How Infrared BGA Rework Stations Reduce Thermal Stress in PCB Repair

As electronic components become smaller, denser, and more sensitive, the demand for precise and damage-free rework methods has grown dramatically. Nowhere is this more evident than in the rework of Ball Grid Array (BGA) components, critical parts in everything from smartphones to aerospace systems.

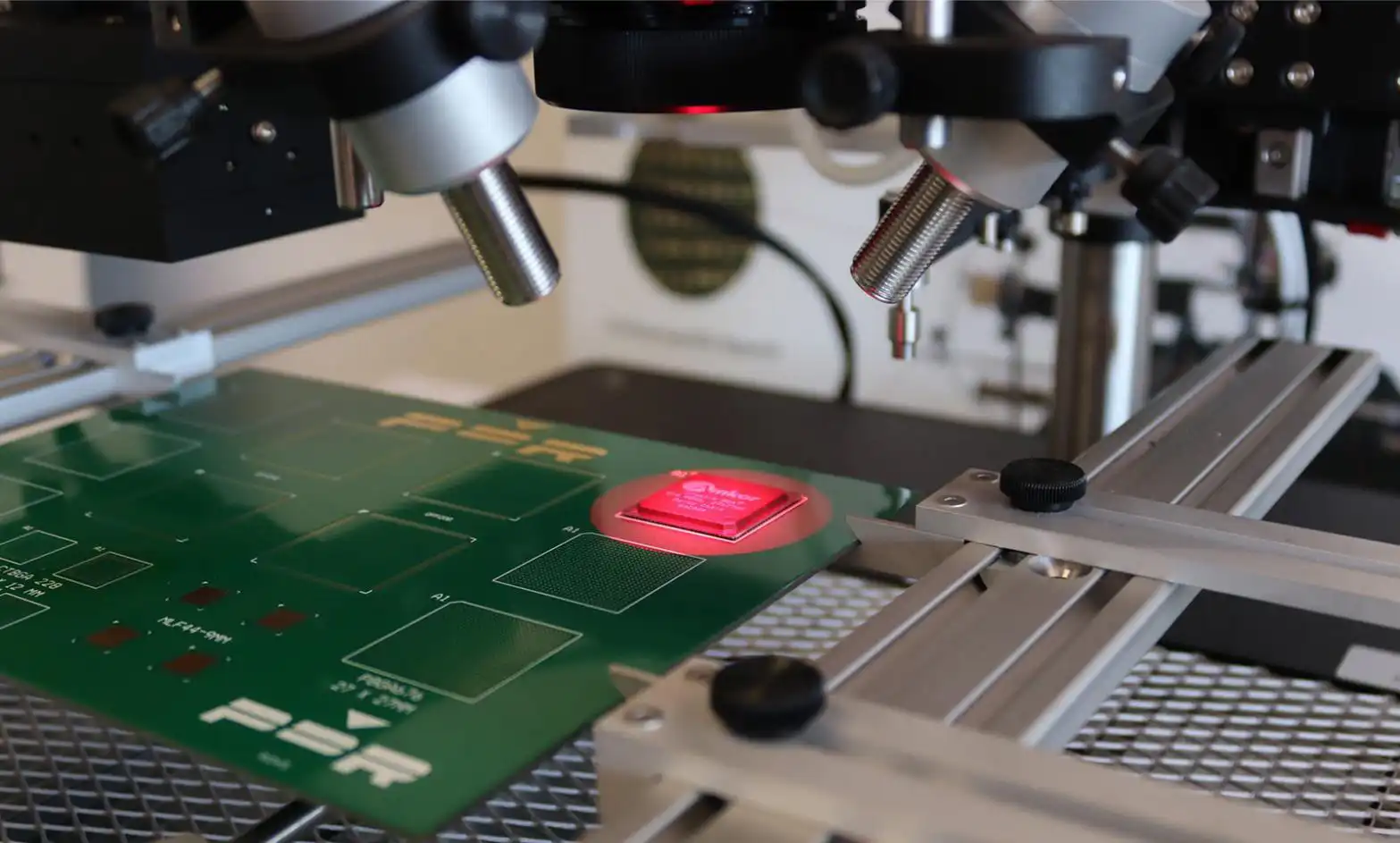

One of the most effective technologies in modern PCB rework is infrared (IR) heating, particularly when used in BGA rework stations. In contrast to traditional hot air systems, infrared rework offers a more controlled, less intrusive method of heat delivery, reducing thermal stress and improving overall repair reliability.

The Problem with Traditional Hot Air Rework

Hot air rework systems rely on forced convection to heat solder joints. While effective, this method often results in:

- Uneven heat distribution

- Component warping due to airflow

- Risk of dislodging adjacent small passives

- Higher thermal gradients that can cause pad lifting or PCB delamination

In BGA components, where solder joints are hidden beneath the device, controlling temperature precisely, without overexposing surrounding areas, is vital.

The Infrared Advantage in BGA Rework

Infrared systems use non-contact heat transfer, focusing energy directly onto the target component. Modern systems like those from PDR Rework use advanced IR emitters and thermal profiling to provide:

- Uniform heating across the entire BGA area

- No forced airflow, avoiding movement of nearby components

- Lower delta-T (temperature difference) between top and bottom layers of the PCB

- Minimised risk of reflowing adjacent joints

These benefits significantly reduce the chance of pad lift, trace damage, or latent solder joint failure, especially in multilayer and lead-free PCBs.

Systems Built for Precision

At Etek Europe, we supply a full range of PDR infrared BGA rework systems, designed to meet the needs of both entry-level and high-volume production environments:

- PDR IR-E1 | Compact, ideal for prototyping and repair

- PDR IR-E2 | BGA/SMT Rework Station for Small/Medium PCBs

- PDR IR-E3 | A versatile, mid-range system with advanced thermal control

- PDR IR-E6 | Optimised for large-format PCBs and high-throughput lines

- PDR IR-Q3 | Semi-automated for precision and repeatability

All models allow for profile creation, real-time thermal feedback, and component-specific settings, reducing operator error and repeat rework cycles.

Reducing Thermal Stress = Higher Yields

By reducing the thermal stress applied to the PCB and components during rework, manufacturers gain:

- Fewer board rejections

- Improved solder joint integrity

- Longer component and board life

- Lower total cost of repair

With increasing pressure to meet IPC and OEM standards, infrared-based rework delivers both compliance and confidence.

Sustainability and Cost Savings

Reducing rework-related damage isn’t just about quality, it also supports waste reduction and energy efficiency. Repairing a £400 BGA module vs. scrapping an entire board has enormous environmental and operational benefits.

As part of a sustainable manufacturing strategy, infrared rework is no longer a luxury, it’s an essential process improvement.

Learn More

To explore the full range of PDR infrared BGA rework stations and how they can support your production goals, visit: