Bold Laser Automation, Inc. has announced the release of its new LASR2424F Laser Automated Solder Reflow System, engineered for high-precision, automated solder reflow of flat and semi-chambered substrates. Designed and manufactured at the company’s New Hampshire facility, the LASR2424F represents a significant advancement in precision laser processing for high-reliability electronics manufacturing.

Built on Bold’s industrial-hardened LPC architecture, the LASR2424F integrates a 300-watt SPI/Trumpf continuous-wave fiber laser with galvanometer-based beam delivery, providing a tightly focused and highly stable optical process for reflow soldering applications. The system delivers ±0.0015-inch (±0.037 mm) laser centroid accuracy and supports substrate sizes up to 24 x 24 inches (600 x 600 mm).

Engineered for advanced PCB and high-frequency component applications, the LASR2424F features:

- Integrated X-Y-Z motion control with closed-loop encoders and laser triangulation feedback for real-time focus correction.

- Inline and off-axis vision alignment for pre- and post-process inspection, utilizing OMRON or equivalent high-resolution machine vision.

- BOLD Polaris NC/CAD-CAM control platform, allowing direct import of CAD DXF/DWG files and automated G-code generation for streamlined programming.

- Vacuum chuck and pin tooling for precise fixturing of flat and curved substrates.

- Class 1 laser enclosure meeting CDRH and FDA laser safety standards.

The LASR2424F system optimizes the solder reflow of specialized assemblies with repeatable, high-speed reflow of multiple eyelets per second. This system improves overall production throughput with automated verification and mapping, reducing manual alignment steps.

“Our LASR2424F system demonstrates the precision and flexibility achievable when laser-based automation meets intelligent motion and vision control,” said Todd E. Lizotte, CEO and co-founder of Bold Laser Automation. “It’s built for engineers who demand both accuracy and adaptability in high-mix, high-performance electronic assembly environments.”

Bold Laser Automation’s LASR2424F system is available for integration into new or existing manufacturing lines. The platform can be customized for flat-panel, hybrid, and microwave substrate processing, and can be configured with nitrogen or argon purge optics for debris-free operation.

Learn more about solder reflow with our Knowledge Center article, “Two Types of Lasers Transform Reflow Solder Processes on Circuit Boards” here.

About Bold Laser Automation

Bold Laser Automation, Inc., specializes in advanced laser solutions for precision cutting, welding, measuring, and inspection applications. With a focus on high-performance, reliability, cost effectiveness, and customer satisfaction, Bold solutions are trusted by industry leaders worldwide.

To access the highly reviewed Laser Beam Shaping Applications, Second Edition, from Todd E. Lizotte, CEO and co-founder of Bold Laser Automation, see:

Laser Beam Shaping Applications – Google Books

Laser Beam Shaping Applications – Amazon Books