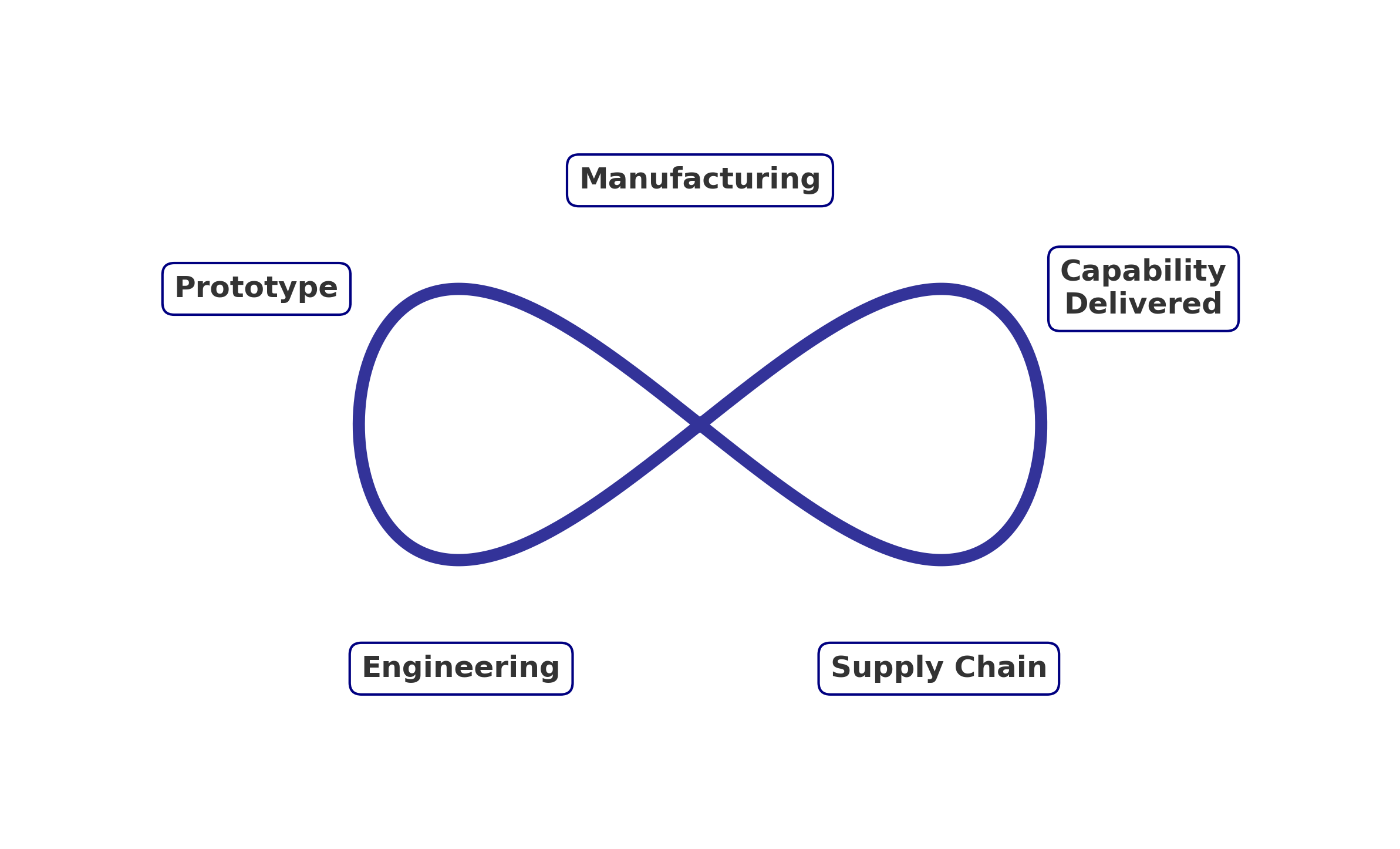

Innovation doesn’t start at production, and it doesn’t end with a build. It begins with the first prototype and ends only when capability is delivered reliably, repeatedly, and at the pace the mission demands (Figure 1).

