At productronica, Eutect GmbH will present its Multiple Process Changer (MPC) soldering system, which performs fully automated piston soldering using Mitsubishi’s MELFA ASSISTA collaborative robot. The system features a particularly simple manual teach-in mode, which is provided by the Eutect software EUTECT Machine Interface (EMI). This is the central control and operating platform for all movement and process sequences within an Eutect soldering system.

EMI precisely coordinates and controls all axes and robot movements, such as X, Y, Z, or rotary axes. The software also enables convenient management of products and jobs. Users can create, edit, or copy products and link them to specific codes or sequence programs. The integrated DAT editor or JobCreator can be used to graphically display, adjust, and optimize motion sequences, from defining individual points and lines to setting speeds, dwell times, or feed axes.

EMI’s range of applications has now been expanded with respect to future cobot applications. “In teach mode, I can manually move the cobot to the respective areas on the PCB that it needs to reach during the process. For this purpose, I move the cobot to the respective position. I can check the exact positioning on the monitor. If it is correct, it is transferred to EMI. This allows me to teach the process sequence step by step,” explains Lars Iwers, Marketing and Sales Manager at Eutect GmbH. This makes it extremely easy to teach and program new soldering processes, which can also be implemented in conjunction with EMI with other cobot and robot solutions.”

Eutect has many years of experience in the field of cobot integration. At the end of 2018, the Swabian soldering specialist integrated collaborative robots into its production cells for the first time. The R&D team has now converted the resulting experience into the development of the new EMI teach-in mode. The MPC in combination with EMI will be presented at productronica with a piston soldering head. “We see the MPC automation platform as a flexible solution that can be equipped with different soldering processes for different AIT applications, depending on customer requirements,” says Fehrenbach, Managing Director of Eutect GmbH. The use of a wide variety of tools in a single work process is also being considered.

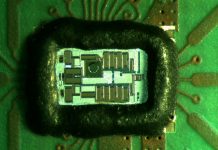

The MPC for piston soldering presented at the trade fair can be equipped with soldering iron systems from JBC or Hakko. The soldering iron is firmly mounted on the robot arm, including the wire feed. The robot, control systems, and soldering iron form a single machine unit.

The entire system is completed by the input area, which in the standard version consists of a rotary indexing table for manual assembly loading and a safety cell around the soldering process. The process area itself also features a soldering tip holder, which enables fully automatic soldering tip replacement. The same applies to tip cleaning. The rotary indexing table can be replaced by a conveyor system if required. This allows the soldering system to be operated either inline or automatically loaded and unloaded via an assembly carrier.

“At the trade fair, we will be showcasing the basic system, which can be customized to suit customer-specific processes. However, these customizations are carried out separately and are part of our special services,” explains Fehrenbach. It is also possible to integrate the robot, including soldering heads and subsystems, into other Eutect production cells. “At the trade fair, we will be demonstrating the possibilities available to inspire our customers to think in new ways and discover innovative solutions,” adds Fehrenbach.

Eutect GmbH will be exhibiting the MPC, including EMI teach-in mode, at productronica 2025 in Hall B2, Booth 439.

About EUTECT

For almost 30 years, soldering and joining systems have been developed, manufactured, installed, and programmed at EUTECT as well as at customers operating worldwide. The Swabian team of experts offers an extensive, constantly evolving module construction kit for process solutions in the field of soldering.

Process-related and commercially optimal modules for the task description will be selected from a wide variety of soldering-technology process modules and combined into proven stand-alone, revolving, or inline production designs for complete solutions.

The EUTECT module construction kit shows that a slim, individual solution comprising proven building blocks for a customer product’s task description can often be achieved via individual modules or free combinations.

A technologically comprehensive, innovative EUTECT technical center is available for optimal solution through evaluation or the manufacture of A-B-C prototypes ready for serial production.