Inovaxe, a world leader and provider of innovative material handling and inventory control systems, will make a significant presence at productronica 2025, held November 18–21 at the Munich Exhibition Center. Demonstrations of Inovaxe’s latest offerings, presented through key strategic partnerships, will be on display across multiple booths.

Shared Booth with MODI: A2.568

Inovaxe will co-exhibit with MODI, showcasing its flagship material handling systems. One highlight is the SREX700-C stationary rack designed for efficient, space-saving storage of 7-inch component reels. For larger reels, the SREX130-12-C variant accommodates 13-inch spools with the same reliability and rack footprint. Notably, Inovaxe’s SR200-7-C mobile kitting rack offers flexible transport and feeding of components directly to the line, supporting lean manufacturing workflows. Production line-side efficiency is further enhanced with Inovaxe’s line-side rack, ensuring that components remain accessible at point of use. Adding another layer of practicality, InoBright transforms traditional OEM pick-and-place feeder carts into intelligent, traceable storage units providing real-time visibility into material locations, helping eliminate set-up errors, and reducing downtime.

Seamlessly Integrated with Panasonic PanaCIM: A3.177

As part of our strategic partnership with Panasonic Connect Europe, Inovaxe has integrated its intelligent storage systems directly into the PanaCIM material management platform on the Panasonic booth. This ensures seamless data flow, real-time inventory tracking, and optimized material handling across the factory floor.

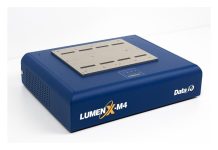

Our SREX700-C Smart Rack supports high-density storage for up to 880 7″ reels in a compact footprint and is fully engineered for direct connection to PanaCIM. The system automates inventory updates, eliminates manual errors, and ensures accurate reel location at all times.

The SR200-7-C mobile rack extends flexibility by accommodating 7″, 13″, and 15″ reels simultaneously while incorporating InoBar—a tracking and identification system that maintains real-time visibility of component inventory. Integrated with PanaCIM, it provides unmatched visibility and control over material flow from stockroom to production line.

These solutions are tailored to improve the speed and accuracy of Panasonic’s material workflows across complex production lines

Broader Industry Presence

Beyond MODI and Panasonic, Inovaxe’s material handling systems are also being featured by distribution partners Europlacer and Mancini. The appearance of Inovaxe’s racks in their booths reinforces the wide adoption of these solutions within advanced electronics manufacturing environments worldwide.

“Inovaxe focuses on practical solutions that directly enhance production line efficiency,” said Margy Khoshnood, Executive VP, Inovaxe. “Our collaboration with MODI and Panasonic, together with our presence through Europlacer and Mancini, emphasizes the growing demand for smart storage systems that deliver reliability, flexibility, space savings, and error reduction.”

Explore Inovaxe’s full lineup of material handling systems at productronica 2025, and learn how these innovations are shaping the future of electronics manufacturing.

To learn more, visit www.inovaxe.com