KIC, the leader in smart thermal process technologies for electronics manufacturing, will exhibit its latest innovations at productronica 2025, taking place November 18–21 at Messe München in Munich, Germany. Visitors to Hall A4, Booth 214 are invited to discover how KIC continues to push the boundaries of process insight and control for today’s modern, connected factories.

KIC will feature its newest advancements in intelligent thermal management and real-time monitoring, including the Heat Map, Vapor Phase Shield, and Vibration Measurement technologies—each designed to deliver deeper visibility and precision across electronics manufacturing environments.

The KIC Heat Map maximizes profiler utilization by up to 84%, transforming it into a powerful real-time machine monitoring tool. It enables manufacturers to instantly visualize oven zone performance, detect hidden thermal drifts, and ensure process stability with clear, actionable insights. This innovation helps production teams move beyond static profiling toward continuous, intelligent process control.

The Vapor Phase Shield is engineered for both batch and in-line vapor phase reflow systems, with or without vacuum. Providing extreme protection up to 260°C, it ensures data accuracy and prevents device damage, even under vacuum pressure—empowering operators to gain precise thermal data in challenging reflow environments.

For those seeking full visibility into machine performance, KIC’s new Vibration Measurement capability monitors vibrations across three axes (X, Y, and Z) to pinpoint issues affecting quality and consistency. From fan speed to conveyor operation, this real-time insight enables fine-tuned adjustments that reduce defects and improve yield.

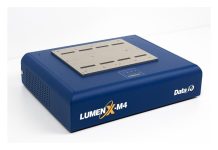

In addition to these cutting-edge features, KIC will demonstrate its Thermal Analysis System (TAS)—an advanced, AI-powered platform designed to simplify and elevate thermal profiling and process optimization. With a user-friendly interface and built-in analytics, TAS provides actionable insight in real time, helping manufacturers improve traceability, reduce setup time, and boost overall yield.

Built for high-mix, fast-paced production environments, TAS automates complex profiling tasks and delivers the intelligence needed to make confident, data-driven decisions. One of its most powerful features, KIC’s award-winning Common Recipe Finder, identifies a single optimal oven recipe that works across multiple assemblies—dramatically minimizing the number of profiles required, shortening changeovers, and improving oven efficiency.

Attendees are encouraged to visit KIC in Hall A4, Booth 214 to experience live demonstrations and see how the company’s intelligent hardware and software solutions are transforming process control in the electronics manufacturing industry.

To learn more, explore KIC’s solutions at www.kicthermal.com.