That journey crosses engineering, manufacturing, and supply chain, functions that often operate in silos. The advantage comes when a single partner can unify them under one lifecycle approach. Whether you’re sourcing PCBA, RF assemblies, or both, the challenge is the same: compress the loop between concept and deployment without compromising rigor.

Why Lifecycle Thinking Matters

Early engagement during rapid prototyping sets the trajectory. This is where latent risks surface: component tolerances that collide, stack-ups that drift, RF chains that look clean in simulation but misbehave under real-world parasitics. Partners who understand this phase don’t just solder boards; they close the loop between engineering and manufacturing through design for manufacturability (DFM), fast iteration, and disciplined processes that prevent tomorrow’s failures today.

As designs mature into development, the center of gravity shifts from speed to stability without losing agility. That’s where the right partner makes the difference:

- Complex PCBA Assemblies: Building mission-critical electronics isn’t about volume, it’s about precision under complexity. These assemblies often combine fine-pitch BGAs, high-layer-count boards, and mixed technologies such as SMT, through-hole, and microelectronics. Add requirements like conformal coating, underfill, selective solder, and stringent cleanliness standards, and the margin for error disappears. Programs in defense, aerospace, and medical markets demand this level of rigor, where every interconnect and process step must perform flawlessly across environmental extremes.

