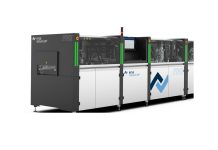

SASinno Americas has introduced the new Ultra Series, the latest generation of offline selective soldering systems. Available in two models—the Ultra-i1 and Ultra-i2—the new series is designed to meet the needs of manufacturers running small to medium batch sizes, multiple product types, and frequent line changes, while maintaining exceptional precision and process control.

Both machines come equipped with a suite of advanced standard features, including fiducial mark recognition (Sof-FICC), a high-precision Picor-type jet fluxing system (Flx-DropJetL), automatic nozzle cleaning (Flx-AutoClean), and dual top and bottom preheating zones for consistent solder performance. The maintenance-free electromagnetic pump (Sod-EMega), coupled with nitrogen heating and flow monitoring, ensures stable, repeatable soldering quality.

A user-friendly, Windows-based software interface makes setup and operation simple, while intelligent process monitoring tools—such as live soldering cameras, wave height calibration, and barcode tracking—support traceability and quality assurance.

Optional features like automatic solder wire feeding, nitrogen purity monitoring, solder pot exchange trolleys, and customized carriers or nozzles further expand the Ultra Series’ flexibility, allowing customers to tailor each system to their specific production needs.

“The Ultra Series was built with real-world production in mind,” said Mike Young, CEO/General Manager at SASinno Americas. “Our customers are managing more product changeovers and shorter lead times than ever before. The Ultra-i1 and Ultra-i2 combine the precision and automation they need with the usability and reliability they expect from SASinno.”

The Ultra Series delivers a smarter, faster, and more reliable offline selective soldering solution for today’s high-mix electronics manufacturing environments.

For more information about the Ultra Series or SASinno Americas’ full range of selective soldering equipment, visit www.sasinno.com.