Dymax, a global manufacturer of rapid and light-curing materials and equipment, is pleased to add 9773 ruggedizing and staking adhesive to its portfolio of materials designed for coating, protecting, and securing components on printed circuit boards in satellites, missiles, and space applications.

Dymax 9773 is certified to NASA ASTM E595 Low Outgassing and meets Mil-Std 883 Method 5011 Low Ionic Content standards, which help minimize PCB contamination for cleaner boards and higher reliability in extreme environments found in space.

The on-demand UV/Visible light cure of 9773 means printed circuit boards are processed quickly and as needed, eliminating racking, stacking, and waiting for alternative chemistries like two-part epoxies to cure. Faster processing and reduced work-in-process result in increased throughput.

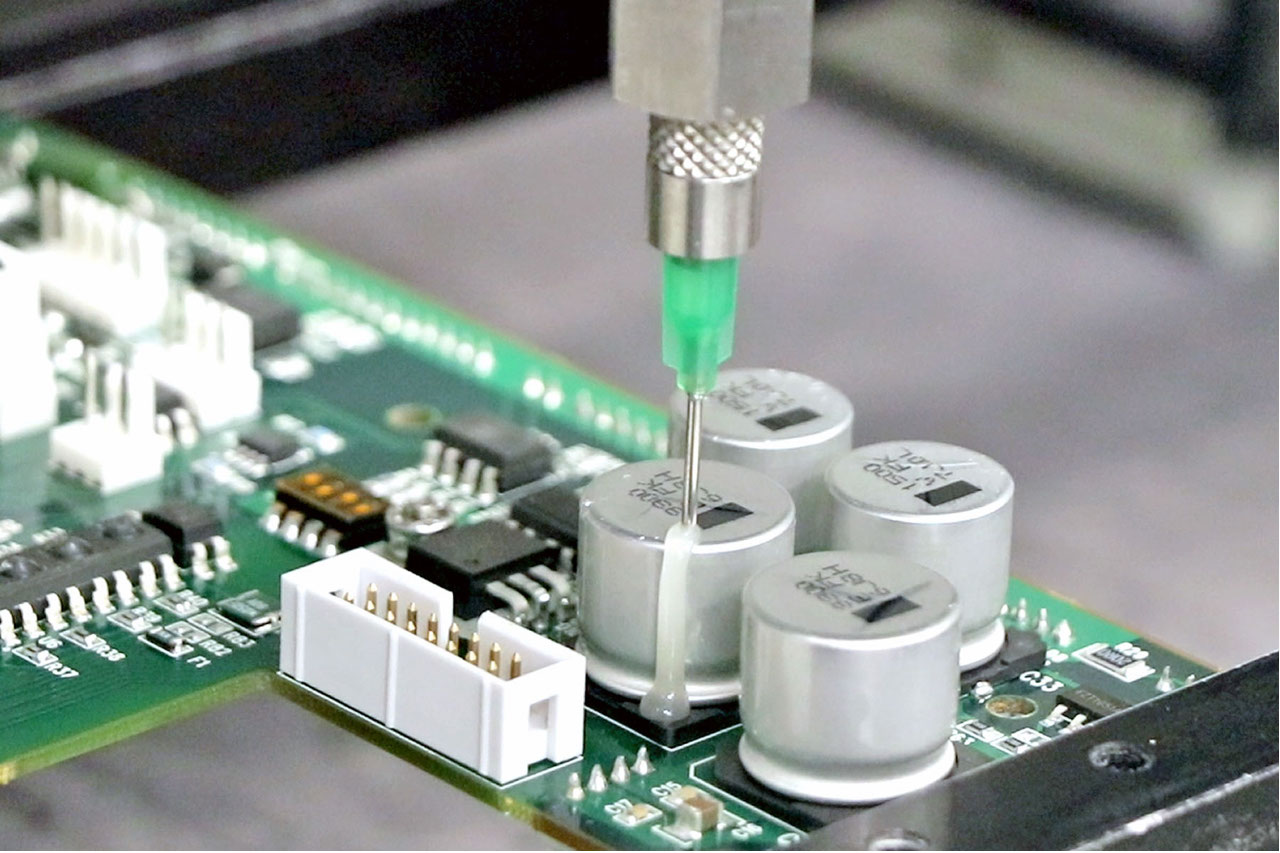

The adhesive is non-slumping on vertical surfaces up to 72 hours, jetting compatible for easy dispensing, and well-suited for ruggedizing, staking, or encapsulating PCB components. 9773 also complies with ASTM E595 with MAPTIS Material Code 09907.

With its one-part formulation, no solvents added, and halogen-free properties, the adhesive is a good choice for companies seeking to support their sustainability initiatives.

Dymax introduces 9773, a low-outgassing, ruggedized adhesive for advanced military and space applications.

About Dymax

Dymax develops innovative rapid and light-curable materials, dispense equipment, and UV/LED light-curing systems. The company’s adhesives, coatings, and equipment are perfectly matched to work seamlessly with each other, providing design engineers with tools to dramatically improve manufacturing efficiencies. Major markets include aerospace and defense; medical device; and consumer and automotive electronics.