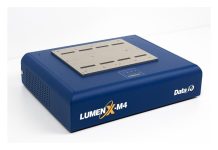

Solderstar, leaders in thermal profiling innovation, will unveil its latest patent-pending verification tool, the WaveShuttle O₂, at Productronica 2025, taking place from 18–21 November at Messe München, Germany. Building on the success of the original WaveShuttle, this advanced version adds real-time oxygen measurement, creating a comprehensive verification solution that captures all key process parameters from a wave soldering machine in a single pass.

WaveShuttle O₂ measures seven critical parameters: temperature profile, wave contact, wave height, line speed, inclination angle, process vibration, and oxygen concentration. The addition of oxygen monitoring allows engineers to correlate solder quality with atmospheric conditions, define and maintain optimal process ranges, and quickly detect leaks or gas supply issues, ensuring reliable, consistent solder joints and long-term process stability.

Chris Williams, Head of European Sales at Solderstar, said: “Wave soldering remains a critical process for electronics manufacturers, and WaveShuttle O₂ represents a major step forward in process verification. The addition of oxygen measurement gives engineers unprecedented control over the soldering atmosphere, while our multi-parameter approach monitors machine performance and board exposure with complete confidence, reducing defects and optimising throughput.”

The WaveShuttle O₂ features precision titanium contact sensors that directly measure wave contact, along with wave height and line speed. An integrated three-axis vibration sensor continuously monitors mechanical movement, detecting instability caused by worn components, misaligned tooling, or machine resonance. By identifying vibration-related risks such as skewed components, solder bridges, or disturbed joints, engineers can intervene early, reduce downtime, and implement predictive maintenance strategies to maintain stable, high-yield production conditions.

Inclination sensors measure actual angles the PCB will experience during wave soldering, revealing discrepancies due to program settings or poorly performing conveyor systems. This ensures boards enter and exit the solder wave at optimal angles, minimising bridging and enhancing joint quality. The system enables highly accurate conveyor adjustments and tracks gradual process drift over time, supporting repeatable solder performance across multiple production runs.

The integrated oxygen sensor monitors residual oxygen levels in real time directly within the soldering environment. This helps verify Nitrogen inerting performance, reduce oxidation and dross formation, and maintain stable, consistent solder joints. This is particularly valuable for lead-free soldering processes, which are more susceptible to oxidation.

Constructed from robust ESD composite and titanium materials, with custom productions sizes available, WaveShuttle O₂ integrates with Solderstar’s SLX datalogger platform, enabling manufacturers to distinguish between machine-level inconsistencies and PCB-specific issues. Its multi-parameter verification approach sets a new benchmark for wave soldering process control.

Visitors to Productronica 2025 will be able to view the WaveShuttle O₂ together with the new VP-10 Thermal Profiler and Vapor Shuttle Verification Fixture which are also being showcased.

The VP-10 captures 10 measurement channels for high-mass components, small passives, and critical board corners, providing comprehensive thermal coverage for both initial profiling and ongoing verification. The Vapor Shuttle Verification Fixture is a purpose-built tool for machine qualification, assessing temperature uniformity across vapour phase ovens to support consistent soldering conditions. Together, these products form part of Solderstar’s industry-leading verification suite, helping manufacturers maintain consistent solder quality, reduce rework, and optimise throughput across all soldering processes.

For more information, visit www.solderstar.com.