GÖPEL electronic is bringing fresh ideas for quality assurance in electronics manufacturing to Productronica 2025 in Munich (Hall A2, Booth 239). On display will be powerful innovations for automatic optical (AOI) and X-ray inspection (AXI), modern in-system programming, and versatile JTAG/boundary scan systems. Future users will benefit from accuracy, efficiency, and adaptability for manufacturing that meets tomorrow’s requirements—from precise and secure failure detection to flexible programming.

In the field of inspection solutions, the focus is on four new products: With the Multi Line AXI, GÖPEL electronic is presenting a completely new generation of automatic X-ray inspection devices. For the first time worldwide, the system features hybrid X-ray technology that combines area and line detectors. This allows extremely high-resolution CT X-ray images to be generated in the shortest possible time. Thanks to a novel design and the resulting variability, both very large and heavy PCBA, such as those used in power electronics, and very small, stamp-sized circuit boards can be transported and inspected.

The company is also presenting a technology for novel, optimal illumination of PCBA at THT placement stations in the expanded model of the Multi Line Assist: MagicLight uses special illumination with coded light, which enables even the smallest or previously reflective details to be detected and eliminates interfering light. The new Multi Line CCI system is the first to implement 3D layer thickness measurement, revolutionizing the inspection of protective coatings. The new X250 camera module for inspecting SMD PCBA is now available for the Vario Line and Basic Line AOI systems. The new camera technology integrated in this module offers an increased resolution of 9.8µm without compromising speed.

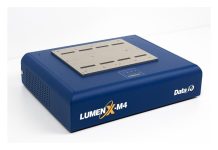

As a leading provider of JTAG/boundary scan, GÖPEL electronic is also presenting new solutions for this market segment at the trade fair: The FlashFOX in-system programmer is now also available in a dual-channel version. The universal programmer has two asynchronous parallel channels and four independently integrated power supplies for the targets to be programmed. It thus complements the existing 4- and 8-channel versions for small series, manual production stations, or development applications. To demonstrate the versatile applications of boundary scan and the proven SYSTEM CASCON software, GÖPEL electronic has developed the EJS Coach, a multifunctional demo board. In combination with the flexible BoardGrabber board holder, a wide range of embedded JTAG scenarios can be simulated realistically. In addition, GÖPEL electronic is presenting the JULIET Series 3, a professional, production-ready JTAG/boundary scan tester that combines system electronics and test object adaptation via interchangeable cassettes in a single complete device.

About GÖPEL electronic

GÖPEL electronic develops and manufactures innovative electrical and optical test, measurement, and inspection equipment for electronic components and printed circuit board assemblies as well as industrial and automotive electronics systems. GÖPEL electronic has four business units:

– Automotive Test Solutions

– Embedded JTAG Solutions

– Inspection Solutions AOI-AXI-SPI-IVS

– Industrial Function Test

The company is active worldwide, with its own subsidiaries as well as through distributors, and generated sales of approximately 40 million euros in 2023 with 240 employees.

Further information: www.goepel.com/en