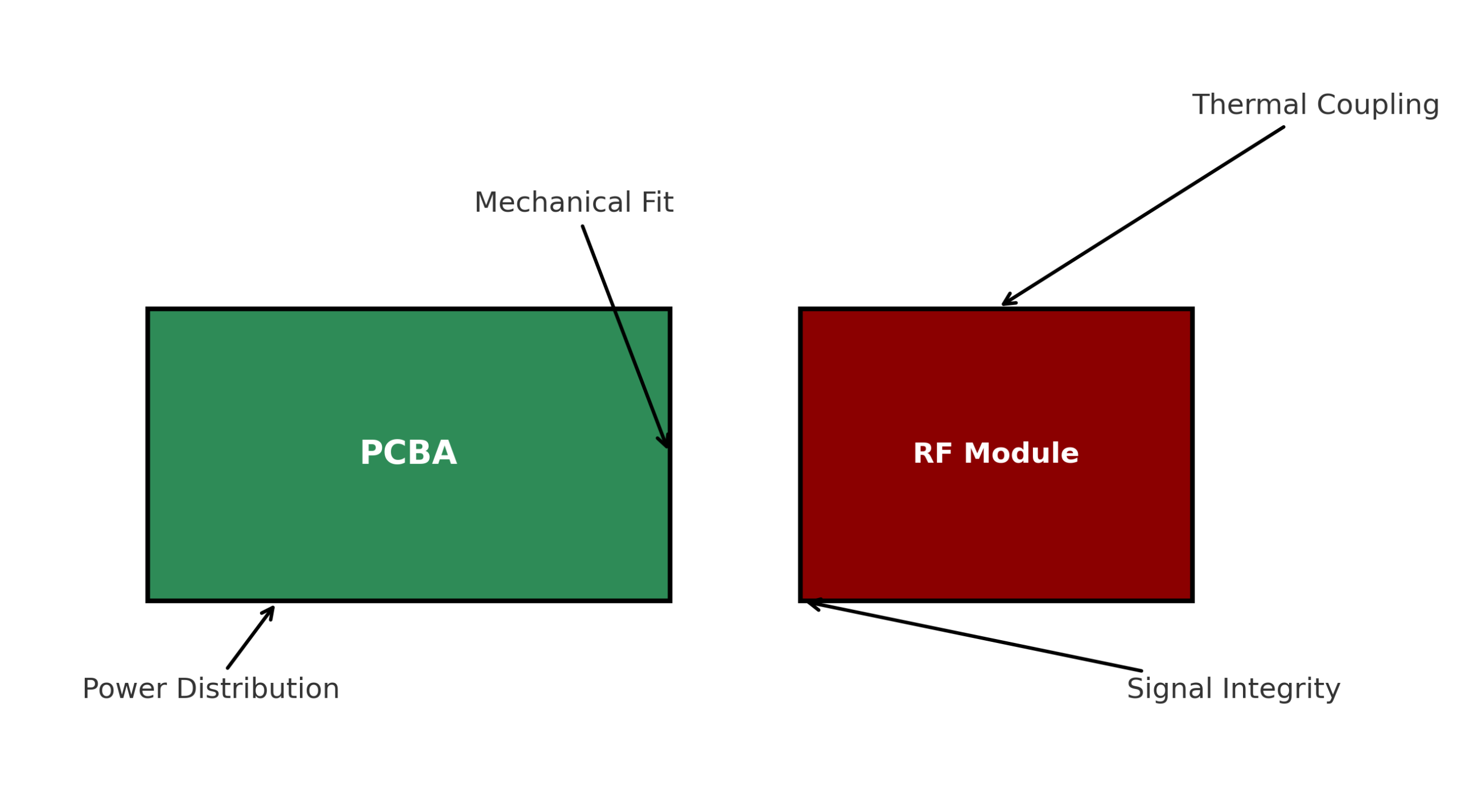

- Integrated Assembly Leadership: Programs that combine PCBA with RF assemblies and critical components introduce a new layer of complexity: mechanical fit, thermal coupling, signal integrity, and power distribution all converge (Figure 2). Managing these cross‑domain dependencies across multiple vendors multiplies risk and cost. A single partner that can deliver fully integrated assemblies eliminates handoff friction, accelerates schedules, and reduces the hidden costs of late-stage troubleshooting. This isn’t just convenience, it’s risk mitigation.

- Supply Chain Agility: Proactive sourcing and obsolescence planning mitigate risk before it impacts schedules, especially for legacy RF components that can derail timelines.

- Secure, Compliant Operations: ITAR-compliant, U.S.-based facilities safeguard sensitive programs while accelerating time-to-mission.

Obsolescence: the Hidden Schedule Killer

Obsolescence planning starts in development, not after the first article. And it means more than a spreadsheet of alternates. Many legacy RF components, diodes, limiters, and attenuators, have been priced out of the market or abandoned by their original suppliers, creating hidden schedule risk. A lifecycle-oriented partner that can design, qualify, or supply these critical parts eliminates that risk, shortens lead times, and keeps next generation performance on track.

The Lowest Price Technical Acceptable (LPTA) Trap

The hard truth is the LPTA mindset is the enemy of lifecycle success. On paper, compliance looks safe. In practice, it strips out the early engagement, the design feedback, the obsolescence planning, and the integration discipline that prevent catastrophic surprises later.

It also ignores something harder to quantify but just as critical: cultural alignment. When a partner is engaged from prototyping through development, they don’t just learn the design, they learn the mission, the priorities, and the decision-making rhythm of the customer. That shared context builds trust and accelerates problem-solving when the stakes are highest. LPTA sourcing disrupts continuity, shifting from a collaborative to a transactional culture. Lowest price rarely equals lowest risk, especially when the cost of failure is measured in missions missed, payloads lost, or patients harmed.

What Good Looks Like

Lifecycle thinking isn’t a slogan; it’s an operating model. Five commitments separate programs that deliver on time from those that don’t:

- Engage early, stay late. Manufacturing shows up at concept, not at PO.

- Design for resilience. Build obsolescence roadmaps on day one, including critical RF components if they are part of the assembly.

- Engineer for manufacturability. Every design decision should accelerate production without sacrificing performance.

- Maintain continuity. Keep the same cross-functional team engaged from prototype through production.

- Measure by capability delivered. Shift KPIs from “parts completed” to “mission enabled.” That small change in vocabulary drives a big change in behavior.

The Takeaway

If you lead a program, structure procurement and engineering to the lifecycle:

- Fund early integration. Treat it as baseline program structure, not a discretionary activity.

- Instrument delivery risk. Measure first-pass yield, ECO cycle time, and environmental screen margins.

- Make obsolescence proactive. Make plans part of the baseline, not a change order.

- Prioritize cultural alignment. Continuity from prototype through deployment reduces friction and speeds decisions.

Innovation compounds when we stop treating builds as transactions and start treating them as phases in a continuum. Whether your need is PCBA, RF, or both, the principle holds: capability delivered beats compliance awarded. The organizations that internalize that truth, and align sourcing to it, will quietly power the future.

For more information, contact President & CEO Teh-Kuang Lung at Naprotek, LLC at www.naprotek.com.