Circuit Technology Center, Inc., a leader in circuit board rework, repair, and modification, is pleased to announce the addition of two new Hentec/RPS Odyssey 1325 robotic hot solder dip component lead tinning machines to its production floor. This expansion increases the company’s total robotic tinning capacity to six machines, significantly boosting throughput for high-reliability applications.

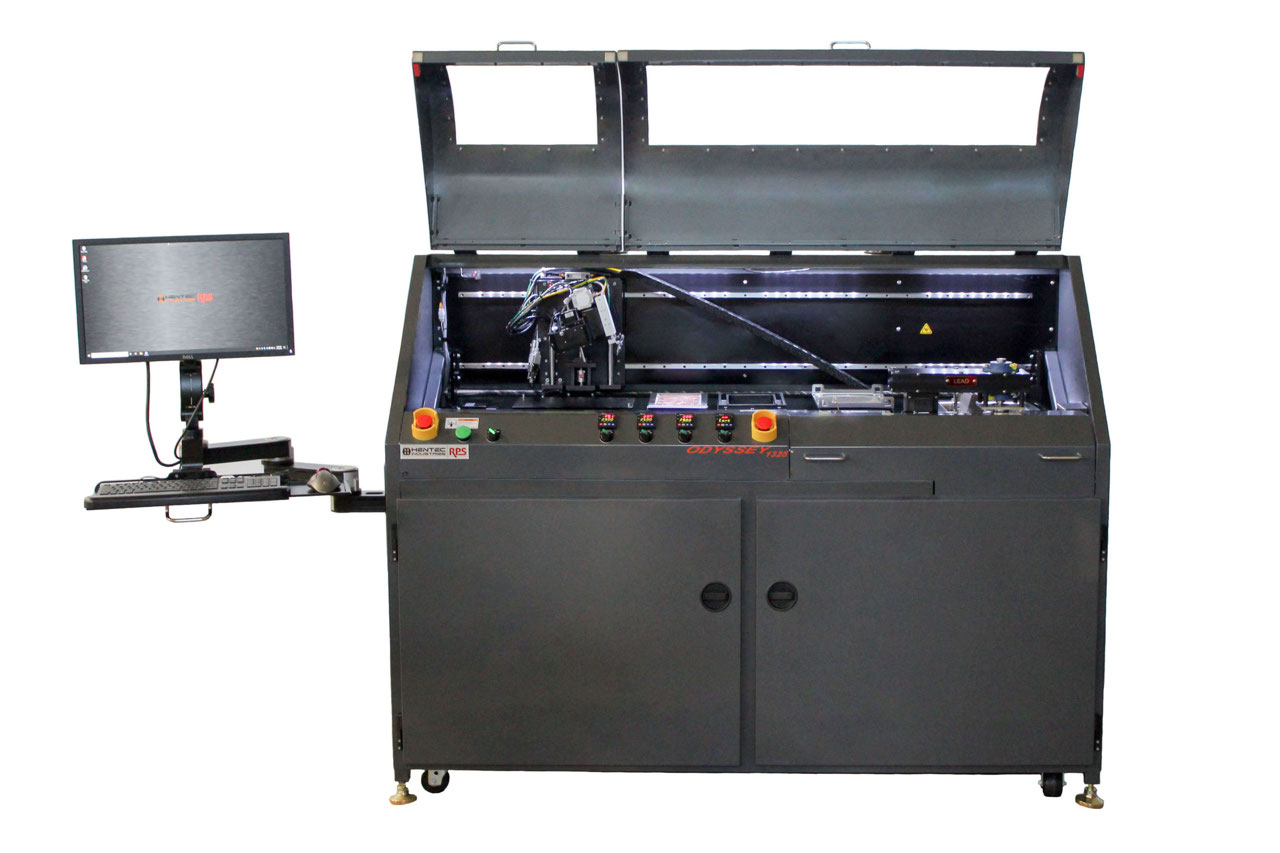

The Odyssey 1325 is a MIL-spec compliant, high-volume, high-mix lead tinning system equipped with auto load/unload functionality and capable of processing dual solder alloys. Designed for component lead reconditioning, gold removal, and re-tinning, it supports a wide range of component types, including DIP, SIP, QFP, BGA, axial, and radial components, as well as BGA de-balling. Each machine complies with GEIA-STD-006, MIL-PRF-38535, MIL-PRF-38524E, and ANSI-J-STD-002 standards.

“This investment strengthens our ability to deliver fast-turn, high-reliability tinning services to our commercial, medical, aerospace, and military customers” said Jeff Ferry, President of Circuit Technology Center. “By doubling down on robotic automation, we’re ensuring unmatched consistency, compliance, and capacity for the most demanding applications.”

With six Odyssey 1325 systems in operation, Circuit Technology Center reinforces its position as one of the most capable and responsive component lead tinning providers in the industry.

Circuit Technology Center, founded in 1979, continues to be recognized as the most innovative and reliable specialist in circuit board damage repair, rework, BGA re-balling and component level modification services in the world.