EVS International, the leader in solder recovery, is set to exhibit at productronica 2025, taking place November 18-21 at Messe München in Munich, Germany. Visitors to Hall A4, Stand 145 will have the opportunity to experience the industry-leading EVS 18KLFHS and EVS 500LFCABF systems — two powerful solutions that are redefining efficiency, safety, and sustainability in electronics manufacturing.

EVS 18KLFHS: Maximum Recovery, Minimal Waste

The EVS 18KLFHS is engineered to recover up to 80% of pure solder from dross, dramatically cutting waste and material costs while supporting environmentally responsible production. Its innovative fully sealed cabinet design with integrated fume extraction promotes a cleaner, safer shop floor, aligning with today’s strict health and safety standards.

At the heart of the system is EVS’s patented tilting pot and hot air–activated auto drain tap, which simplify operation and deliver exceptionally clean solder ingots with minimal operator input. With its large 18 kg (40 lb) capacity, the EVS 18KLFHS reduces dedrossing time by up to 75%, maximizes throughput, and minimizes downtime—making it an ideal solution for high-volume SMT lines as well as smaller production environments.

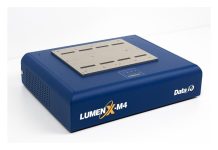

EVS 500LFCABF: Setting a New Standard for Solder Quality

The EVS 500LFCABF introduces breakthrough technology that strains recovered solder through a gauze, producing solder bars with exceptional purity and eliminating peppering from leftover dross. This results in higher-quality solder that meets the strict requirements of today’s electronics manufacturers.

Capable of recovering 60–85% of solder from dross, the EVS 500LFCABF dramatically reduces solder consumption by over 50%, cuts dedrossing time by 75%, and decreases offsite dross waste by up to 85%. Featuring high-efficiency flux extraction and advanced aqueous scrubber technology, it is compatible with most flux chemistries and designed for easy serviceability—ensuring consistent performance and a lower total cost of ownership.

Driving Sustainability and Cost Efficiency

Both the EVS 18KLFHS and EVS 500LFCABF enable manufacturers to reduce waste, improve shop-floor safety, and significantly lower material costs, helping them meet both operational and sustainability goals.

“We are excited to showcase these groundbreaking systems at productronica 2025,” said Simon Norman, General Manager at EVS International. “Our mission has always been to help manufacturers save money while reducing their environmental footprint, and these solutions represent the next step forward in achieving that.”

Join EVS at productronica 2025

Attendees are invited to visit EVS in Hall A4, Stand 145 to see live demonstrations of these systems and learn how they can transform solder recovery operations.

For more information about EVS International’s industry-leading systems, visit www.solderrecovery.com.